High Current Carrying Connectors

An electric connector and current-carrying technology, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of restricting the large capacity of the electronic communication industry and unfavorable normal operation of the system, so as to improve production efficiency and safety performance, Simple structure, low temperature appreciation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

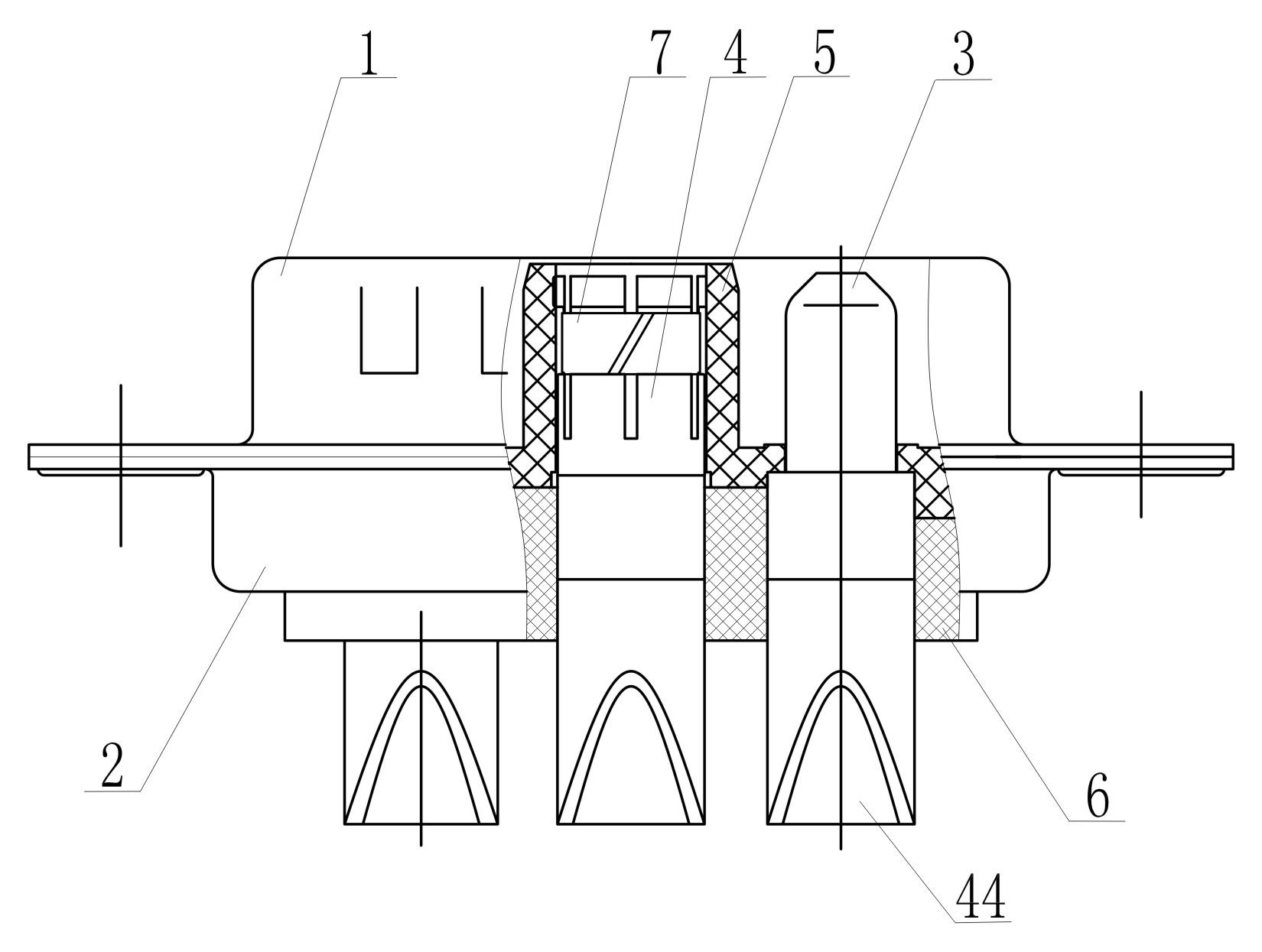

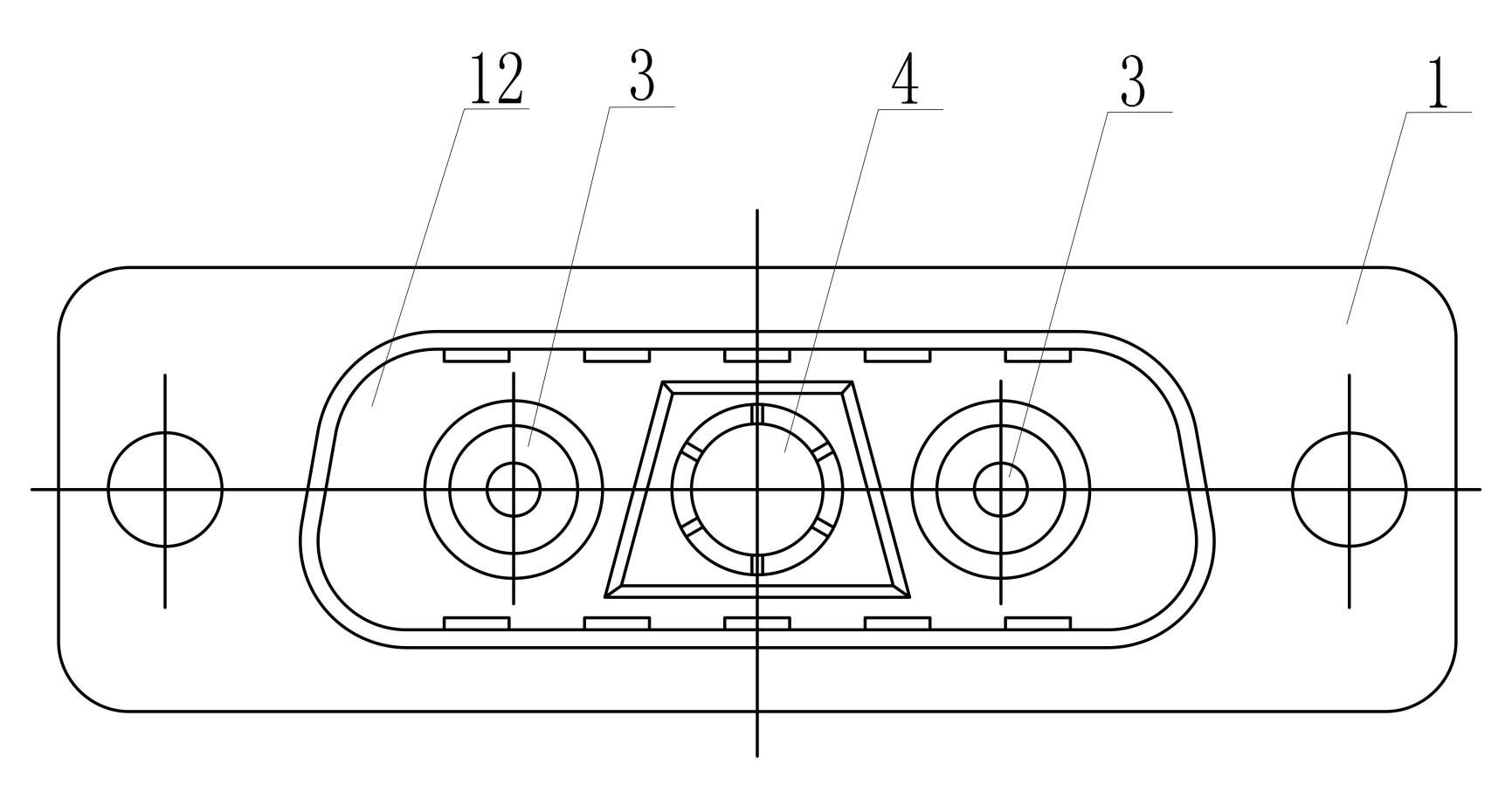

[0012] See attached figure 1 ~ attached figure 2 , the present invention consists of pins 3, sockets 4, upper end caps 1, and lower end caps 2 arranged on upper insulator 5 and lower insulator 6. 3 and the socket 4 are fixedly arranged on the upper and lower insulators 5 and 6, and the upper end cover 1 and the lower end cover 2 are fastened and sealed to form a rectangular electrical connector. After the upper end cover 1 and the lower end cover 2 are fastened, they are fastened by screws. The groove insertion hole 44 at one end of the pin 3 and the jack 4 is exposed outside the socket 12 of the lower end cover 2, and the plug 31 and the reed insertion hole 43 at the other end of the pin 3 and the jack 4 are exposed at the upper end. In the socket 12 of the cover 1.

