Adaptive ultrasonic tracking and scanning array transducer

An ultrasonic transducer and self-adaptive tracking technology, which is applied in the direction of material analysis, instruments, and scientific instruments using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of not being able to adapt to the tracking and scanning of curved surface composite materials, and achieve improved detection efficiency, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

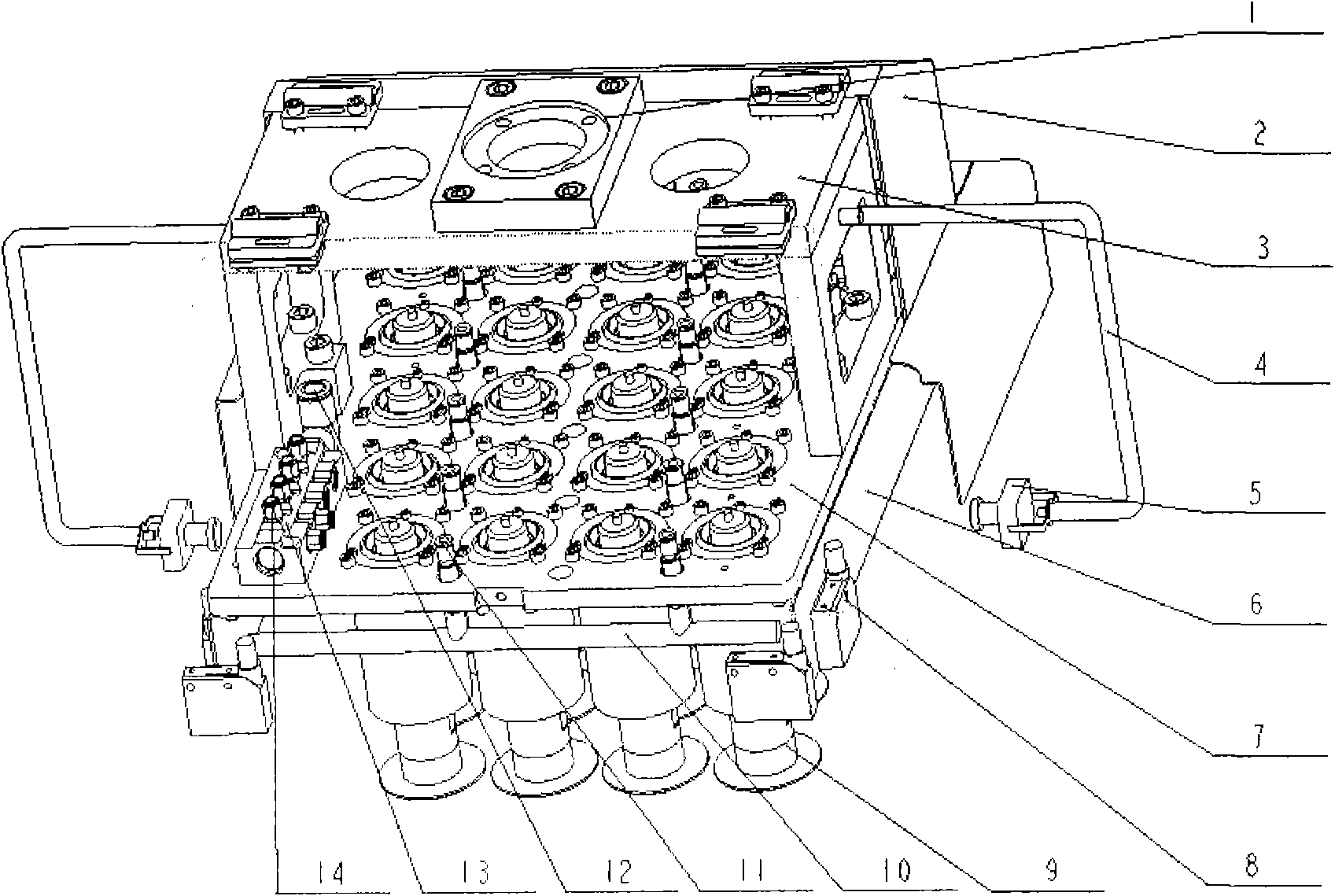

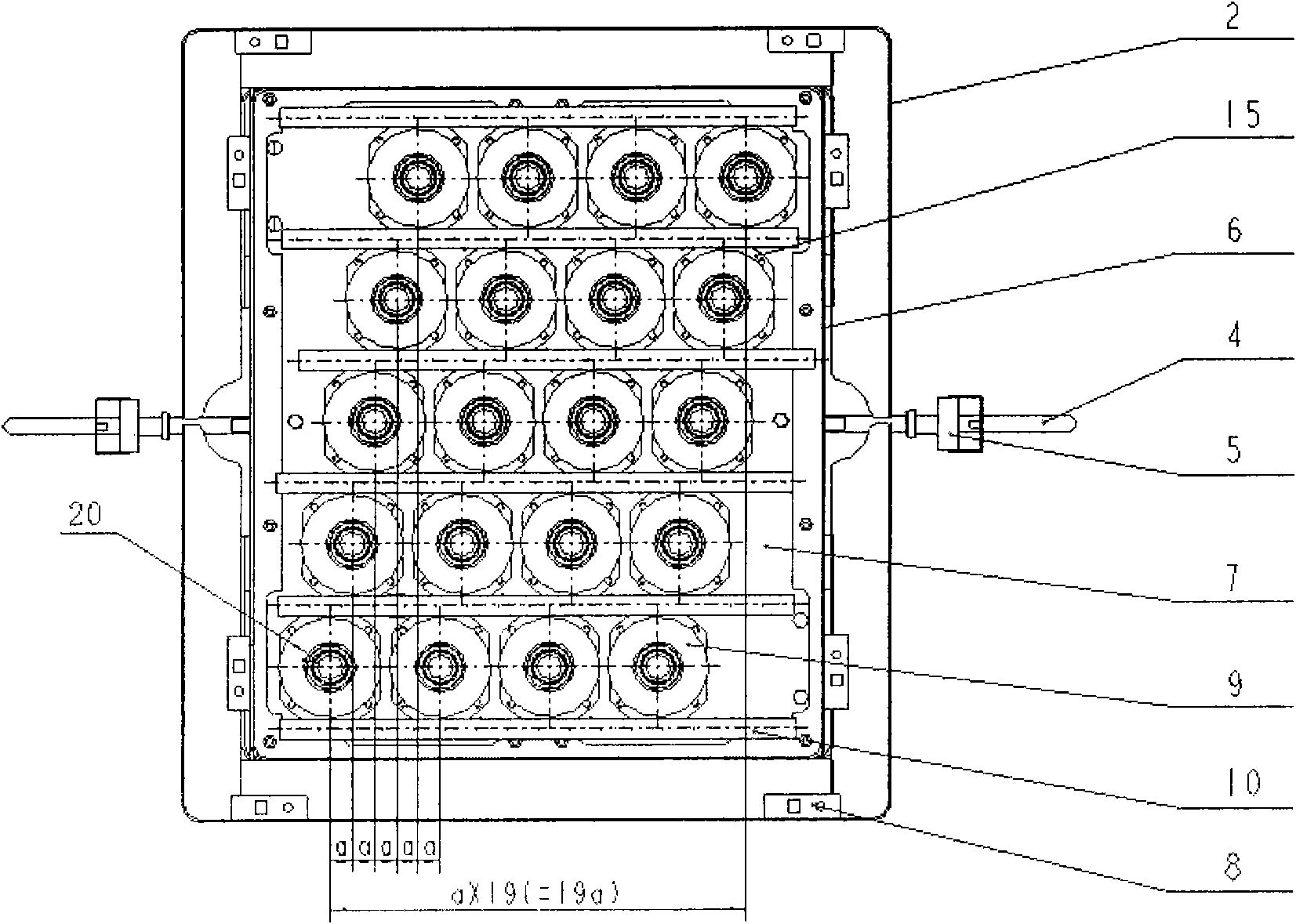

