Combined cover for injection medicine bottle

An injection and combined cap technology, which is applied to the field of combined caps for injection medicine bottles, can solve the problems of high processing cost, waste of space, affecting the sealing effect, etc., so as to reduce processing equipment and process links, reduce production costs and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

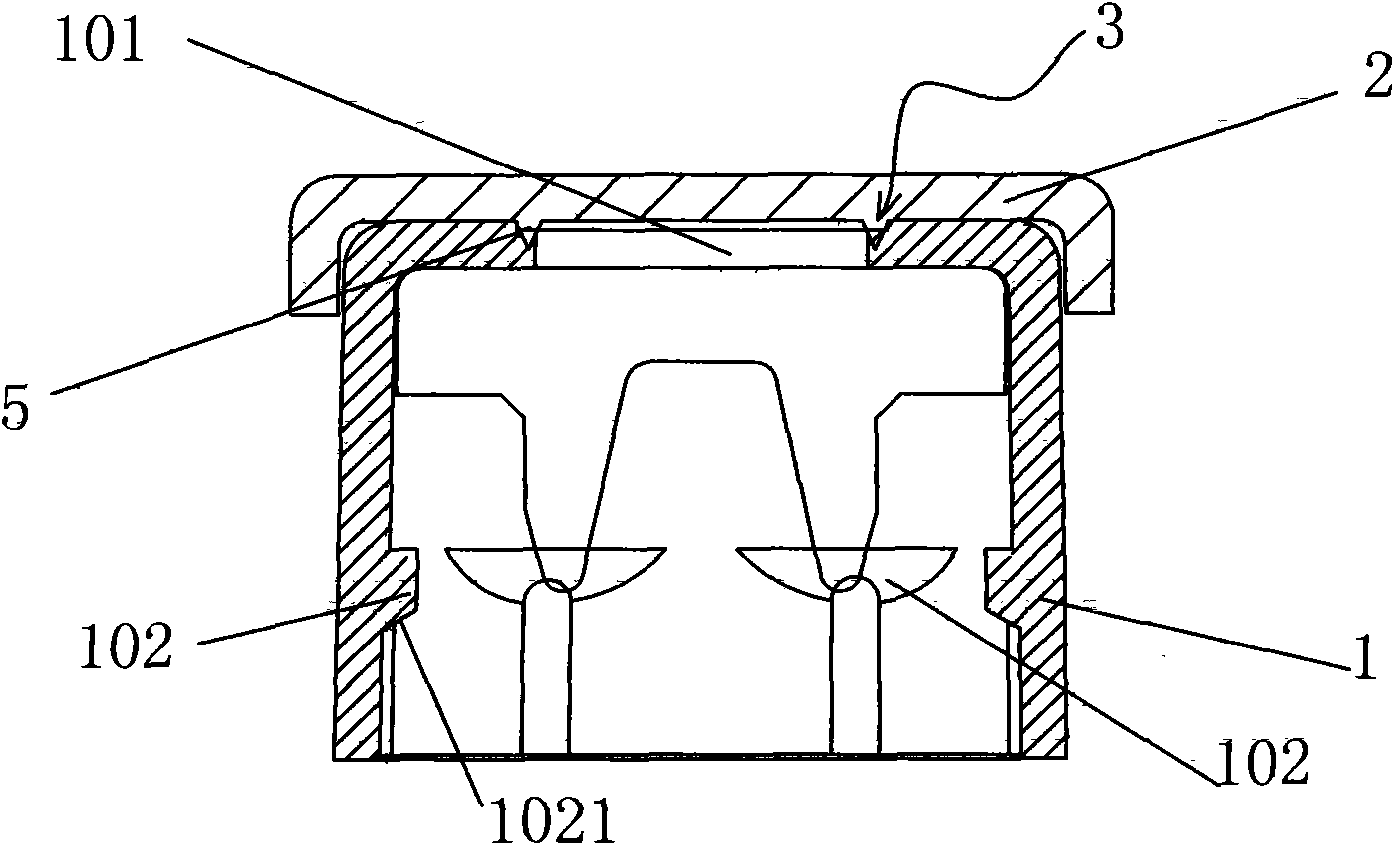

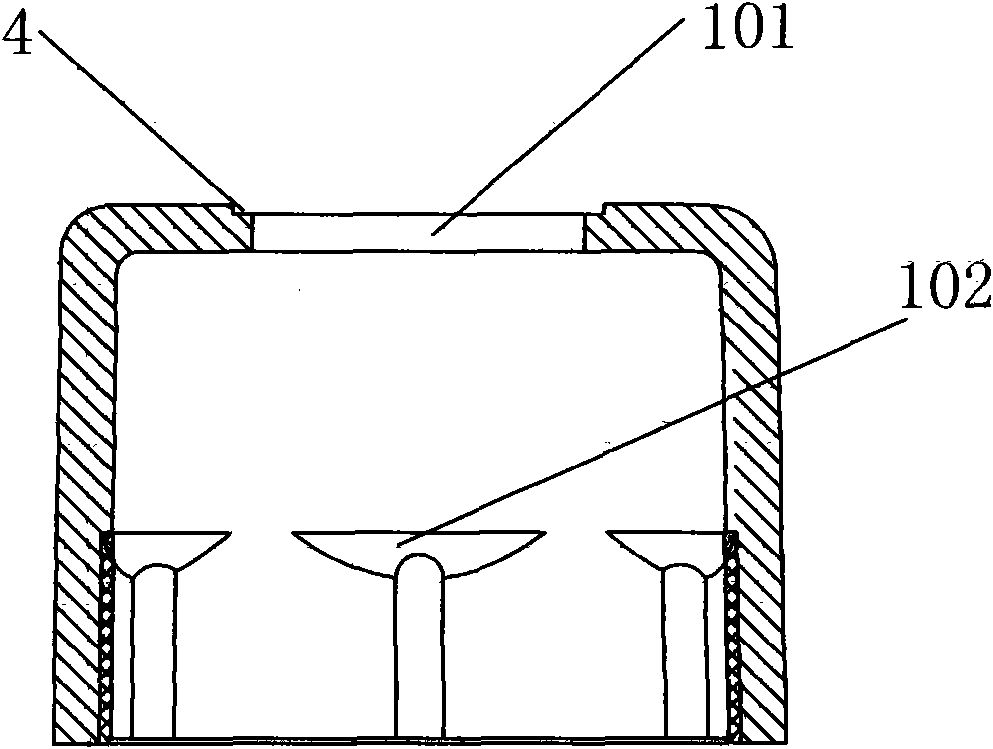

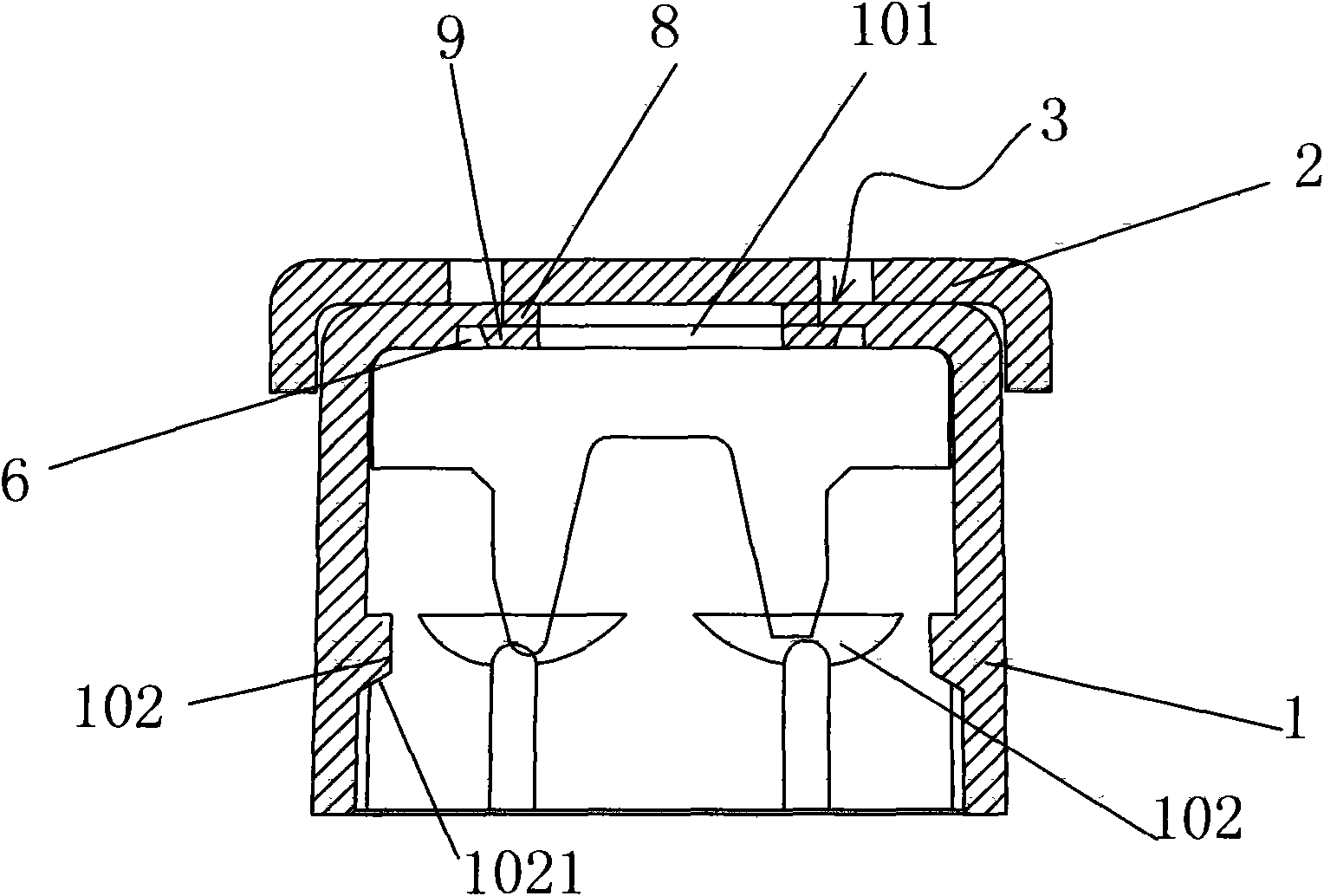

[0018] Such as Figure 1-4 As shown, the present invention is a combination cap for an injection medicine bottle, which includes a plastic main cover 1 that can be installed at the bottle mouth, and the plastic main cover 1 is provided with an opening 101 facing the bottle mouth sealing rubber plug. 1. The upper cover has a plastic auxiliary cover 2 that can be opened and separated from it. A sealing connection structure 3 is provided between the plastic auxiliary cover 2 and the opening 101 of the plastic main cover 1. Such a structure can prevent germs from contaminating medicines and is hygienic and safe. advantage.

[0019] Such as Figure 1-2 In the shown embodiment 1, the sealing connection structure 3 includes an annular connection platform 4 arranged around the opening 101 of the plastic main cover 1. A connecting ring 5 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com