Disposable diapers and sanitary napkin liners with improved skin affinity

A sanitary napkin, a disposable technology, used in transportation and packaging, medical science, bandages, etc., can solve the problem of sweating is not easy to discharge, to achieve easy drying, reduce hair loss, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

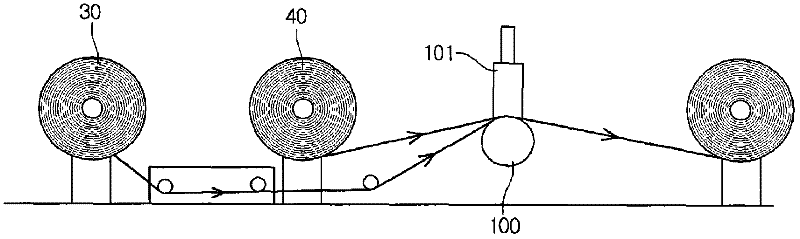

[0062] Manufacture of lining materials (perforation of hydrophobic nonwovens and lamination of absorbent nonwovens)

[0063] The weight of hydrophobic non-woven fabric is 13g / m 2 polypropylene spunbond nonwoven fabric.

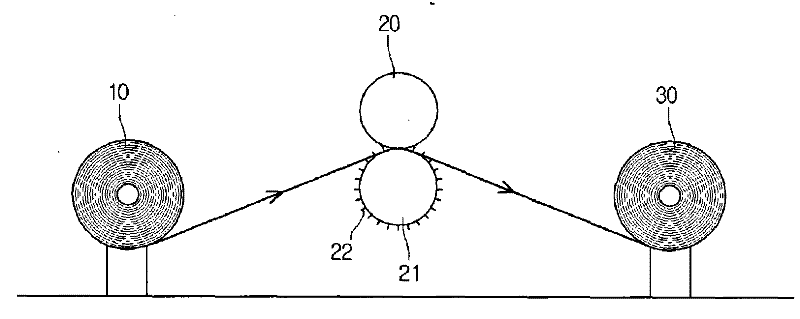

[0064] Pin flushing takes place via pin rollers.

[0065] As the pin roll, a pin roll having a pin body area accounting for 42% of the bottom surface area of the pin roll was used.

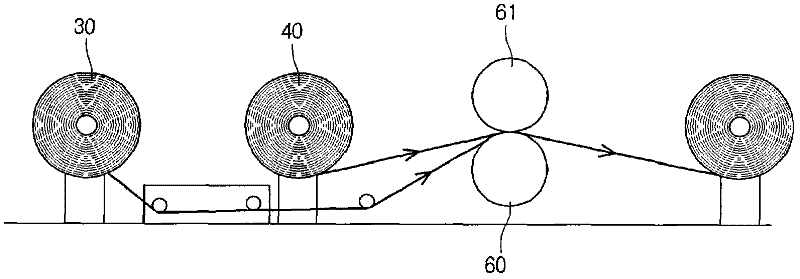

[0066] The hydrophobic perforated non-woven fabric is ultrasonically bonded with a weight of 20g / m 2 Hydrophilic air-treated nonwoven embossed laminate.

[0067] The lamination embossing roll bonding pattern used a diamond wire pattern with a length of four sides of 7 mm and a line width of 1 mm.

[0068] Bonding of hydrophobic perforated nonwovens and hydrophilic nonwovens along a diamond linear bonding pattern.

[0069] (Test result of Example 1)

[0070] Linting of perforated nonwovens was compared before and after embossing lamination.

[0071] When rubbing by hand, i...

Embodiment 2

[0073] Except that in Example 1, the hydrophobic perforated nonwoven laminated paper towel (21g / m 2 ) and weight 20g / m 2 Except for the non-woven fabric of the hydrophilic ventilation treatment, the same method as in Example 1 was used to manufacture a non-woven lining.

[0074] The test result is similar to Example 1.

Embodiment 3

[0076] Manufacturing of diapers

[0077] Using the nonwoven liner of Example 1, disposable diapers were manufactured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com