Line sheath

A sheathing and line technology, applied in the field of wires and cables, can solve the problems of exposed inner core wires of the outer sheath, hidden dangers, easy winding and knotting, etc., and achieves the effects of simple structure, flexible and convenient use, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

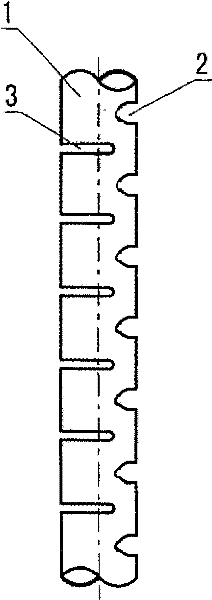

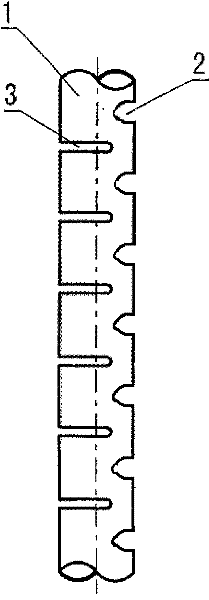

[0013] Example 1: See figure 1 As shown, a line sheathing tube includes a circular PE plastic tube body 1, one side of the PE plastic tube body has a longitudinal oval hole 2 running through the head and tail of the tube body, and the oval hole on the tube body is The opposite side of 2 has a long and narrow slit 3 extending along the circumferential direction of the cross-section of the pipe body, and the length of the long and narrow slit 3 is 2 / 3 to 3 / 4 of the circumferential length of the cross-section of the pipe body.

Embodiment 2

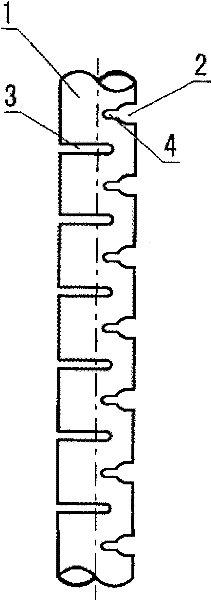

[0014] Example 2: see figure 2 As shown, a line sheathing pipe includes a circular PE plastic pipe body 1, one side of the PE plastic pipe body has a longitudinal oval hole 2 running through the head and tail of the pipe body, and the longitudinal oval hole of the pipe body is On both sides of the hole 2 there are long and narrow openings 4 extending along the circumferential direction of the cross section of the pipe body, and on the opposite side of the oval hole 2 on the pipe body there are long and narrow slits extending along the circumferential direction of the cross section of the pipe body 3. The long and narrow openings 4 and the long and narrow slits 3 are arranged alternately in the longitudinal direction of the pipe body 1, and the length of the long and narrow slits 3 is 2 / 3 to 3 / 3 of the circumference length of the cross-section of the pipe body. 4.

[0015] In actual use, the opening of the wire gripper faces the user himself, and makes it close to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com