A kind of high-strength steel wire processing method

The technology of a high-strength steel wire and a processing method, which is applied in the field of roll rolling processing of high-strength steel wire, can solve the problems of high surface treatment quality requirements, poor plasticity of high-strength steel wire, low production operation rate, etc., and is beneficial to environmental protection. , good toughness and plasticity, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

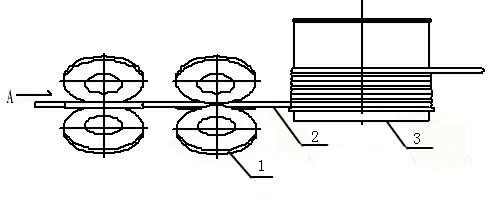

[0013] Embodiment of the present invention: the wire rod of SWRH82Bφ12.5mm is processed into a high-strength steel wire of φ5.05mm, combined with the attached figure 1 Be explained.

[0014] 1. Install and arrange the cemented carbide roll group

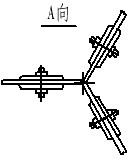

[0015] as attached figure 1 As shown in , two sets of cemented carbide rolls (1) are installed in a special stand, each set of rolls consists of three rolls, and the three rolls are evenly arranged in a star shape; the rolling surface of the rolls is an arc Shape, to ensure that the holes formed by the rolling surfaces of the three rolls are consistent with the required cross-sectional shape of the steel wire; arrange the two sets of rolls on the same straight line, so that the two holes formed by the two sets of rolls are aligned, and the two sets of rolls are aligned. The circumferential direction of the roll groups differs by 60 degrees, that is, if one set of rolls is arranged at 0, 120, and 240 degrees, the other set of rolls ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com