A precision seeding machine for plug seedlings

A technology of plug seedling raising and seeding machine, which is applied in the direction of single seed seeding machine, planting method, excavation/covering trenches, etc., can solve complex problems, uneven return spring parameters, inability to suck seeds, etc., and achieve displacement resolution High efficiency, good frequency response, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

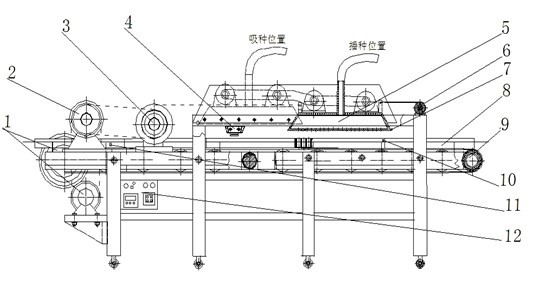

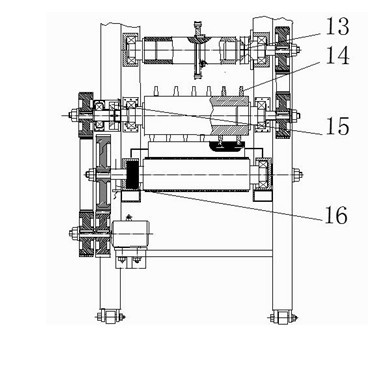

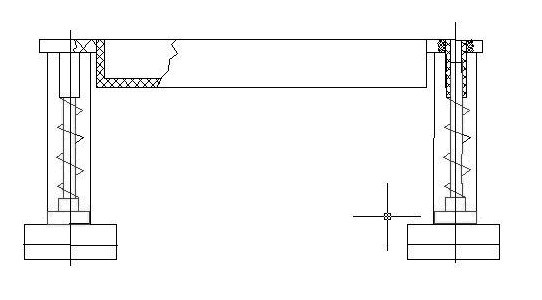

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Such as Figure 1a to Figure 5 As shown, a precision seeding machine for raising seedlings with plug trays includes a seed tray and its pneumatic components, a seed tray elastic return frame assembly 6, a vibration table assembly 4, a tray and its conveying mechanism assembly 9, a hole punching mechanism 2, The power drives the synchronous transmission system 1.

[0035] The power drive transmission system 1 consists of a 0.25kw model Co 2 .7124 speed-regulating motor, gear transmission mechanism 3, sprocket transmission mechanism and other components drive the seed suction tray 5, hole tray 8, and hole punching mechanism 2 respectively. 0.2kw electromagnetic clutch brake 13 and electromagnetic clutch brake 15 are housed respectively on the power transmission shaft of seed-suction disc 5 and hole punching mechanism 2. The electromechanical control system 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com