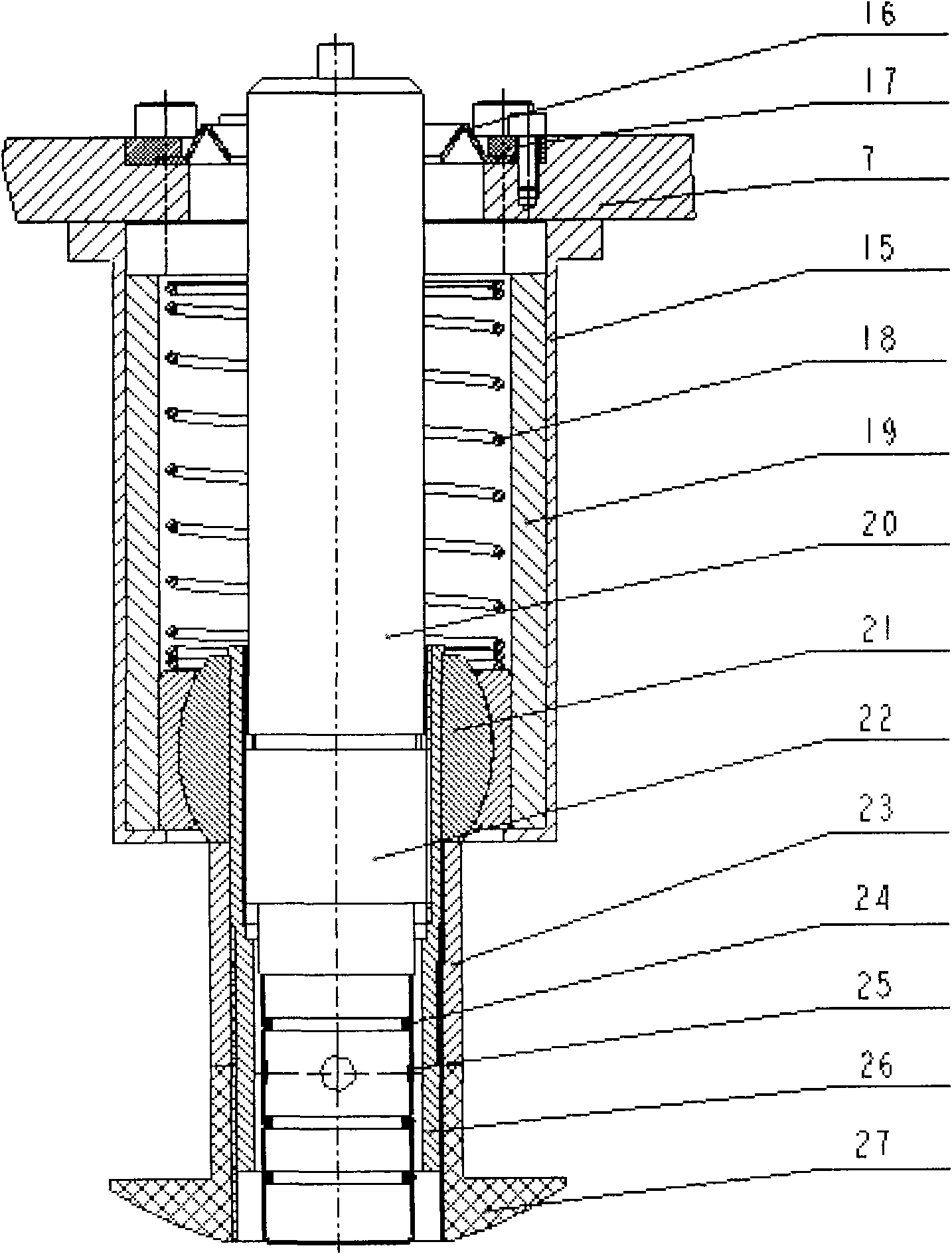

[0020] The transducer includes a probe shoe protective cover 2, a probe shoe bracket 3, a probe shoe base 7, an adaptive ultrasonic transducer unit 9, and a coupling waterway 10. The probe shoe protective cover 2 and the probe shoe bracket 3 are placed on the probe shoe base 7. On the top, the probe shoe protective cover 2 is connected to the probe shoe bracket 3, and the top of the probe shoe bracket 3 is provided with a connector 1 connected to an external ultrasonic automatic scanning system; the adaptive ultrasonic transducer unit 9 is configured according to a single adaptive ultrasonic transducer The area covered by the sound beam action area a of the detector unit 9 is arranged and installed on the probe shoe bracket 3, and the arrangement method is P r ×P c Array, where, r=1, 2, ... r, c = 1, 2, ... c, the Pth 11 The adaptive ultrasonic transducer unit 9 is placed on the lower left corner of the probe shoe base 7, the P 1cThe distance between the center of the adapti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com