An axial flow water jet propulsion pump

A technology of water jet propulsion and axial flow, which is applied to axial flow pumps, propulsion components, ship propulsion, etc., and can solve the problems of long axial dimension, high manufacturing cost, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

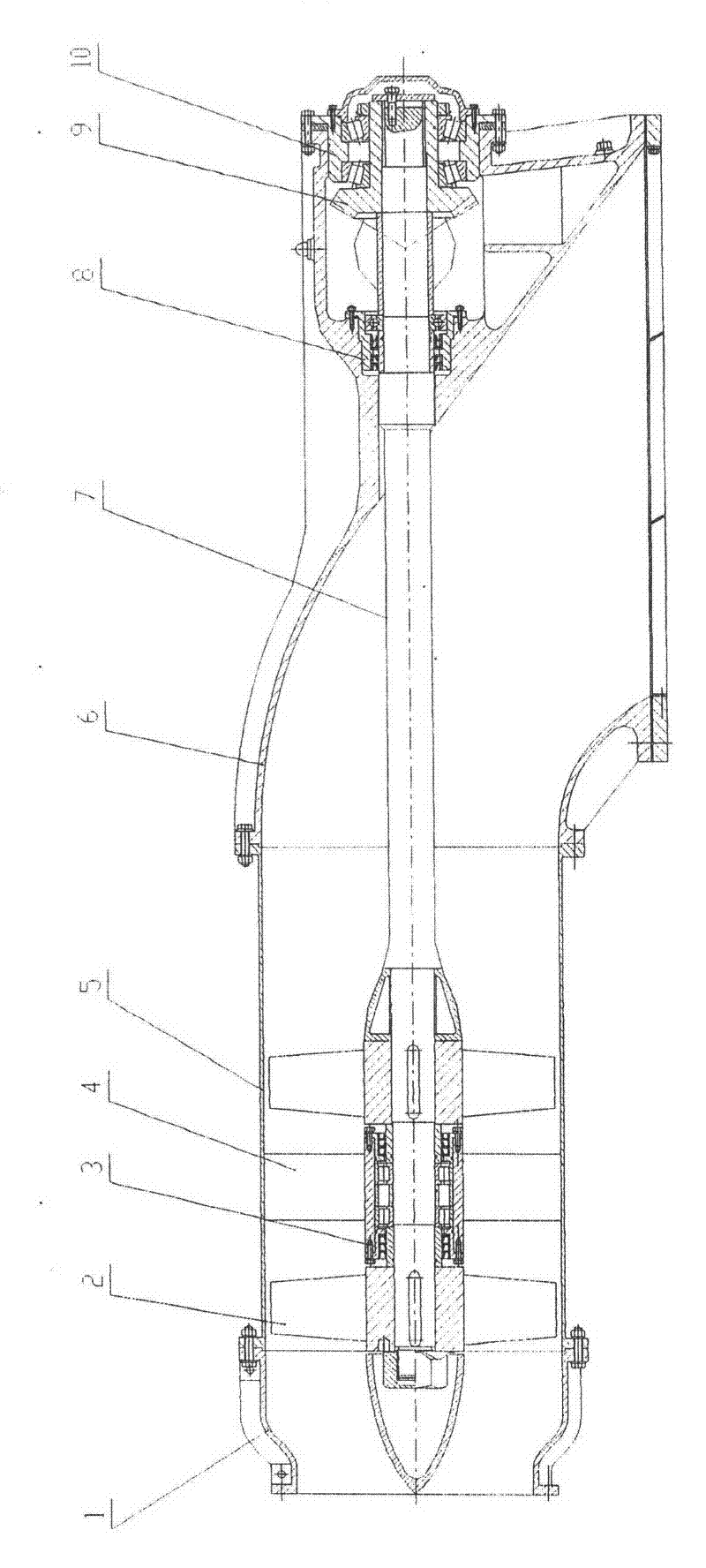

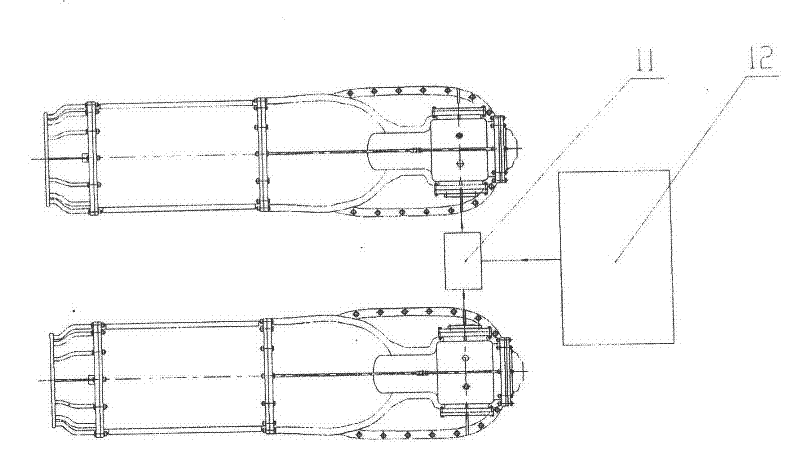

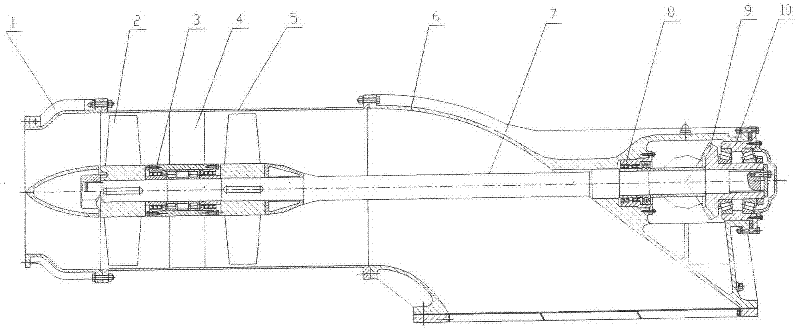

[0011] Such as figure 1 As shown, the axial flow water jet propulsion pump of the present invention includes a pump body, which contains a cylindrical middle section 5, and the front end and rear end of the cylindrical middle section 5 are respectively connected with a rectification nozzle 1 and an inlet elbow 6 , The inner bearing seat 3 is arranged in the cylindrical middle section 5 . The inner bearing seat 3 is coaxial with the cylindrical middle section 5, and three guide vanes 4 are arranged between the inner wall of the inner bearing seat 3 and the inner wall of the cylindrical middle section 5, and the two ends of the three guide vanes 4 are connected with the inner bearing seat respectively. 3. The outer ring and the inner wall of the cylindrical middle section 5 of the pump body are fixed together. The pump body is provided with a pump shaft 7, the front end of the pump shaft 7 passes through the inner bearing seat 3 and stretches out before the inner bearing seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com