Anti-drip system for dump trucks transporting wet materials

A dump truck and anti-drip technology, which is applied in the direction of tilting and carrying vehicles, can solve the problems of damaging the environment, seeping and polluting the road, and the rear door 3 of the car and the car body 1 cannot be completely closed, etc., so as to improve trouble and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

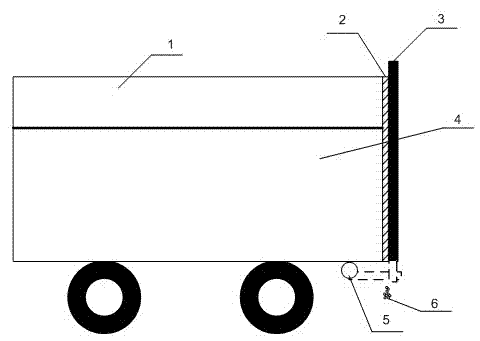

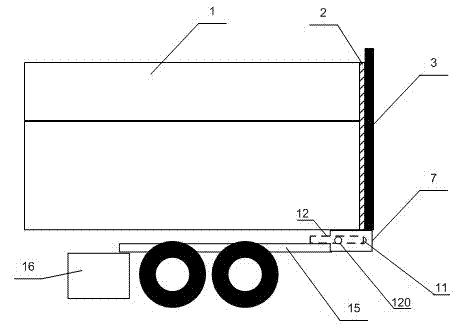

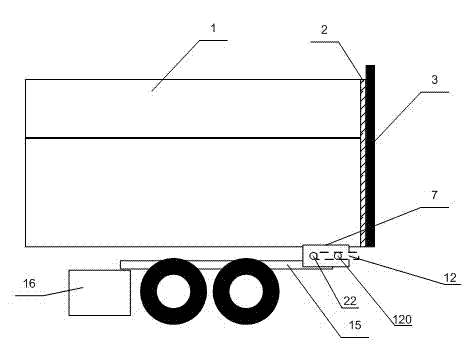

[0033] combined reference figure 2 Side view and image 3 The shown side view of the anti-drip system for transporting wet materials by dump truck in the state of loading and unloading shows that the anti-drip system for transporting wet materials by dump truck of the present invention is installed at the bottom of compartment 1 of the dump truck, compartment 1 and A sealing strip 2 is arranged between the compartment rear doors 3, wherein: the sump 7 is installed below the compartment rear door 3, and can be fixedly installed, such as welding to position the sump 7, and the sump 7 opens vertically upwards In order to make the sump 7 able to receive the waste liquid 6 dripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com