Filling drum with inner film bag and aseptic and sealed filling process of a beverage

A film bag and filling technology, which is applied in the field of aseptic sealed filling technology of beverages, can solve problems such as secondary pollution of cleaning liquid, hidden dangers of hygiene and safety, and cost of bottled water, and achieve simple filling process and Low cost and less water consumption for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below through examples, which are only used to further illustrate the present invention, and should not be construed as limiting the scope of protection of the present invention. Technical engineers in this field can make some non-essential improvements and Adjustment.

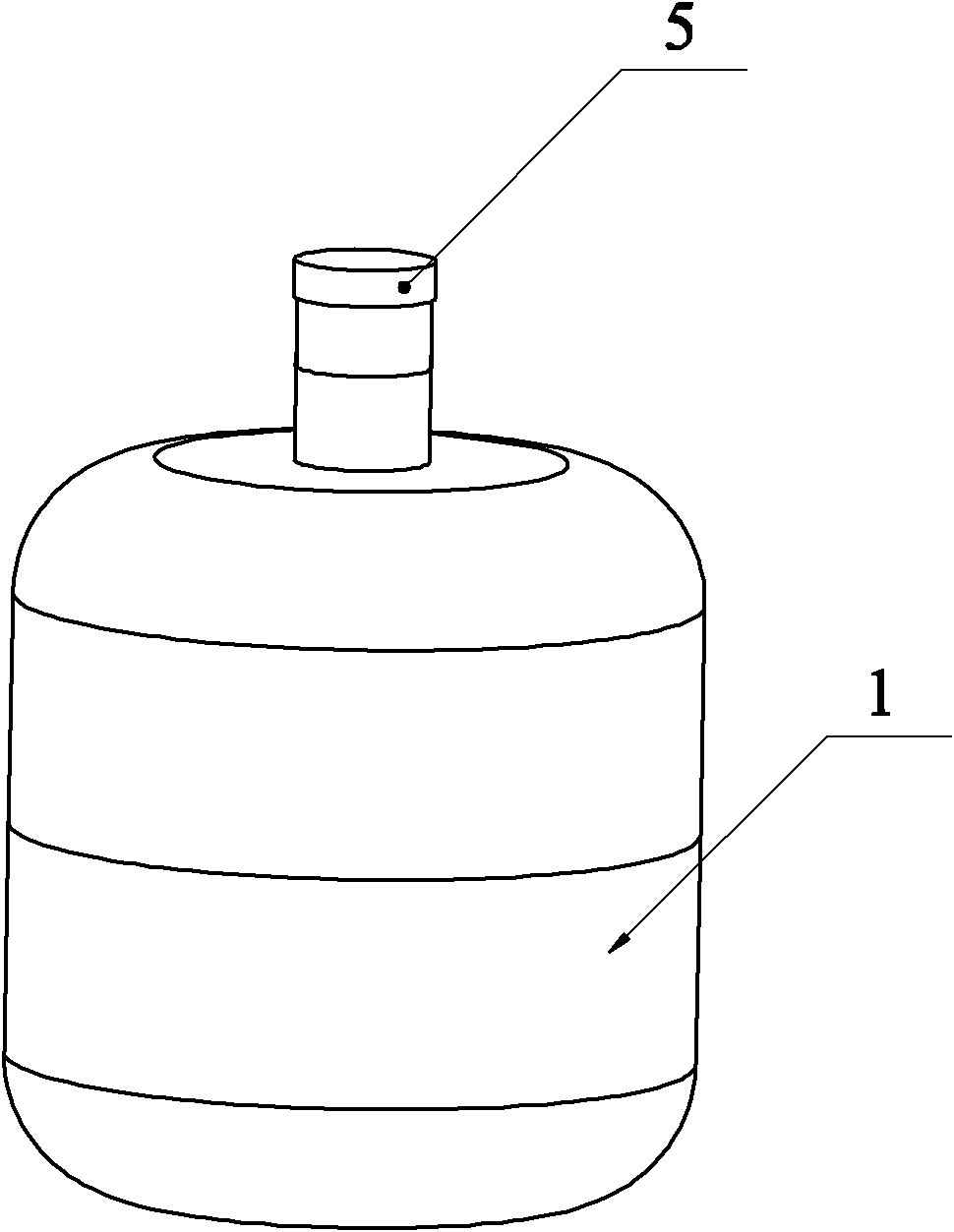

