furniture hinge

A hinge and furniture technology, applied in the field of furniture hinges, can solve the problems of small main force, bending of the piston rod, and smooth door closing, etc., and achieve the effects of small friction, long life and moderate strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

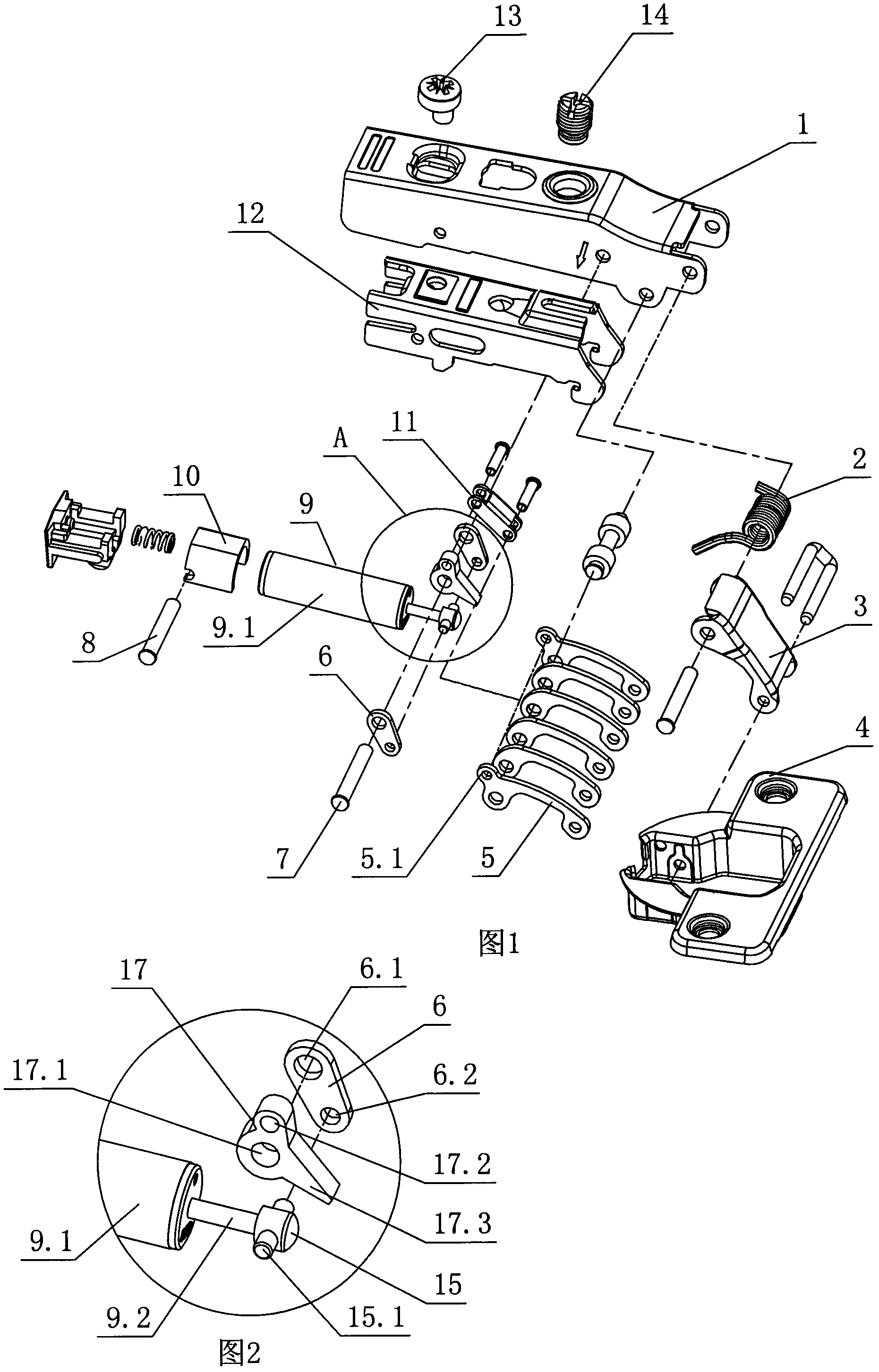

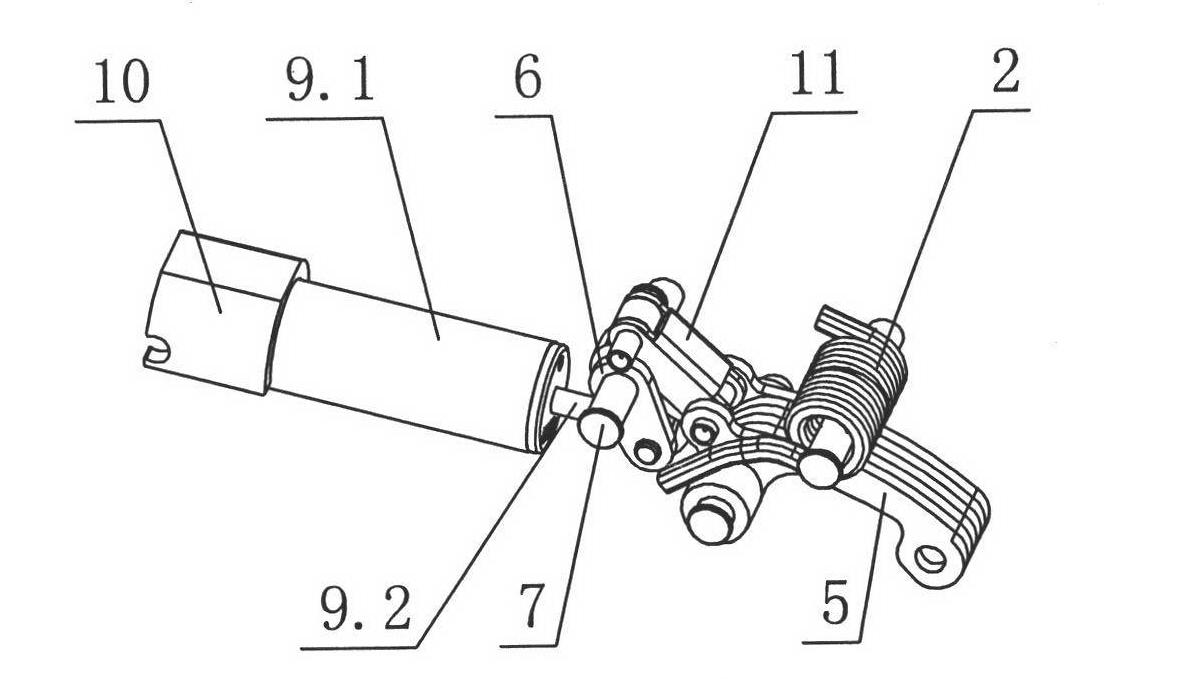

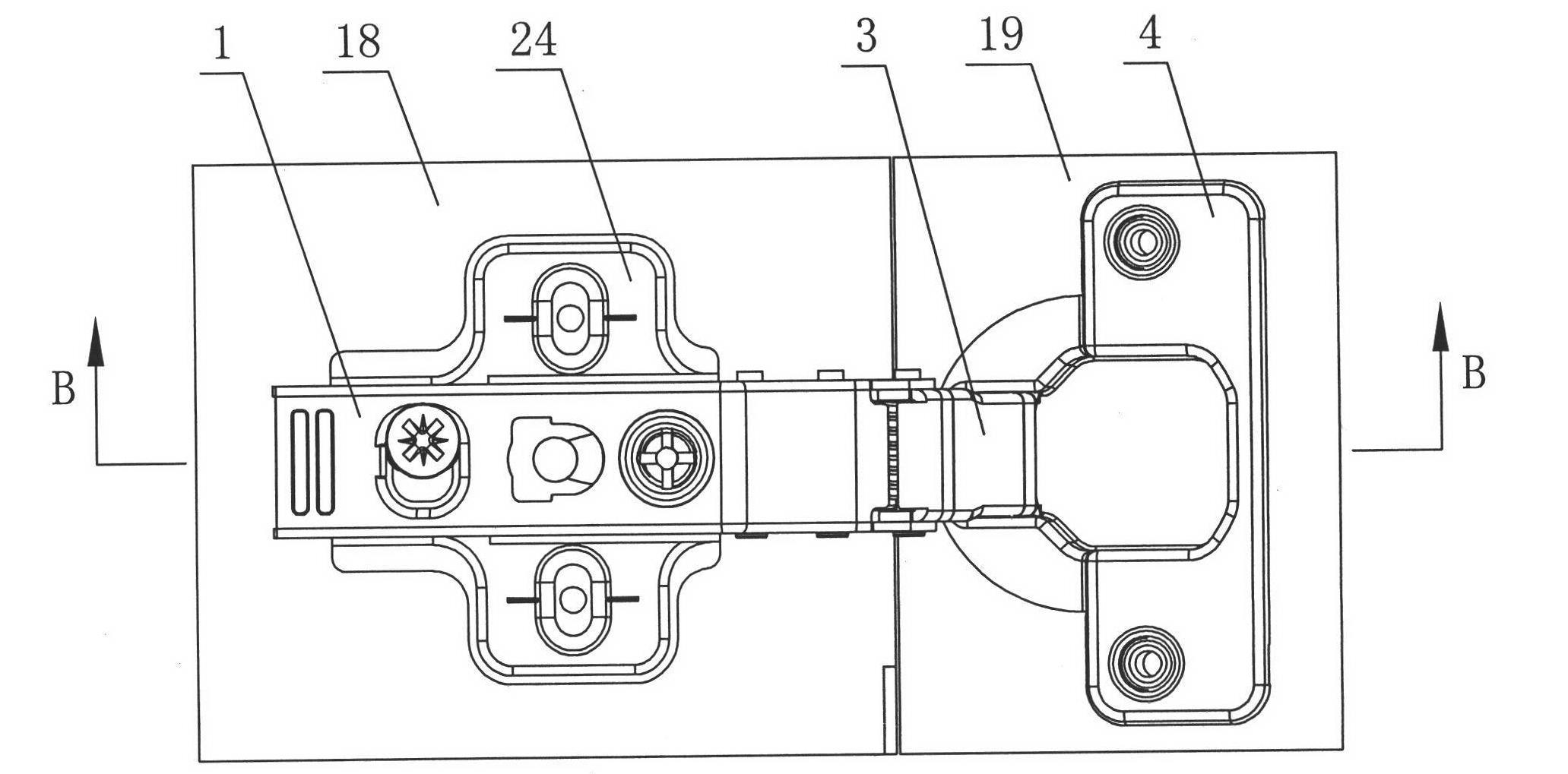

[0038] see Figure 1-Figure 7 , the furniture hinge includes a static member and a moving member that is in an active state relative to the static member during the hinge opening and closing process; the static member includes a connecting arm 1, and the connecting arm is provided with an automatic reset type damper that touches the moving member 9. One end of the automatic reset damper 9 is movably