Cement decorative composite board and its construction method

A composite board and composite floor technology, which is applied to floors, buildings, building structures, etc., can solve problems such as inability to be reused multiple times, inflexible floor disassembly and assembly, and single floor functions, so as to achieve flexible construction and disassembly, Long service life and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

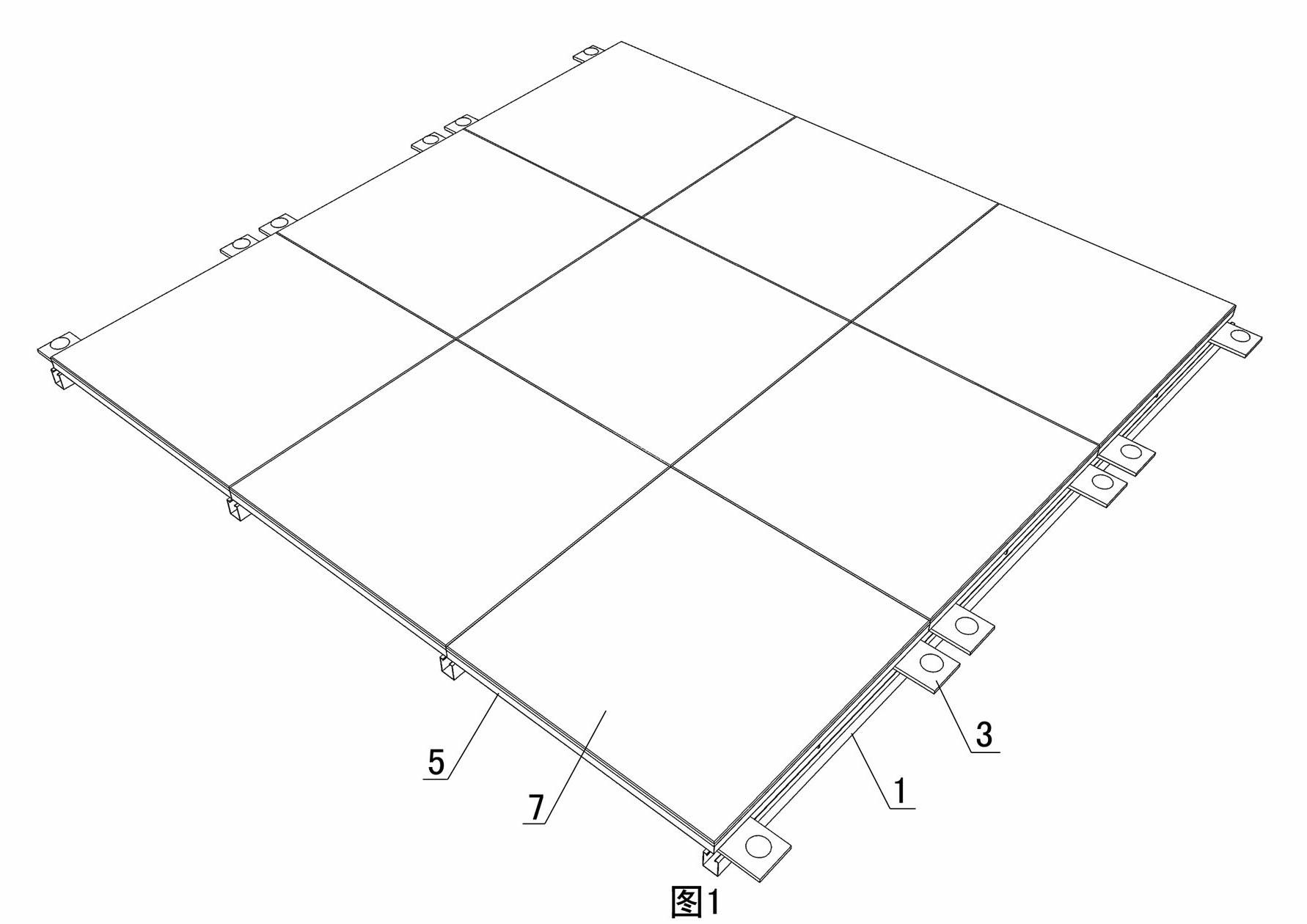

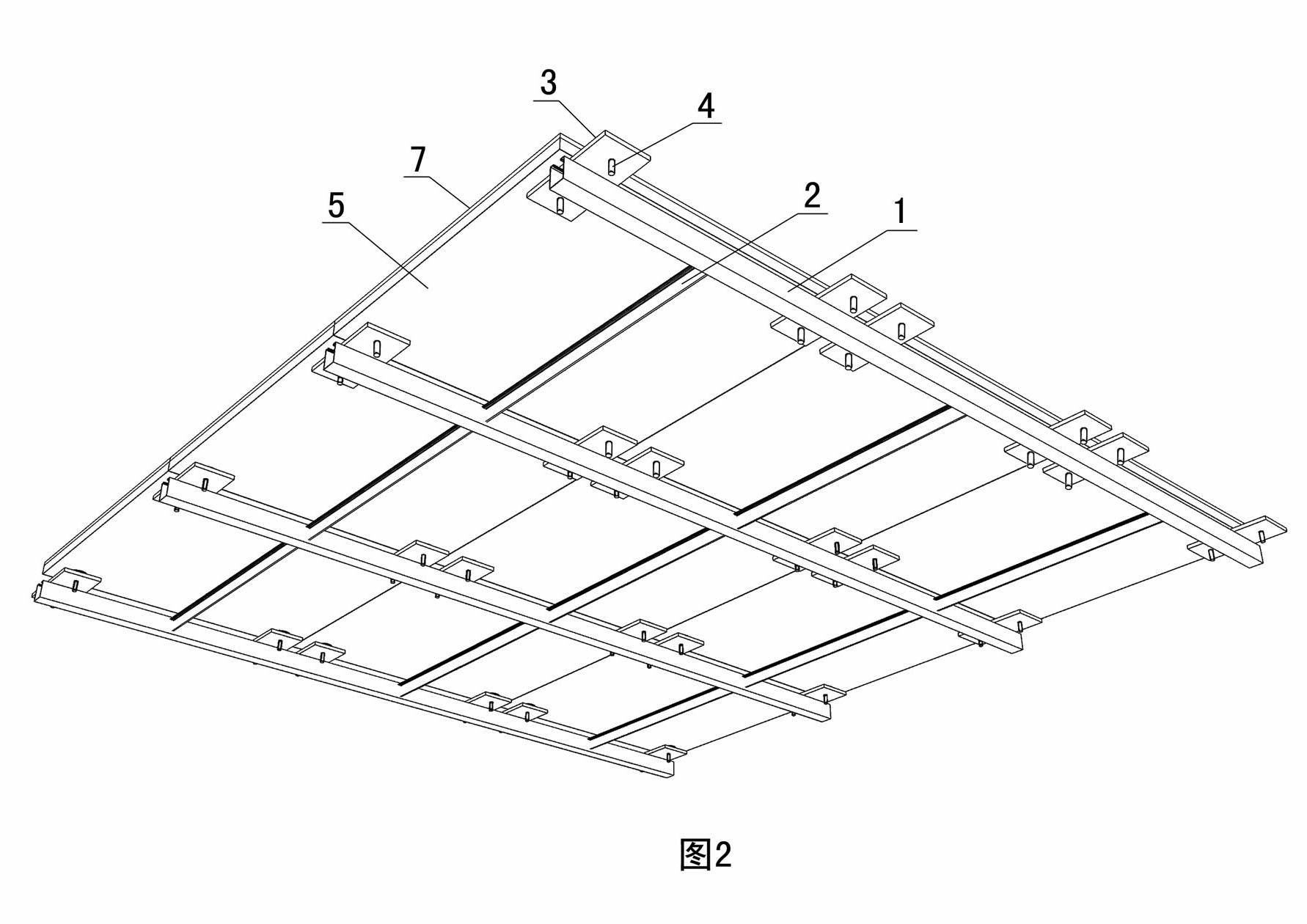

