A combined aluminum profile cabinet frame

An aluminum profile and combined technology, applied in the direction of rack/frame structure, etc., can solve the problems of few elements on the profile section, large profile section size, and limited expansion functions, etc., to achieve cabinet space and cost reduction, stable load and support , Improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings of the description.

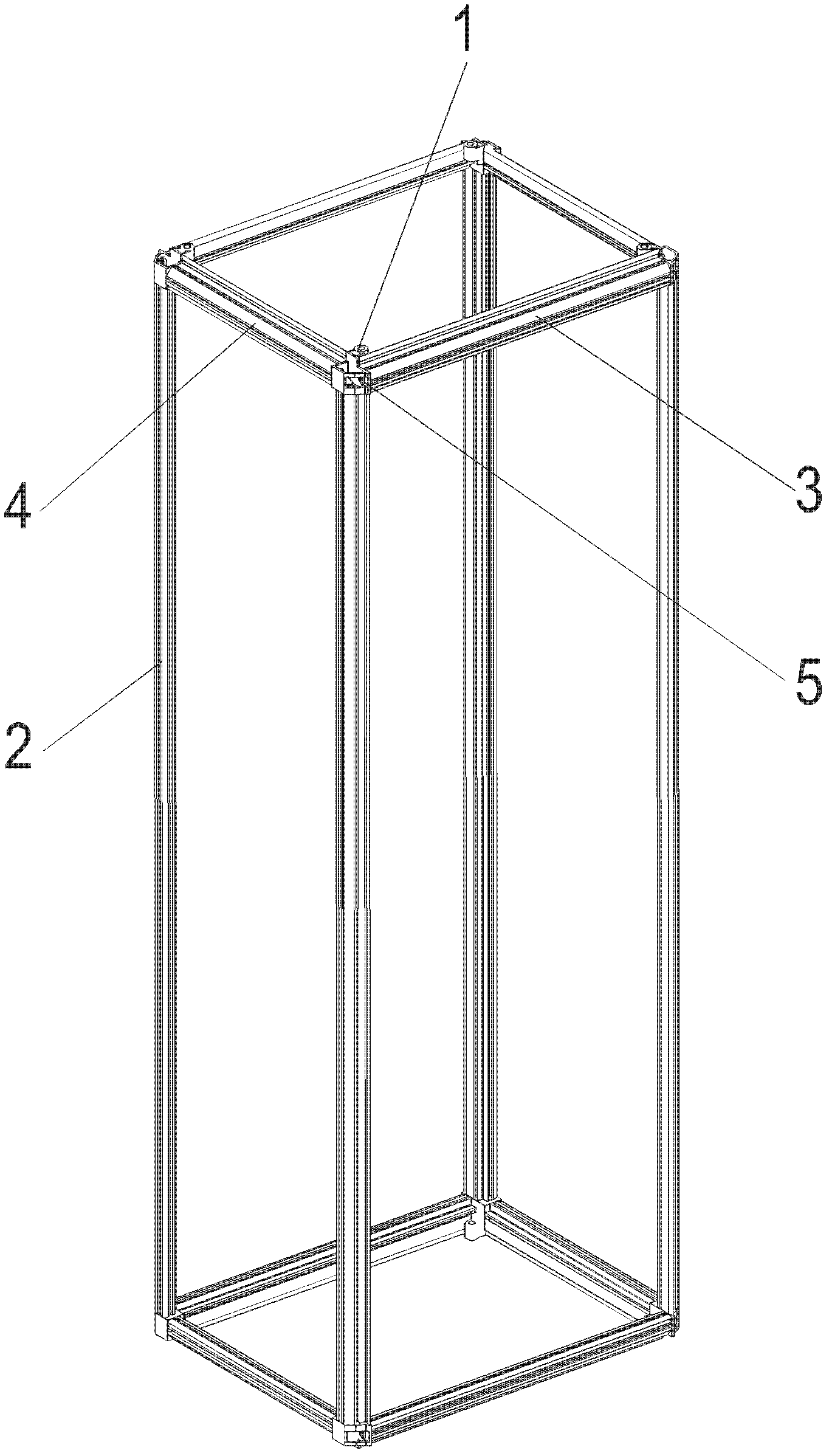

[0022] Such as figure 1 Shown is a perspective view of the frame structure of the cabinet, the frame is a cuboid structure consisting of four vertical profile beams 2, four horizontal profile beams 3, four longitudinal profile beams 4 and 8 corner joints 1 fastened to each other by bolts 5 Connection structure, by changing the length of profile beams, cabinet frames of different sizes and specifications can be combined. According to the requirements of the frame size, vertical profile beams 2, horizontal profile beams 3 and longitudinal profile beams 4 are respectively processed, and there are four profile beams in each direction.

