A multi-stage double-acting oil cylinder for a hydraulic road lifter

A double-acting oil cylinder and road lifter technology, applied in the direction of fluid pressure actuating devices, can solve the problems of unsatisfactory requirements, low work efficiency, digging heavy pits, etc., and achieve easy processing and manufacturing, high working pressure, and ejection powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

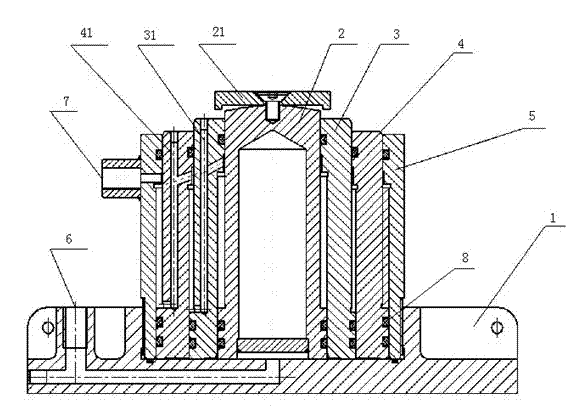

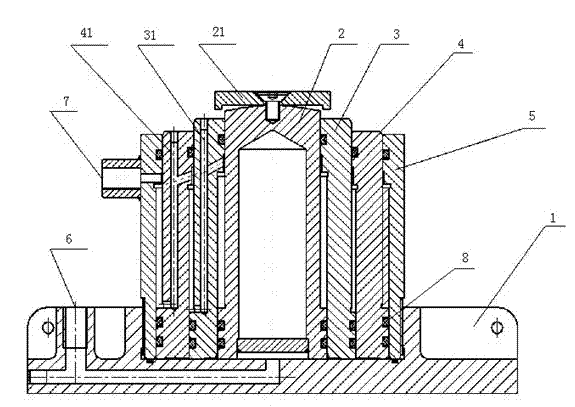

[0015] as the picture shows,

[0016] The embodiment of the present invention is mainly composed of a bottom plate 1, a central plunger 2, a first cylinder 3, a second cylinder 4, and a third cylinder 5. Wherein, a first oil passage 31 is provided in the wall of the first cylinder 3 , and a second oil passage 41 is provided in the wall of the second cylinder 4 . There are two oil inlets (also used as oil return ports) of the present invention, the first oil inlet 6 communicates with the center plunger barrel 2, the second oil inlet 7 passes through the wall of the third cylinder 5 and connects with the second The oil passage 41 communicates with the first oil passage 31 , and the upper end of the center plunger is connected with the top supporting plate 21 . In addition, sealing rings 8 are provided on the upper and lower parts of the inner wall of the first cylinder, the second cylinder and the third cylinder.

[0017] Below again in conjunction with accompanying drawing, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com