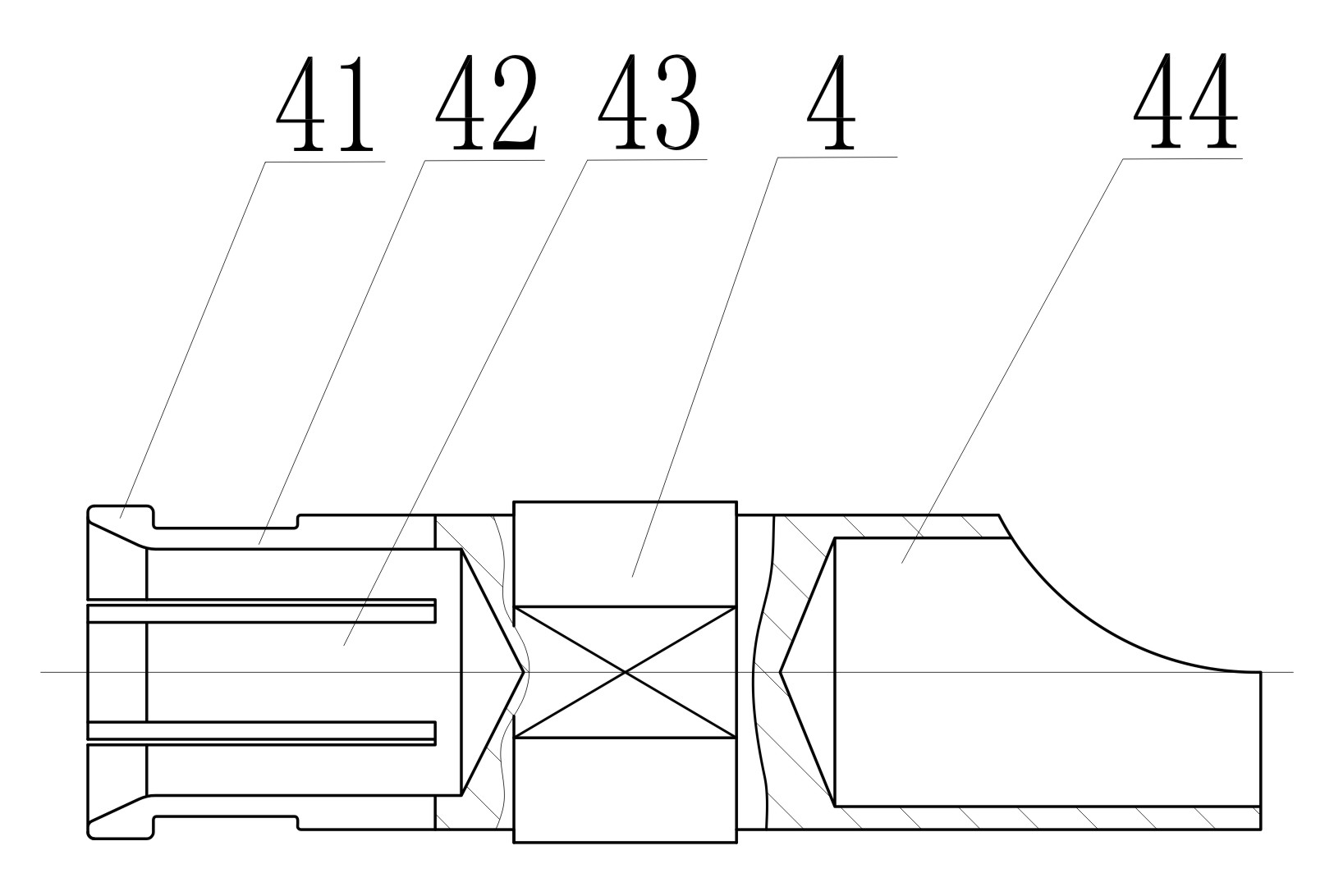

[0013] See attached image 3 , one end of the jack 4 is a reed insertion hole 43, and the other end is an electrical contact piece of a groove insertion hole 44. The reed insertion hole 43 is made of telluri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com