Vegetable Dehydration Technology and Equipment by Thin-Layer Rapid Combination Heating

A vegetable dehydration, thin-layer technology, applied in the application, food processing, food science and other directions, can solve the problems of nutrient loss, poor color of dried vegetables, etc., and achieve the effect of strong convection, good quality of dried vegetables and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

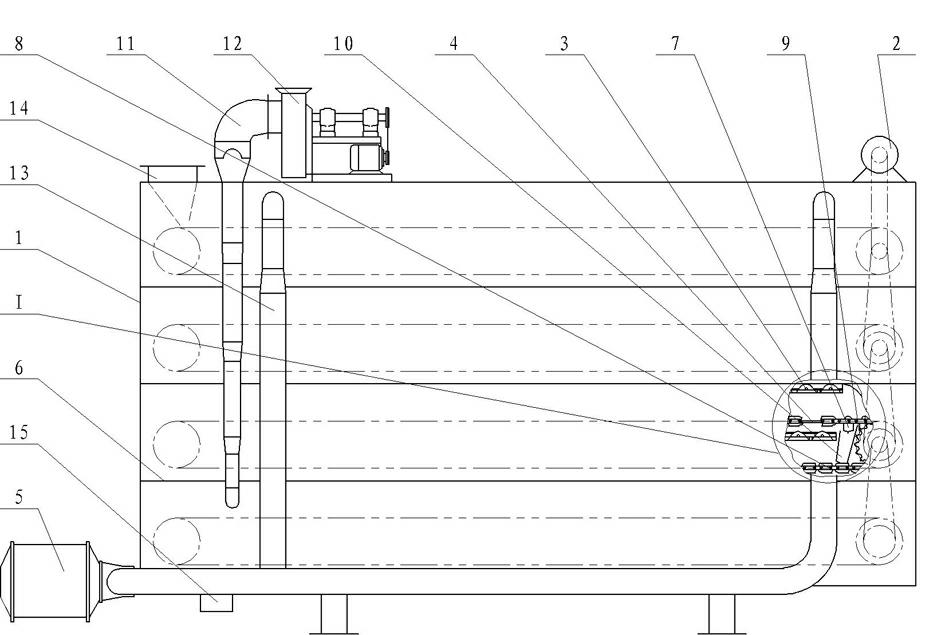

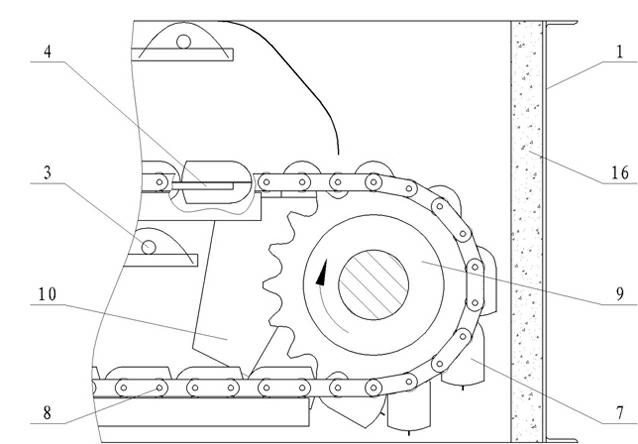

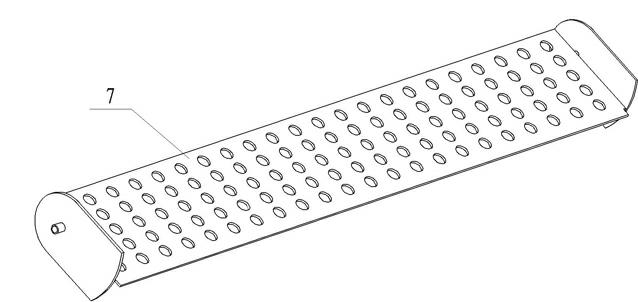

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Carrots are cut into filaments of 50 × 4 × 3mm, and the thickness of the material layer when dehydrating and drying is 15mm when adopting the thin-layer rapid combined heating and dehydration process, the total time used for dehydration and drying is 185min, and other dehydration and drying parameters are as shown in Table 1 Show.

[0021] Table 1 Dehydration and drying process parameters of carrots.

[0022]

Embodiment 2

[0023] Embodiment 2: Cabbage orchid is cut into filaments of 50 × 3mm, and the thickness of the material layer when dehydrating and drying is 18mm by using the thin-layer rapid combined heating and dehydration process, and the total time used for dehydration and drying is 170min. Other dehydration and drying parameters are shown in Table 2 .

[0024] Table 2 Dehydration and drying process parameters of cabbage.

[0025]

Embodiment 3

[0026]Embodiment 3: the cabbage pepper is cut into filaments of 40 × 3mm, and the thickness of the material layer when adopting the thin layer rapid combined heating and dehydration process for dehydration and drying is 16mm, and the total time used for dehydration and drying is 178min, and other dehydration and drying parameters are as shown in Table 3 Show.

[0027] Table 3 Dehydration and drying process parameters of cabbage pepper

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com