Method for improving infrared shading performance of aerogel heat-insulation composite material

A composite material and airgel technology, which is applied in the field of improving the infrared shading performance of airgel thermal insulation composite materials, can solve the problems of low extinction coefficient, achieve low radiation heat conduction, reduce surface tension, and excellent infrared radiation shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

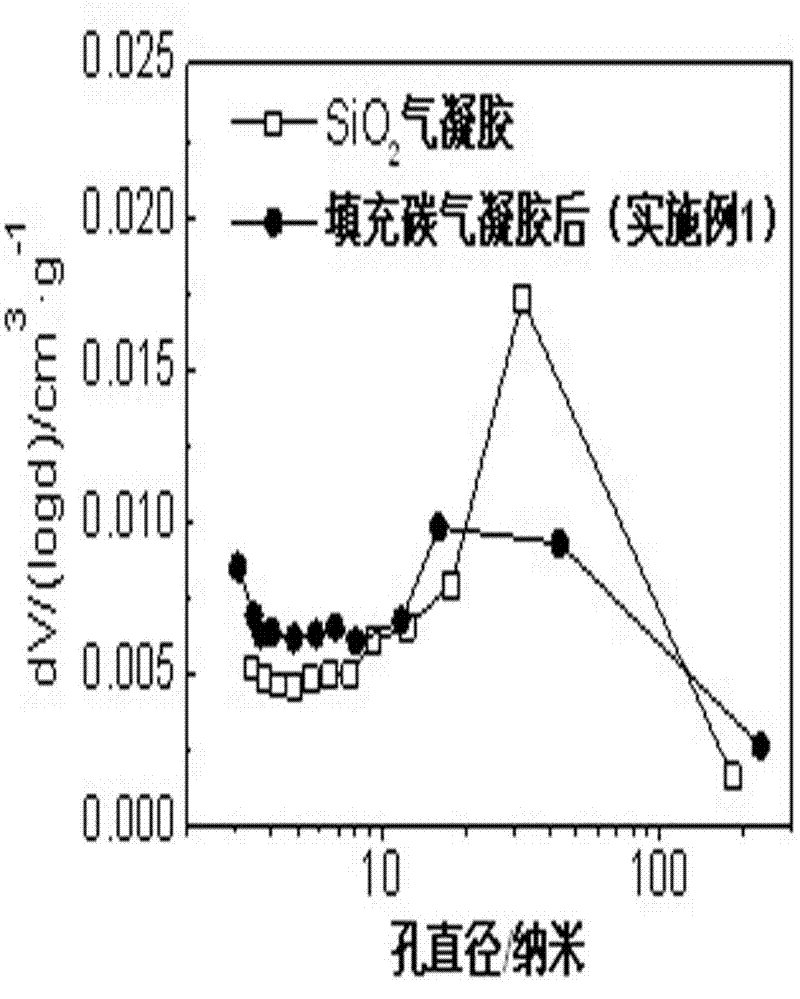

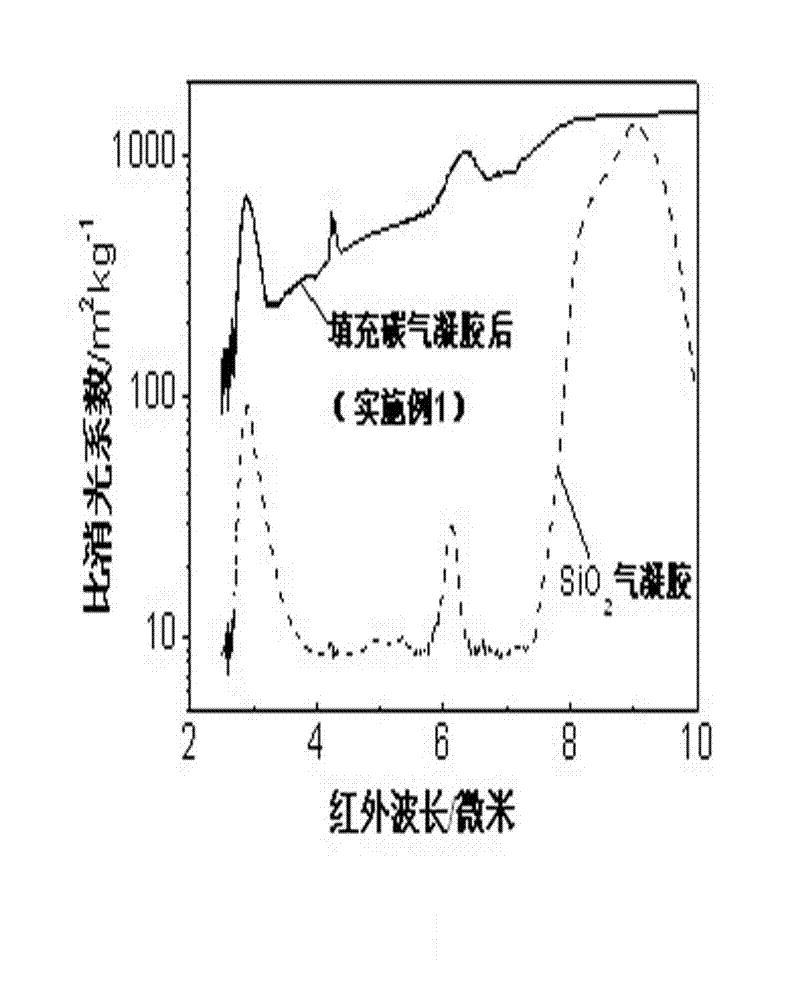

Embodiment 1

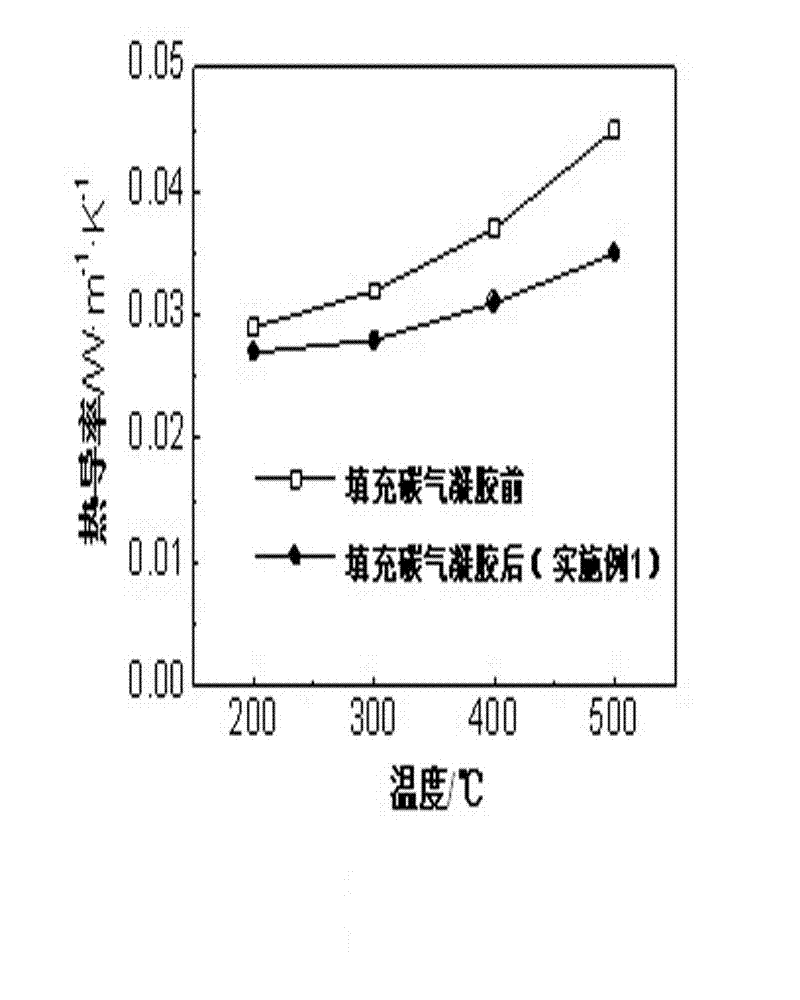

[0028]According to the molar ratio of raw materials resorcinol: furfural: hexamethylenetetramine: isopropanol = 1:2:0.02:25 to prepare a solution of about 1500mL, stir the mixed solution for 30 minutes, and then vacuum impregnate the density to 0.25g / cm 3 High silica fiber reinforced SiO 2 The airgel composite material is then placed in a 50°C water bath for 1 day, then the temperature of the water bath is raised to 75°C, and the temperature is kept constant for 5 days, and then the obtained resorcinol-furfural alcohol gel is filled with SiO 2 Put the airgel composite material into the autoclave, add petroleum ether at 60~90°C to the autoclave, the added volume is 0.2 times the volume of the autoclave, raise the temperature of the autoclave to 260°C at a heating rate of 3°C / min, and keep it warm. After 0.5 hours, release the supercritical petroleum ether in the autoclave completely within 1 hour at constant temperature, turn off the heating program, and after the autoclave i...

Embodiment 2

