Intelligent regulation of vacuum system

A vacuum system and intelligent adjustment technology, applied in the field of low vacuum system, can solve the problems of wasting raw materials, unable to maintain, increase energy consumption, etc., and achieve the effects of cleaning and cleaning, improving working environment, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

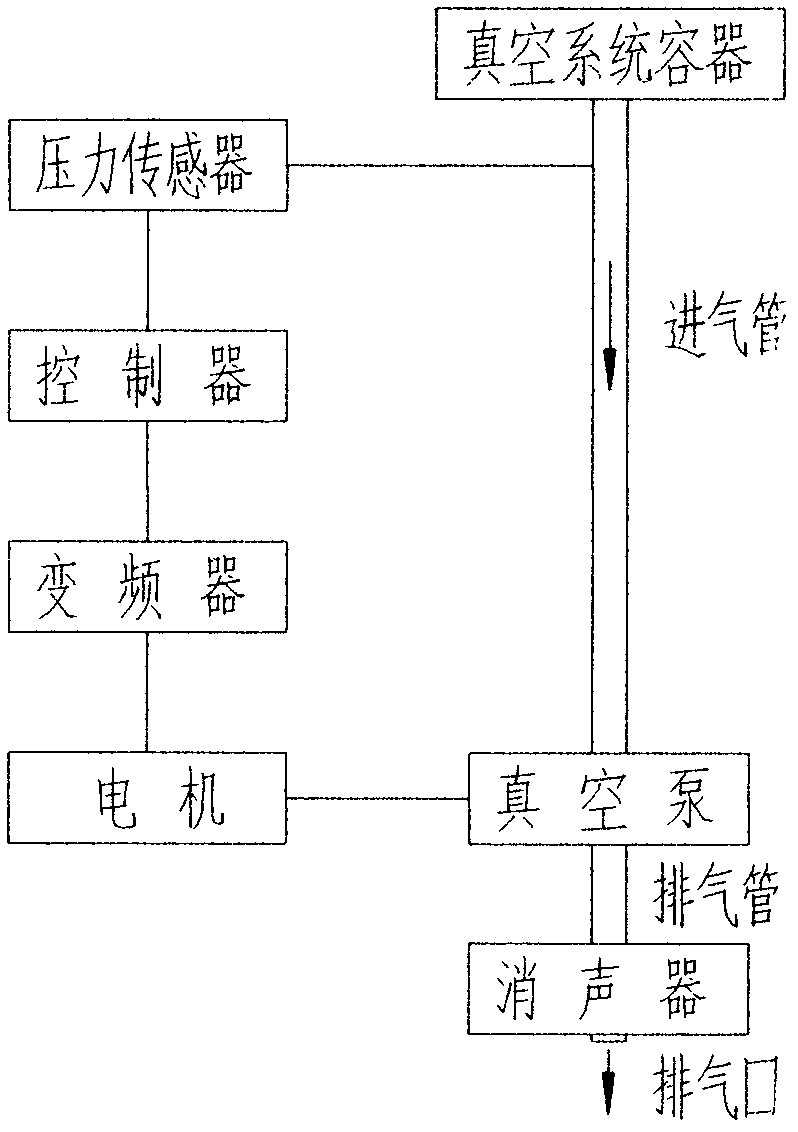

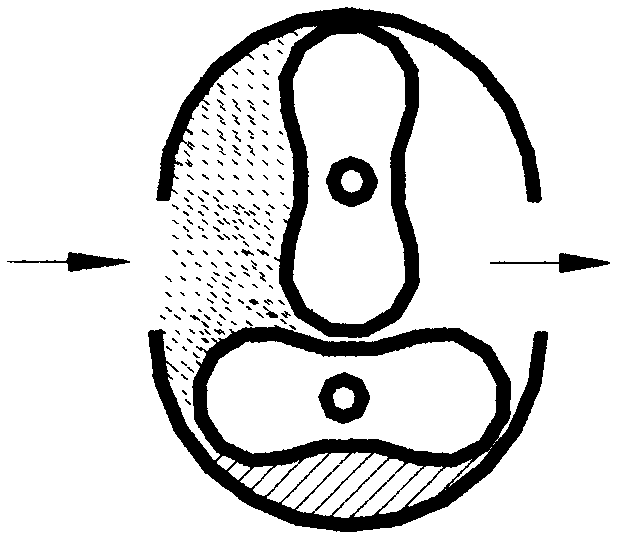

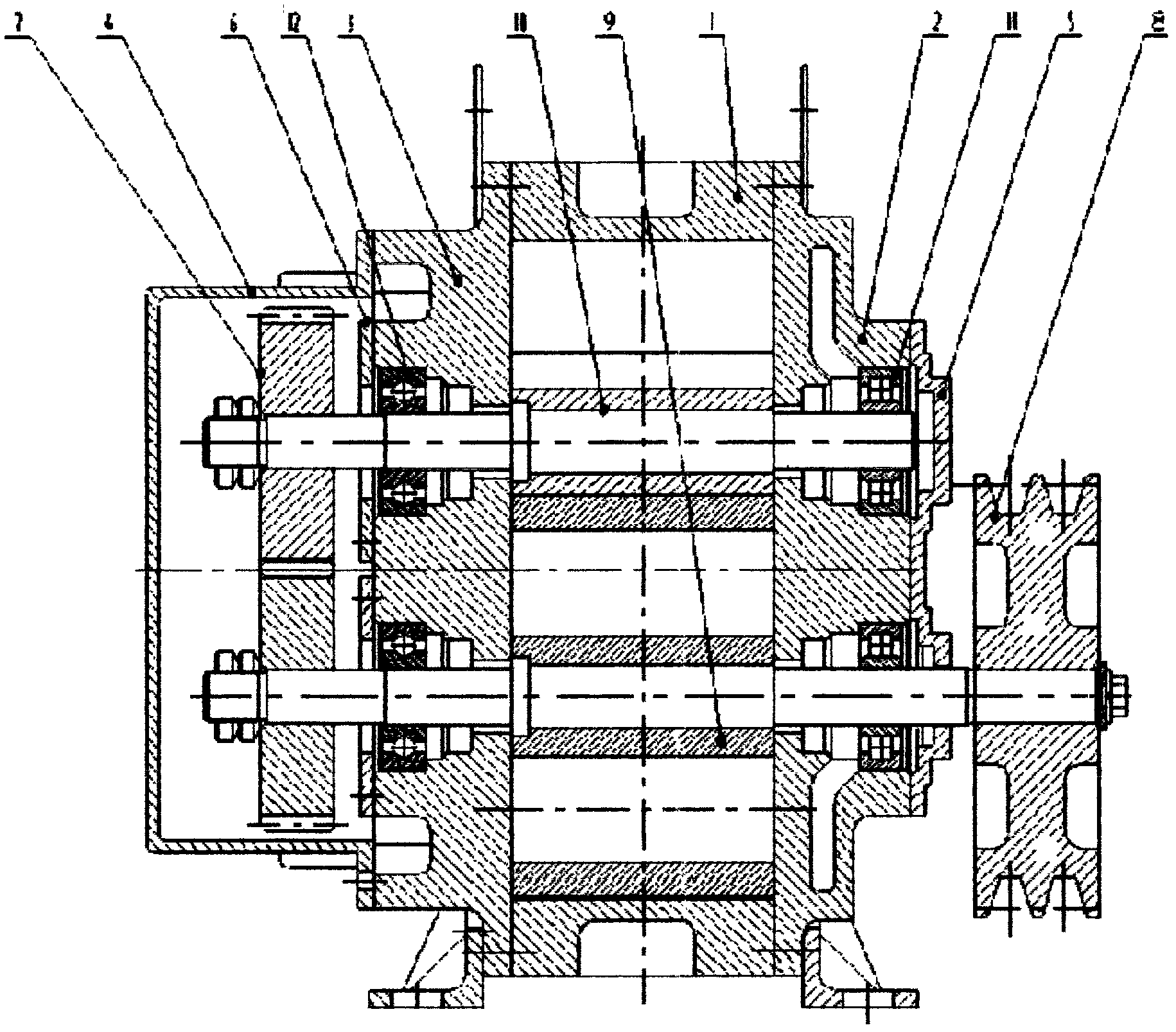

[0021] Embodiment 1: Intelligently adjust the vacuum system, the vacuum pump and the frequency conversion motor are connected through transmission components, the air inlet on the vacuum pump is connected to the system container through a pipeline, a pressure sensor is installed on the air inlet pipeline, the pressure sensor is electrically connected to the controller, and the controller It is connected with the frequency converter, and the frequency converter is electrically connected with the motor at the same time. When the pressure sensor detects the pressure in the intake pipe, it transmits the pressure to the controller. The controller controls the frequency of the frequency converter according to the pressure level. The frequency transmitted by the vacuum cleaner is used to adjust its own speed, change its own pumping capacity, and realize that the vacuum pressure in the vacuum system can be kept at a specified value and remain unchanged. The system control diagram of th...

Embodiment 2

[0031] Intelligently adjust the vacuum system, the vacuum pump is connected with the variable frequency motor through the transmission parts, the air inlet on the vacuum pump is connected with the system container through the pipeline, the pressure sensor is installed on the air inlet pipeline, the pressure sensor is electrically connected with the controller, and the controller is connected with the frequency converter At the same time, the frequency converter is electrically connected to the motor. When the pressure sensor detects the pressure in the intake pipe, it transmits the pressure to the controller. The controller controls the frequency of the frequency converter according to the pressure level. Frequency to adjust its own rotation speed, change its own pumping capacity, and realize that the vacuum pressure in the vacuum system can be kept at a specified value and remain unchanged. The system control diagram of the present invention is as follows figure 1 .

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com