Ice breaker and snow blower

A snow blower, ice and snow technology, applied in the direction of snow cleaning, cleaning methods, construction, etc., can solve the problems of reduced operating efficiency and quality, difficult adjustment, unstable speed, etc., to ensure the quality and effect of the operation, adjust Simple and convenient, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

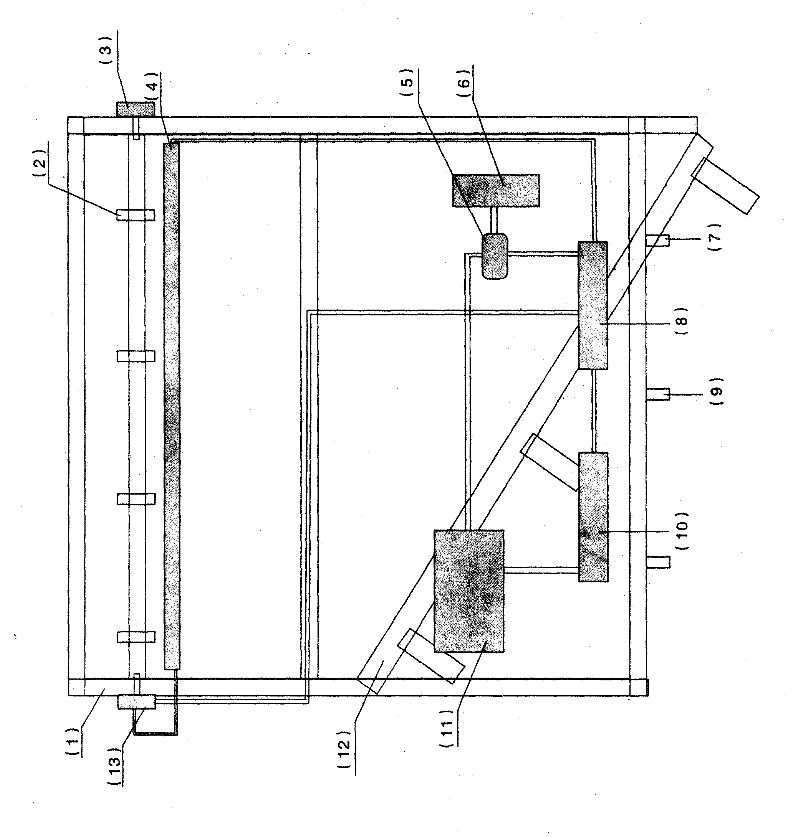

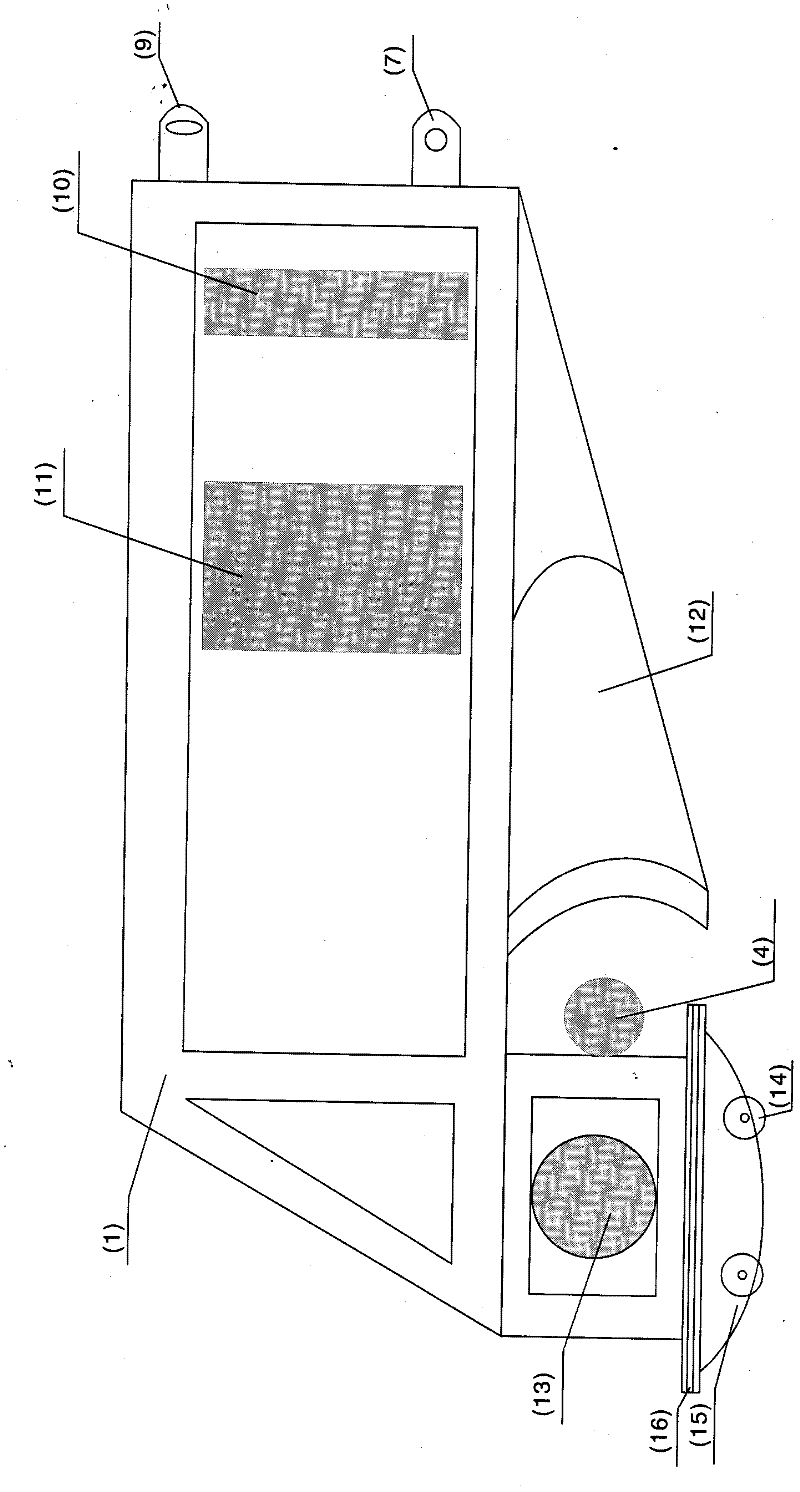

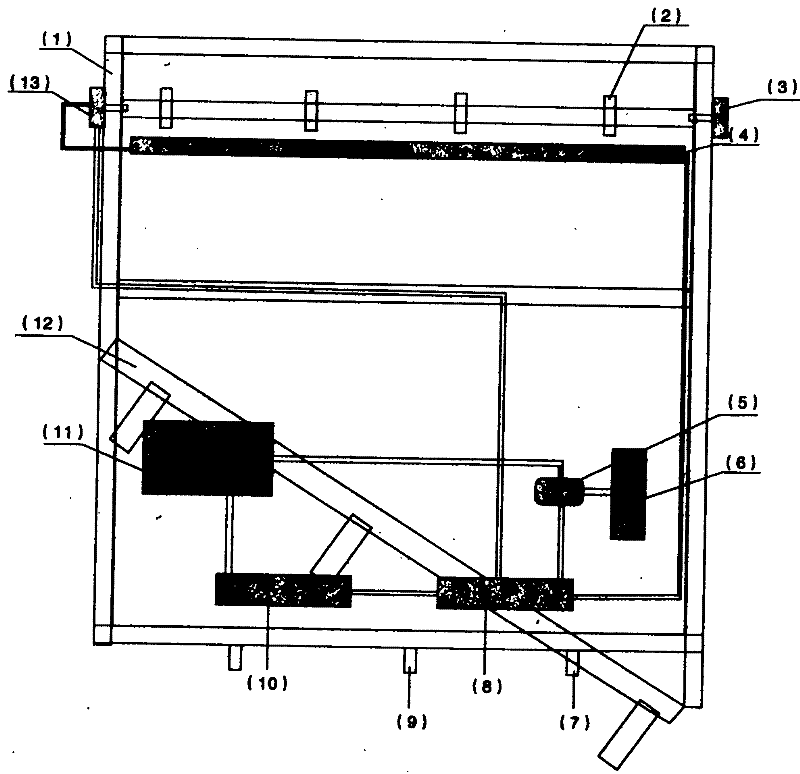

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The ice-breaking and snow-cleaning machine includes a frame assembly 1, the ice-breaking and snow-breaking shaft assembly 2 and the ice-snow scraping and moving shovel 12 are equipped on the lower side of the frame assembly 1, and the hydraulic motor 13 is fitted on the ice-breaking and snow-breaking shaft assembly 2- On the side end, engine 6, hydraulic oil pump 5, distributor 8, hydraulic oil tank 11 are equipped on the upper side of frame assembly 1, engine 6 is connected with hydraulic oil pump 5, oil pipe connects hydraulic oil pump 5 and hydraulic oil tank 11 respectively It communicates with the distributor 8 and the distributor 8 is connected with the hydraulic motor 13. An upper lifting lug 9 and two lower lifting lugs 7 are installed on the rear end of the frame assembly 1. On the lower side of the frame assembly 1 1. A natural cooling heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com