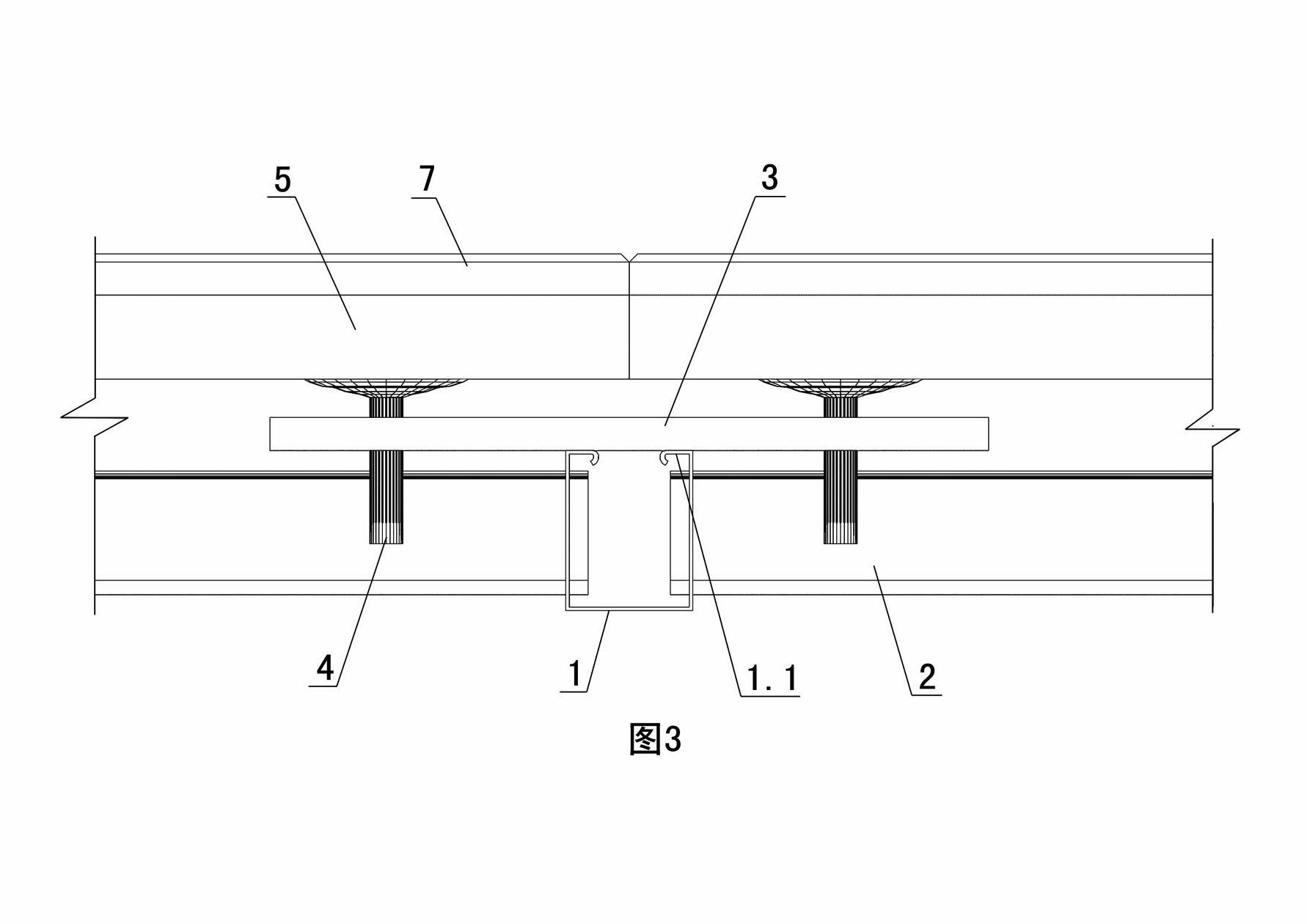

[0031] Examples see Figure 1-4 As shown, this cement decorative composite board includes a steel keel laid on the ground and a composite floor connected to the steel keel. The steel keel is composed of longitudinal main keels 1 distributed at intervals and placed on the ground and transverse auxiliary keels 2 located between two adjacent longitudinal main keels 1, wherein sockets are opened on both sides of the longitudinal main keels 1, and the transverse auxiliary keels The end of the keel 2 is inserted into the longitudinal main keel 1 through a socket; see image 3 , the longitudinal main keel 1 is in the shape of a groove (the shape of the groove is convenient for wiring), and the two upper sides of the longitudinal main keel 1 are bent inward to form a support edge 1.1 (the support edge can make the support gasket more stable on the longitudinal main keel. on the keel). The size of the longitudinal main keel 1 is 30*40*1.2mm, and the size of the transverse auxiliary k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com