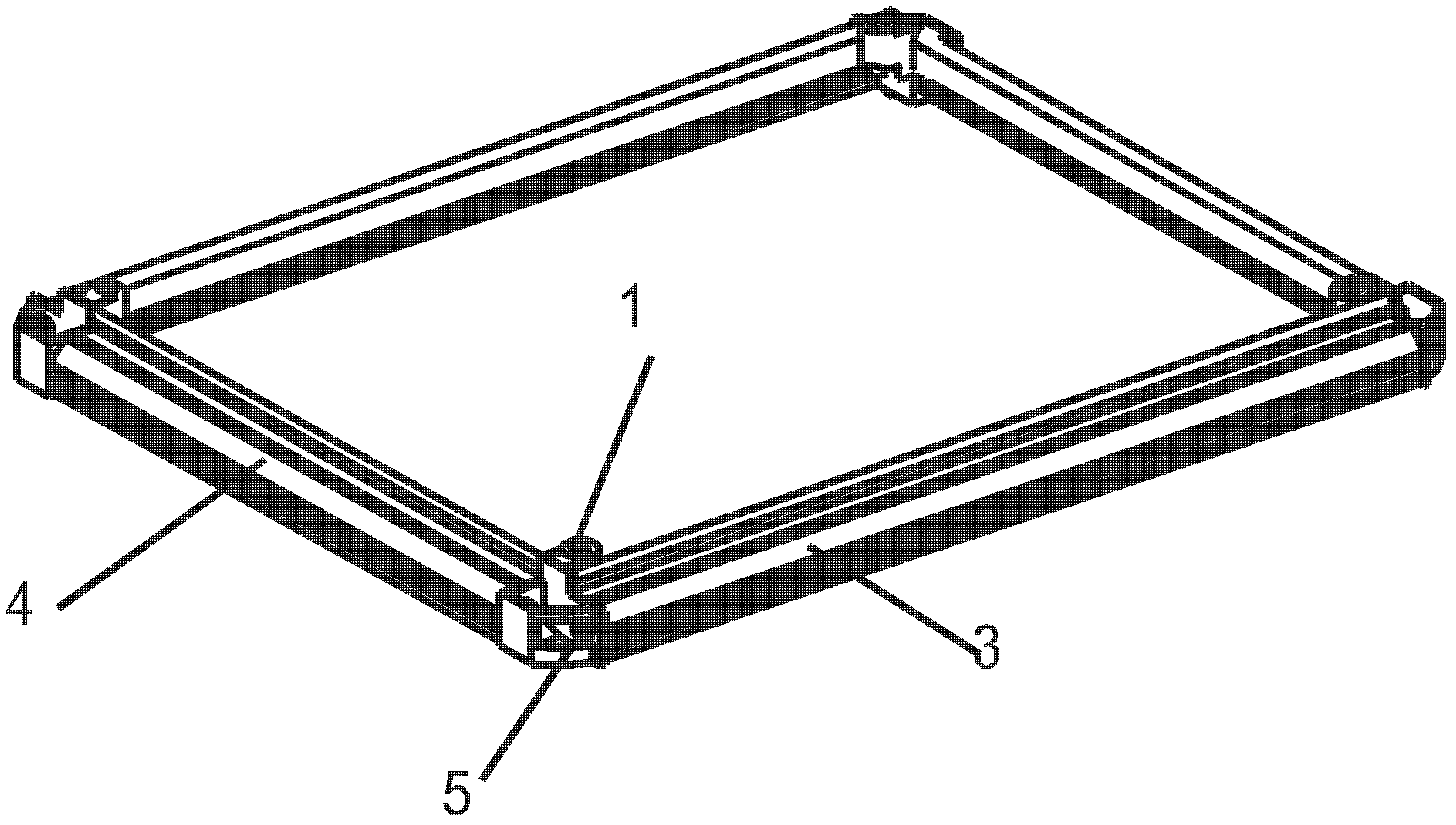

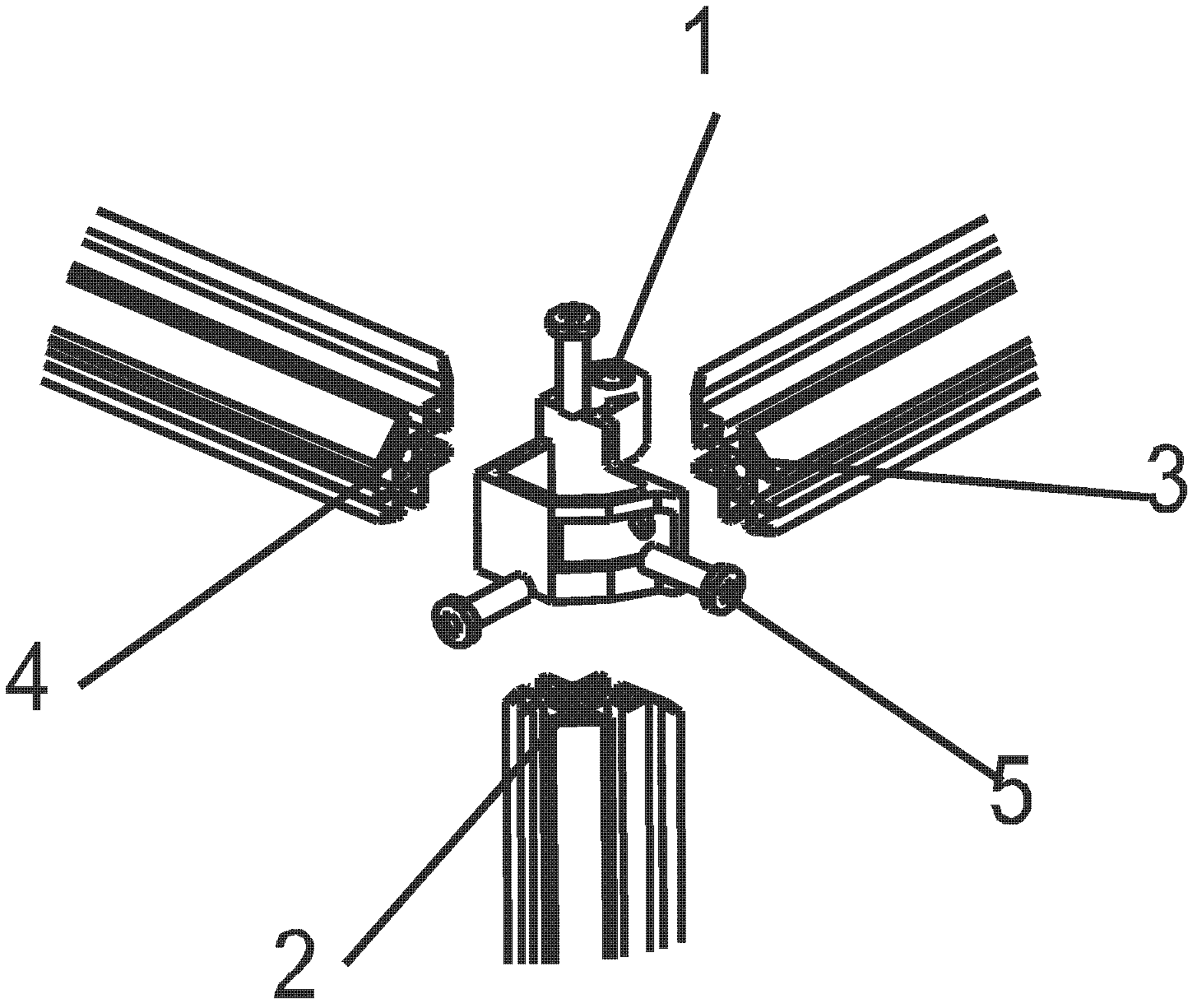

[0023] Such as figure 2 As shown, the upper and lower horizontal frames are first assembled, that is, the connection between the horizontal profile beam 3, the longitudinal profile beam 4 and the corner joint 1, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com