[0032] The matrix filled in this embodiment has a density of 0.18g / cm 3 Mullite fiber reinforced Al 2 o 3 -SiO 2 Airgel composite material, the preparation of resorcinol-furfural alcohol solution, impregnation, aging, supercritical drying and other processes are all the same as in Example 1 to obtain organic airgel filled mullite fiber reinforced Al 2 o 3 -SiO 2 Airgel composites. This material is put into cracking furnace, under the flow nitrogen of flow velocity 200 milliliters / minute, be heated up to 800 ℃ with heating rate 5 ℃ / minute, after 0.5 hours of insulation, stop heating, under the protection of flow nitrogen, furnace temperature drops to After room temperature, the samples were taken out to obtain carbon airgel filled mullite fiber reinforced Al 2 o 3 -SiO 2 Airgel composite material, material density 0.24g / cm 3 . The carbon airgel filled with high silica fiber reinforced SiO 2 The thermal conductivity of airgel composites in air, the results are as Fi...

Embodiment 3

[0034] The raw materials used in this example are the same as in Example 2, and the preparation, impregnation, aging, supercritical drying and other processes of the resorcinol-furfural alcohol solution are the same as in Example 1, and the organic airgel-filled mullite fiber is obtained. Reinforced Al 2 o 3 -SiO 2 After airgel composites. This material is put into cracking furnace, under the flow nitrogen of flow rate 200 milliliters / minute, be heated up to 1000 ℃ with heating rate 5 ℃ / minute, after keeping warm for 1 hour, stop heating, under the protection of flow nitrogen, furnace temperature drops to After room temperature, the samples were taken out to obtain carbon airgel filled mullite fiber reinforced Al 2 o 3 -SiO 2 Airgel composite material, material density 0.25g / cm 3 . The carbon airgel filled with high silica fiber reinforced SiO 2 The thermal conductivity of airgel composites in air, the results are as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com