A small semi-automatic stevia leaf picker

A stevia, semi-automatic technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of low production efficiency, low degree of automation, poor safety, etc., to improve production efficiency, improve economic benefits, and reduce harvesting. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

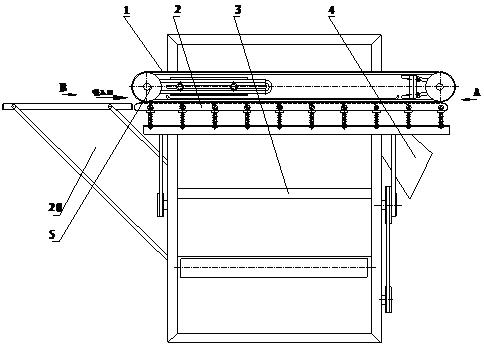

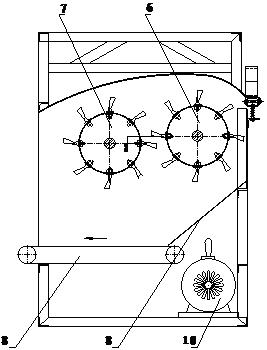

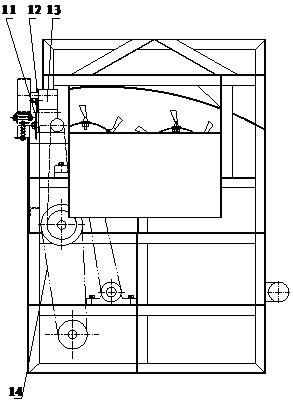

[0021] Small semi-automatic leaf picking machine, the frame 3 is crocodile type, which constitutes the feeding and discharging channels; there are two leaf picking rollers placed on the frame 3 parallel to the feeding direction, the height difference is 25~60mm, and there are 4- 6 comb teeth 17, 10-20 knife teeth 18, 4-6 discharge teeth 19; the flexible clamping chain 1 is located on the upper frame 3, and the supporting bracket 2 is located on the lower jaw of the frame 3, forming a part of the leaf removal process Clamping the manipulator, the clamped young shoots are automatically cut off when they encounter the upper and lower cutters, and automatically fall into the collection box. The leaves that have been taken off are automatically discharged out of the machine through the airflow and the conveyor belt 8 inside the machine, while the stems are in the main and auxiliary The discharge teeth 19 at the end of the cylinder 6 fall from the discharge slide 4 under the action. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com