Production method of lithium-ion power battery improving battery consistency

A power battery and production method technology, which is applied in the manufacture of battery electrodes, non-aqueous electrolyte batteries, and electrolyte batteries, can solve the problems of non-uniform consistency and differences in battery consistency, so as to improve consistency, prolong service life, Guarantee the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

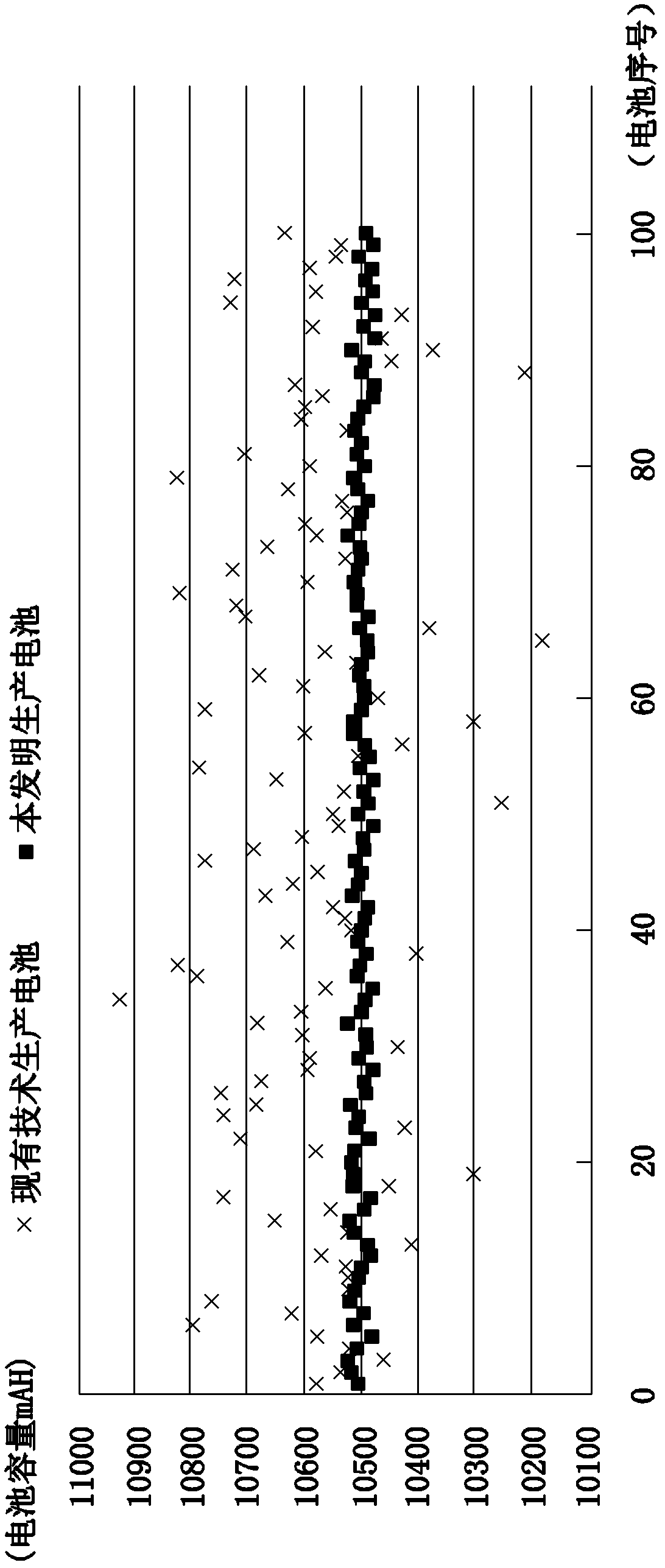

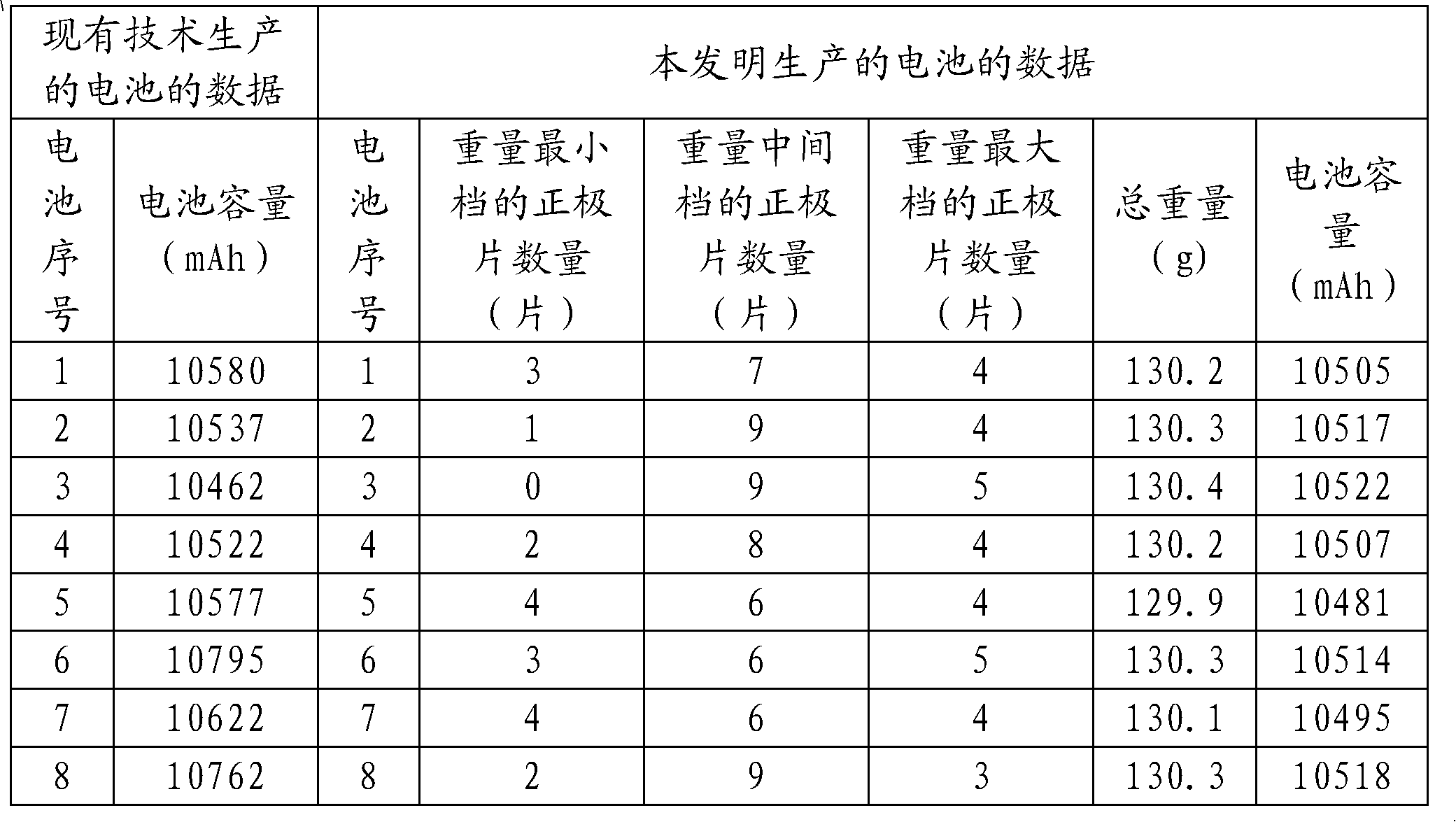

[0041] In the production method of the lithium-ion power battery that improves battery consistency, take the production of 100 10Ah batteries as an example.

[0042] Wherein, in step (3), the positive electrode sheet and the negative electrode sheet are divided into three grades, each including a minimum weight grade, an intermediate weight grade and a maximum weight grade. The weight range value corresponding to each grade of the positive plate: the smallest weight range: greater than or equal to 9.01g and less than or equal to 9.19g; the middle weight range: greater than or equal to 9.2g and less than or equal to 9.37g; the largest weight range: greater than or equal to 9.38g and less than or equal 9.55g.

[0043] In step (4), the total weight of the positive plates of 100 batteries is controlled respectively. The total number of positive electrodes in a single battery is 14, and the total weight range is 130±0.5g. In comparison, the total number of positive pole sheets of...

