Integrated cover assembly

A cover assembly and one-piece technology, applied in the field of one-piece cover assembly, can solve the problems of high manufacturing cost, achieve the effects of low production cost, convenient use, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

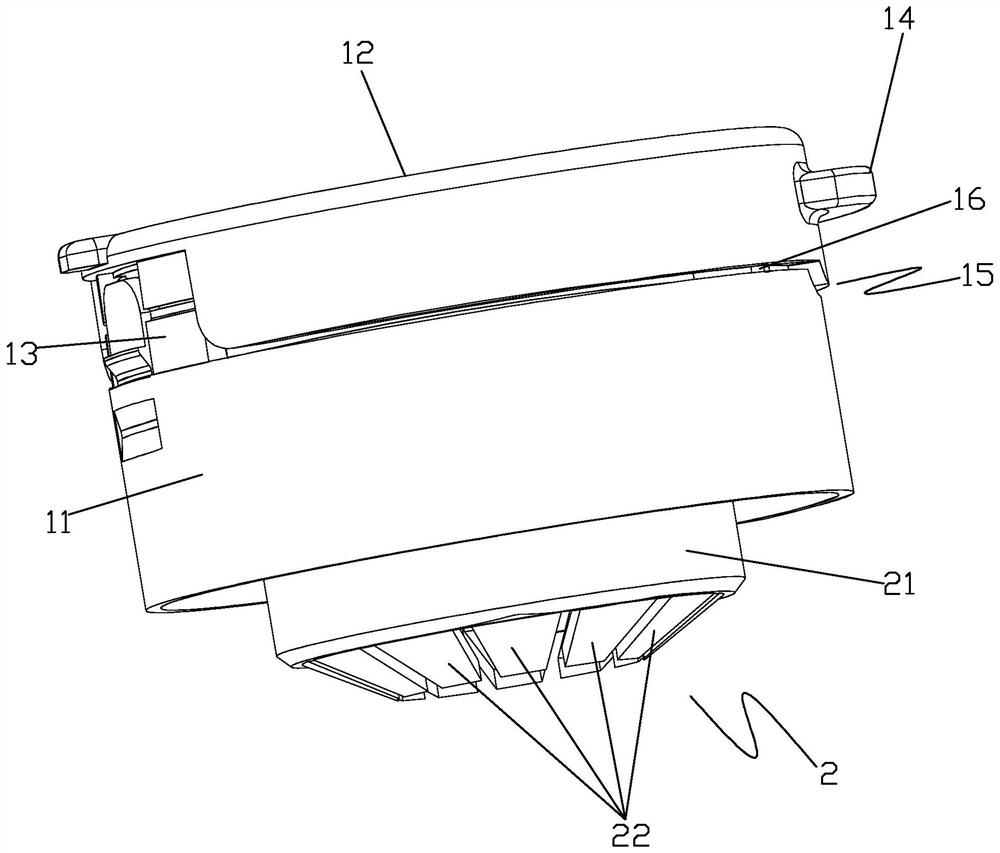

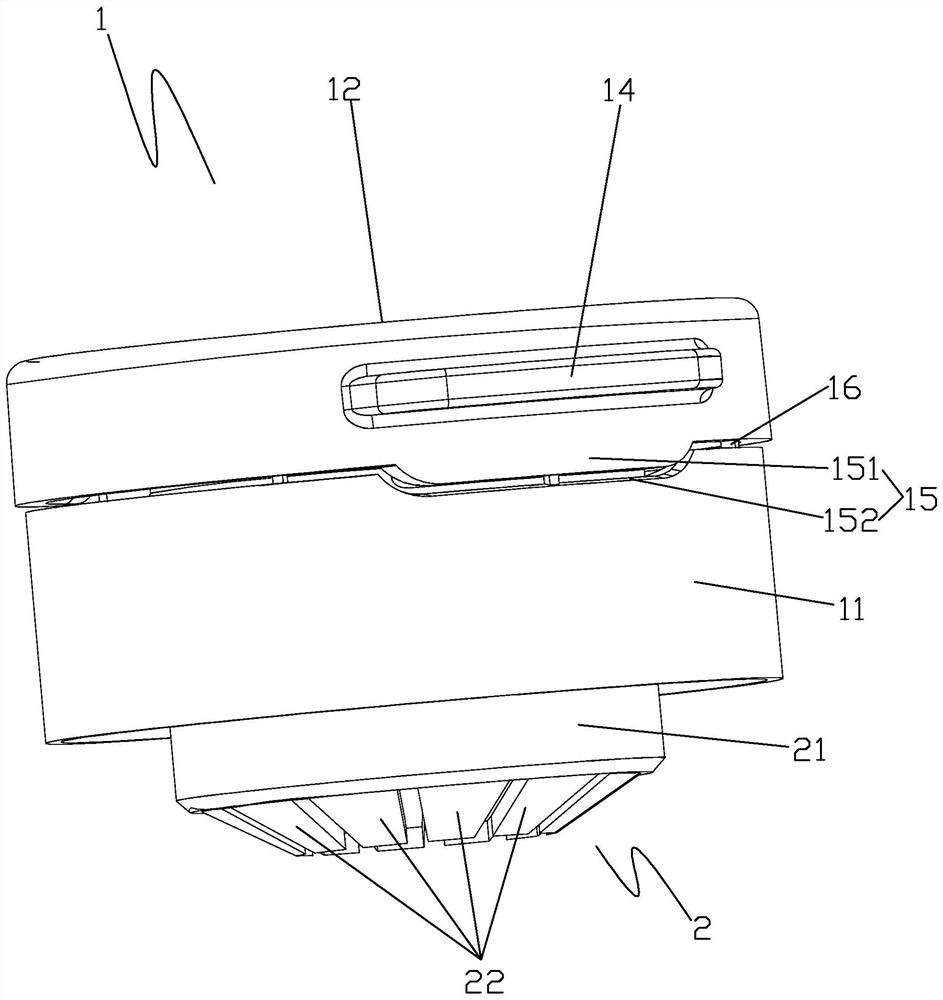

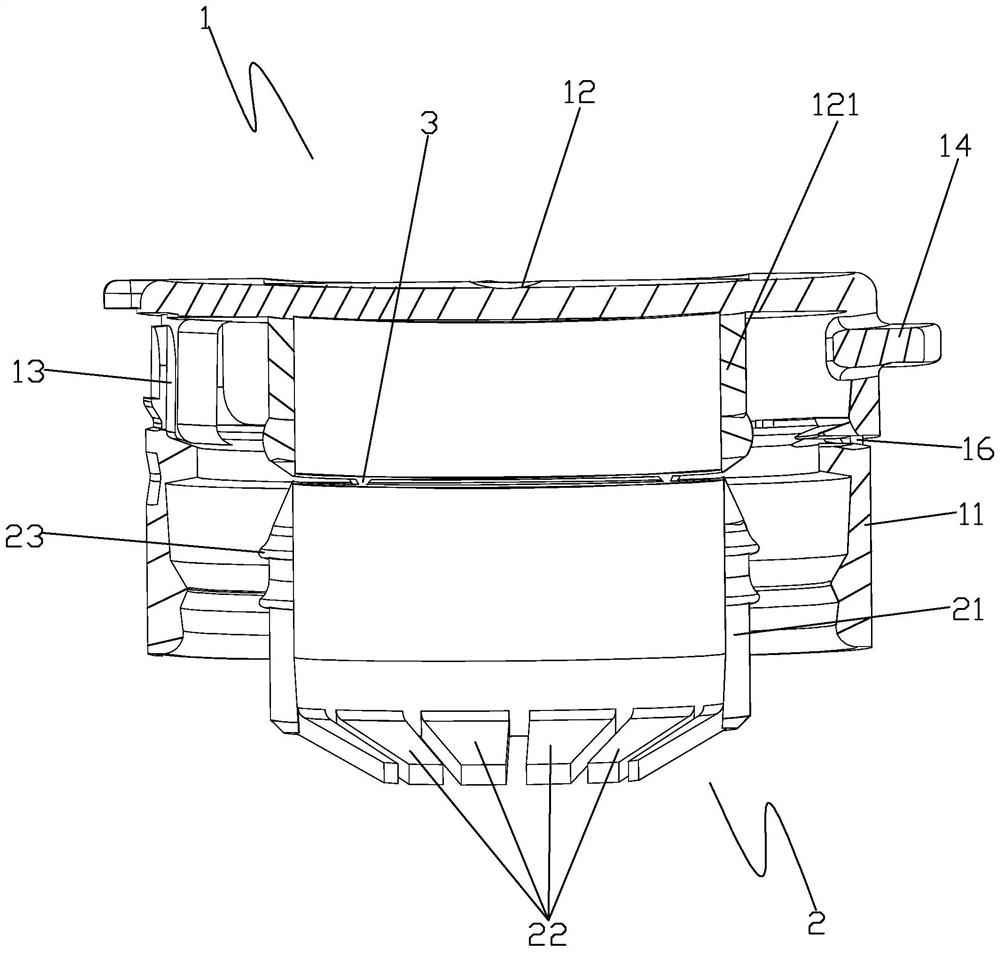

[0032] Attached below Figure 1-6 Embodiments of the present invention will be described in detail.

[0033] like Figure 1-6 As shown, the present invention is an integrated lid assembly, including a lid body 1 for connecting with the mouth of the container, and the lid body 1 is equipped with When the lid 1 opens the mouth of the container, the filtering and stabilizing assembly 2 can be separated from the lid 1 and stay in the mouth of the container. The filtering and stabilizing assembly 2 is integrated with the lid 1 through the breakable connecting part 3 Injection molded monolithic structure. When the container is filled with liquid and the cap assembly is connected to the mouth of the container for the first time, the staff first connects the cap body 1 to the mouth of the container, and at the same time inserts the filter stabilization assembly 2 into the mouth of the container; when the container is sold When used by the user, that is, when the user operates the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com