Fully Automatic Grinding Method for Vertical Internal and External Cylindrical Grinding Machine

An internal and external cylindrical grinding machine, fully automatic technology, applied in the field of control system, to achieve the effect of improving work efficiency, simplifying on-site operation and speeding up the application speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

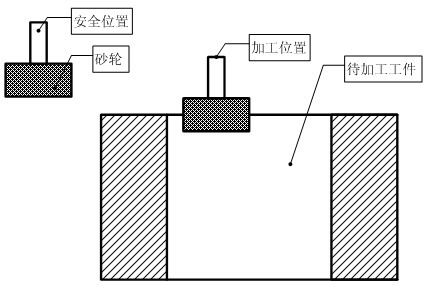

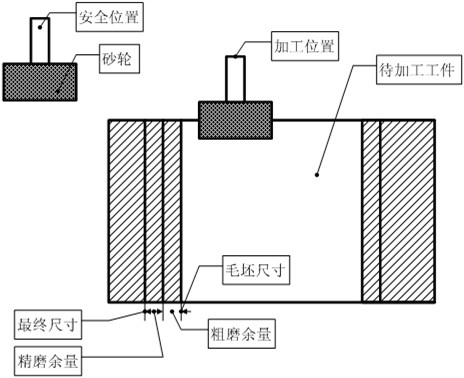

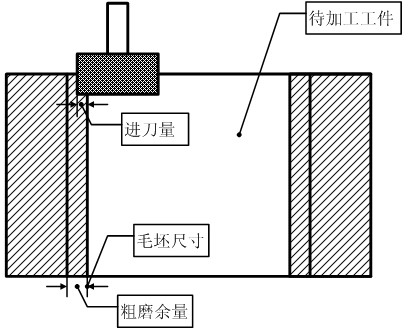

[0028] Method steps for automatic grinding of vertical internal and external cylindrical grinders: 1) Set the final size of the workpiece, the size of the workpiece blank, and the fine grinding allowance, and calculate the rough grinding allowance, and the rough grinding allowance = final size - workpiece blank size - fine grinding allowance Grinding allowance; 2) Set the number of times of coarse grinding and dressing, calculate the amount of coarse grinding, and then dress the grinding wheel. The grinding allowance of the grinding wheel to be dressed = grinding allowance of the grinding wheel ÷ times of dressing the grinding wheel 3) Set from top to bottom The feed amount at the bottom, the feed amount from bottom to top, the Z-axis starting coordinate, the Z-axis coordinate, the grinding speed and other grinding parameters, start the rough grinding of the workpiece; 4) When the coordinates of the grinding wheel need to be trimmed Finally, enter the dressing parameter setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com