connected with the stationary member, and the other end is connected with the static member through a connecting piece; the connecting piece is respectively connected with the automatic reset damper and the static member in rotation.

[0039] The stationary component also includes a fixed arm 12, a fixed seat 24 and a component for connecting the stationary component and the moving component, which is preferably a pin 7; the fixed arm is connected to the inner side of the connecting arm 1 through the adjusting screw 14 and the eccentric wheel 13, and the connecting arm is fixed by ...

no. 2 example

[0051] see Figure 24 , the piston rod part 9.2' of the automatic reset damper points to the rear of the connecting arm, the end of the piston rod part is also provided with a hinge hole 9.4' to be rotatably connected with the connecting arm, and the cylinder part 9.1' is connected with the connecting arm through the connecting piece 6. The way in which the connecting piece 6 is connected with the cylinder body part 9.1' and the connecting arm may refer to the first embodiment. The structure of the connecting piece 6 can also refer to the various implementations introduced in the first embodiment.

[0052] The front end of the above-mentioned cylinder body part 9.1' can also be provided with a protrusion 9.5' to contact with the hinge moving member.

[0053] Other unmentioned parts are the same as those of the first embodiment.

no. 3 example

[0055] see Figure 25 , the transmission part of the contact block 77 and the inner rocker arm 25 are provided with intermeshing tooth patterns 77.1; Other unmentioned parts are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com