Embodiment 2

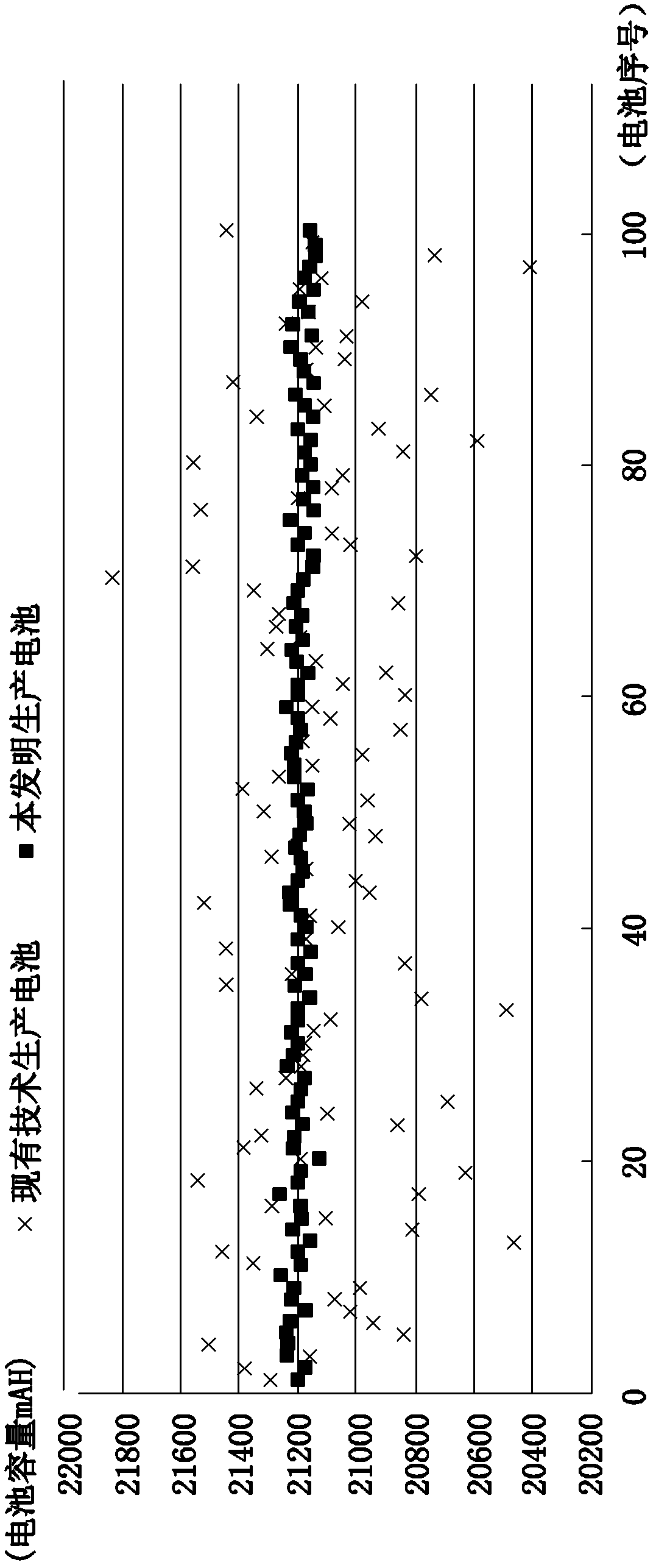

[0055] In the production method of the lithium-ion power battery that improves battery consistency, take the production of 100 20Ah batteries as an example.

[0056] Wherein, in step (3), the positive electrode sheet and the negative electrode sheet are divided into three grades, each including a minimum weight grade, an intermediate weight grade and a maximum weight grade. The weight range value corresponding to each grade of the positive plate: the smallest weight grade: greater than or equal to 13.34g and less than or equal to 13.62g; the middle weight grade: greater than or equal to 13.63g and less than or equal to 13.9g; 14.18g.

[0057] In step (4), the total weight of the positive plates of 100 batteries is controlled respectively. The total number of positive electrodes in a single battery is 19, and the total weight range is 261.5±0.5g. In comparison, the total number of positive pole sheets of the single battery produced in the prior art is the same as that of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com