A direct type led flat lamp

A LED flat lamp, direct-type technology, applied in the field of direct-type LED flat lamps, can solve the problems of increased production cost and production efficiency, increased overall lamp weight, and poor heat dissipation effect, so as to reduce production cost, increase heat dissipation area, and increase material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

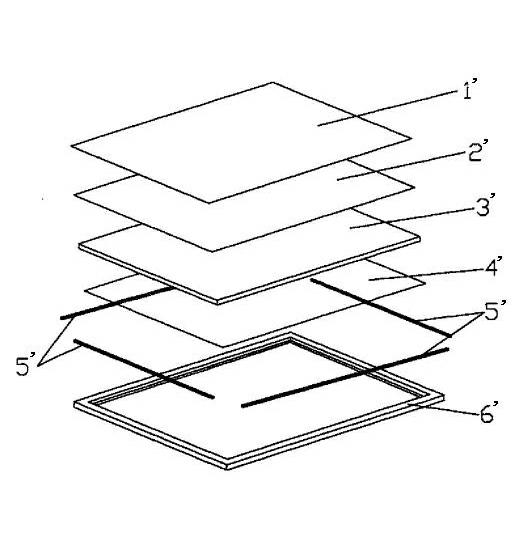

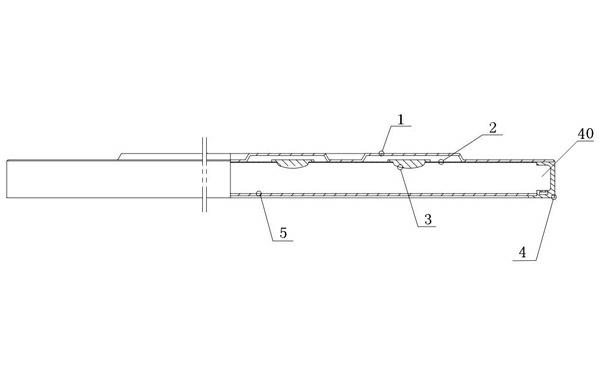

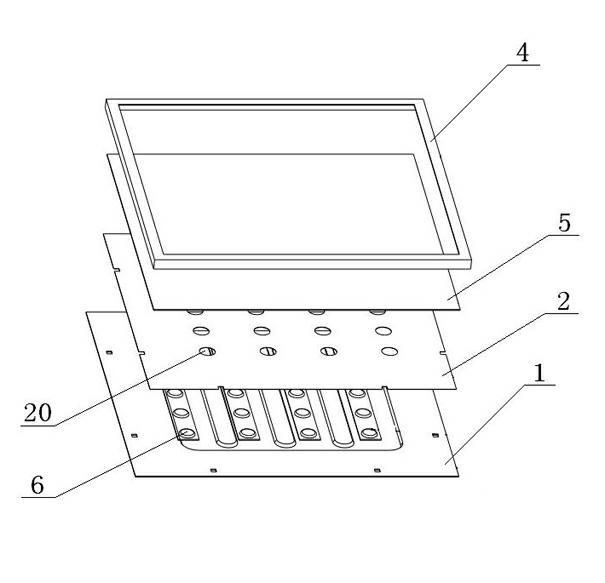

[0026] Such as figure 2 , image 3 As shown, a direct-lit LED flat lamp of this embodiment includes a hollow frame 4, a groove 40 is provided on the inner side of the frame 4, and a diffusion layer 5 and a reflective layer 2 are sequentially arranged in the frame 4 from the front to the back. With the substrate 1, a number of LEDs 3 are provided on the upper surface of the substrate 1 that is the side facing the front of the rectangular frame 4. Each LED 3 is covered with an LED lens 6, and the reflective layer 2 is provided with a number of small holes 20, small holes 20 is arranged corresponding to the LED3, and the LED3 coated with the LED lens 6 protrudes from the small hole 20 out of the reflective layer 2.

[0027] In this embodiment:

[0028] The frame 4 adopts a rectangular plastic frame. As an alternative, the frame material can be made of plastic or aluminum with flame retardant function or other flame-retardant lightweight materials. The frame shape can be square, rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com