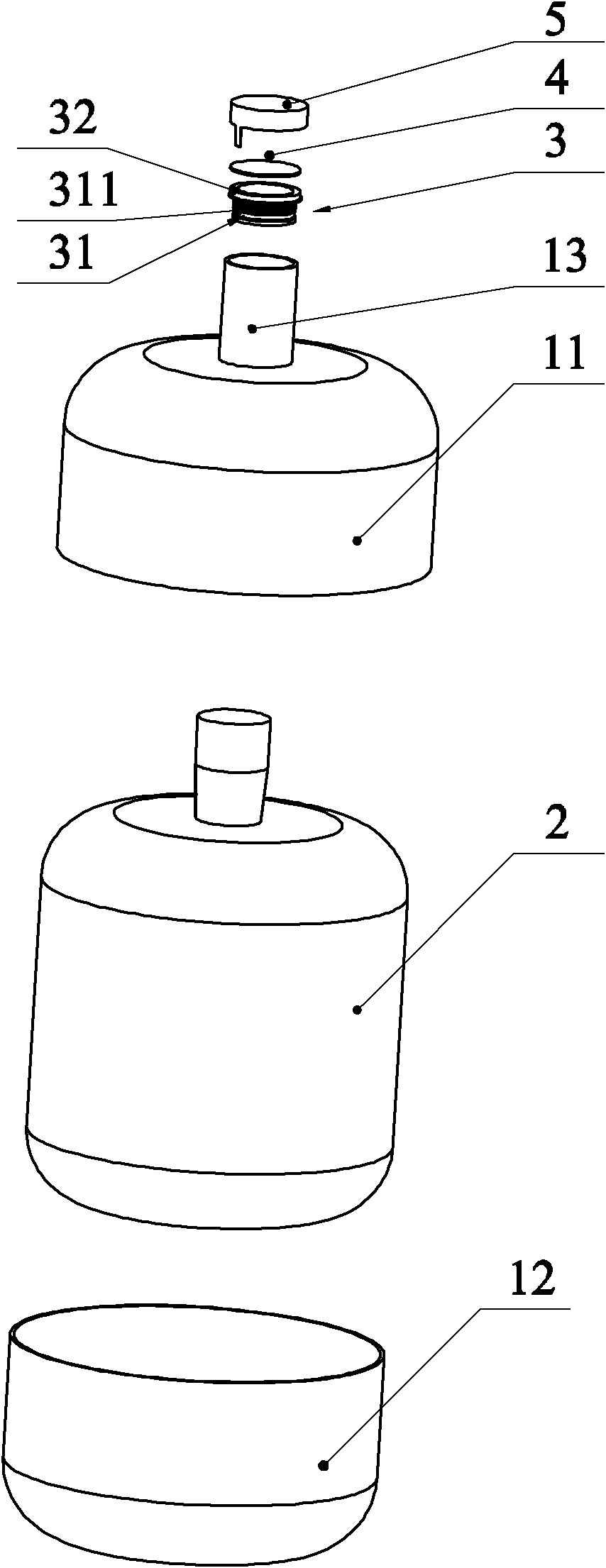

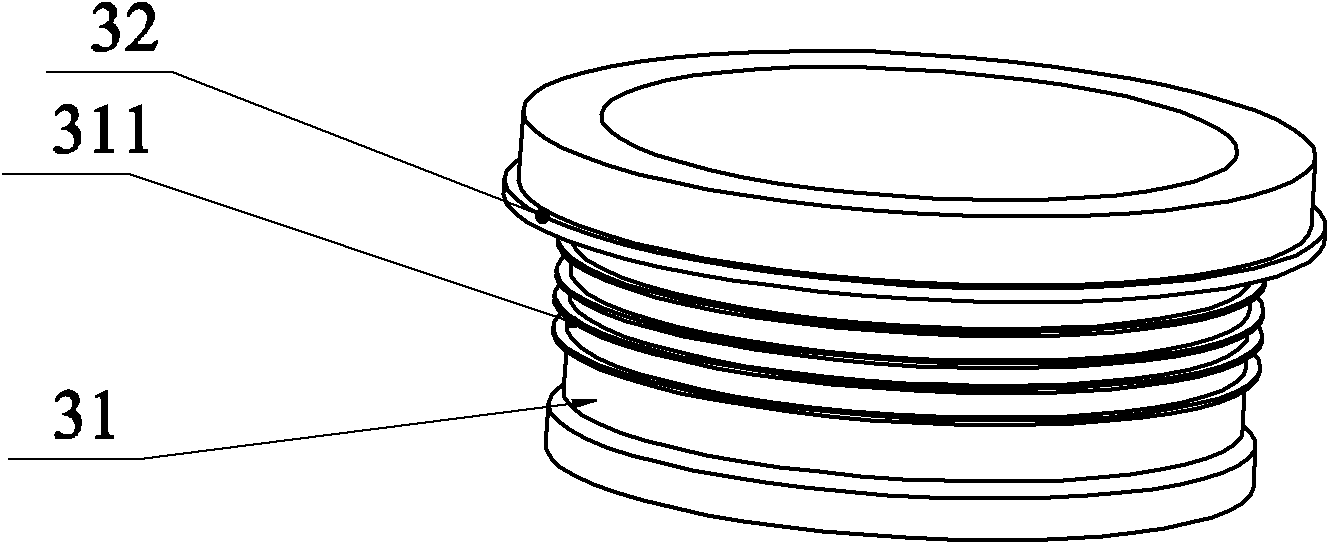

[0026] like Figure 1-3 The illustrated embodiment of the present invention includes a barrel body 1. The barrel body 1 described in this embodiment is formed by an upper barrel body 11 and a lower barrel body 12 being relatively butt-jointed, fixed and sealed (preferably by ultrasonic welding), so that The storage and transportation space is reduced. In addition, since the barrel body of the present invention is not in direct contact with drinking water, the material of the barrel body 1 can be made of materials such as PVC with high strength and low cost. There is an open pipe 13, the open pipe 13 is arranged on the upper barrel body 11, the open p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com