A paper-plastic packaging machine

A packaging machine and paper-plastic technology, applied in the field of improved inventions, can solve problems such as cumulative errors, damage to cutting molds, and increased mold costs for packaging companies, achieving the effect of highlighting substantial features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

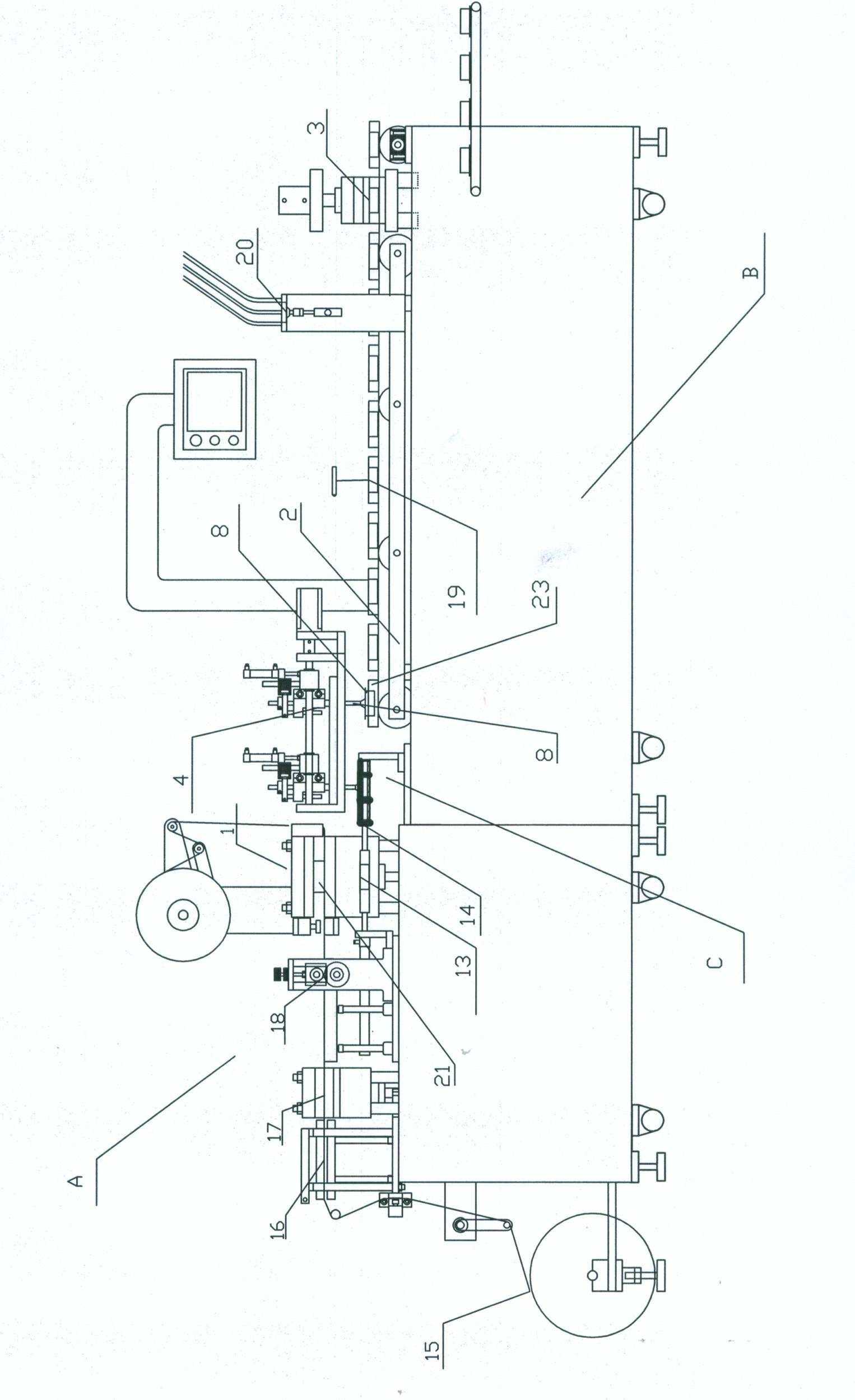

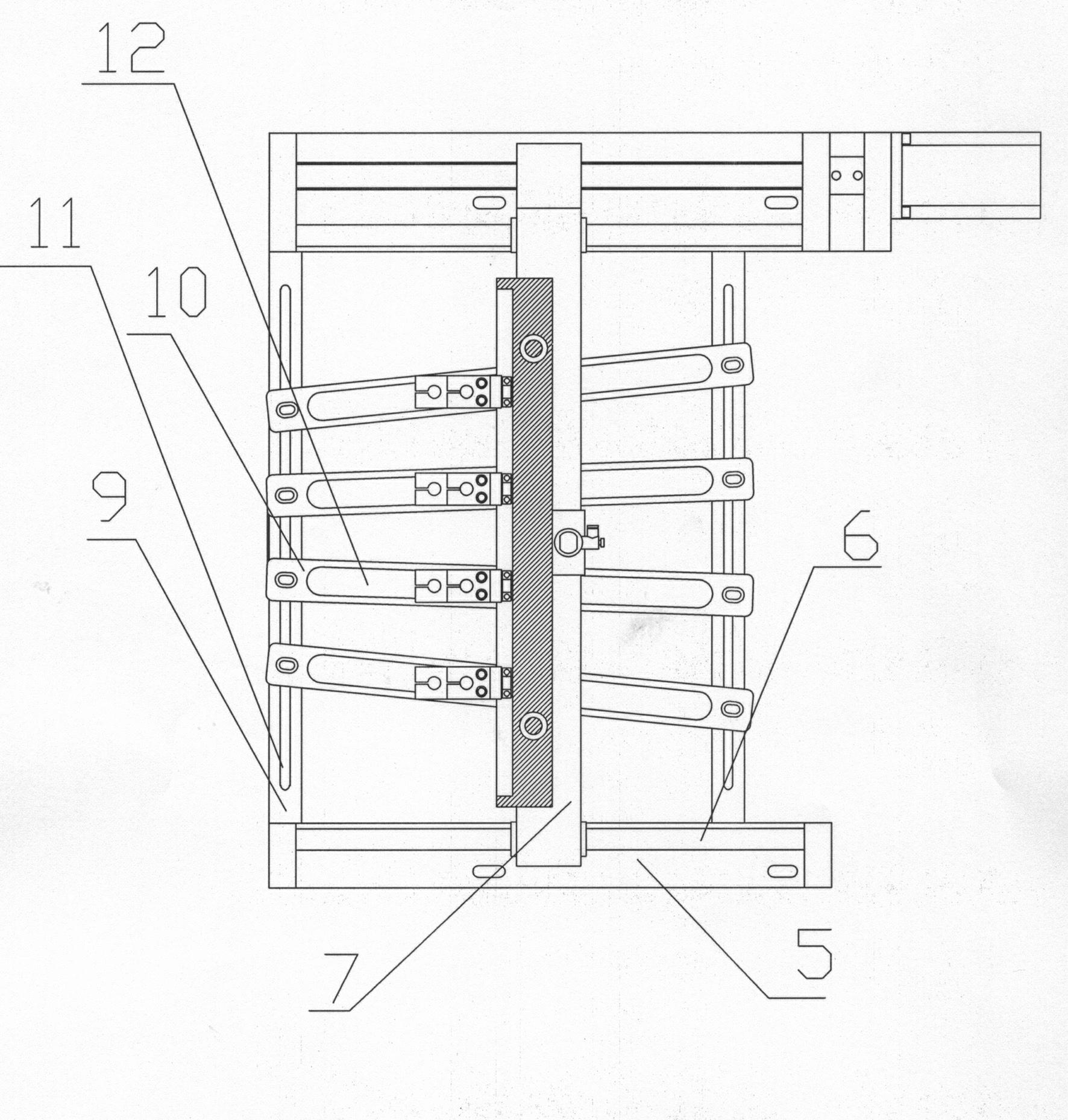

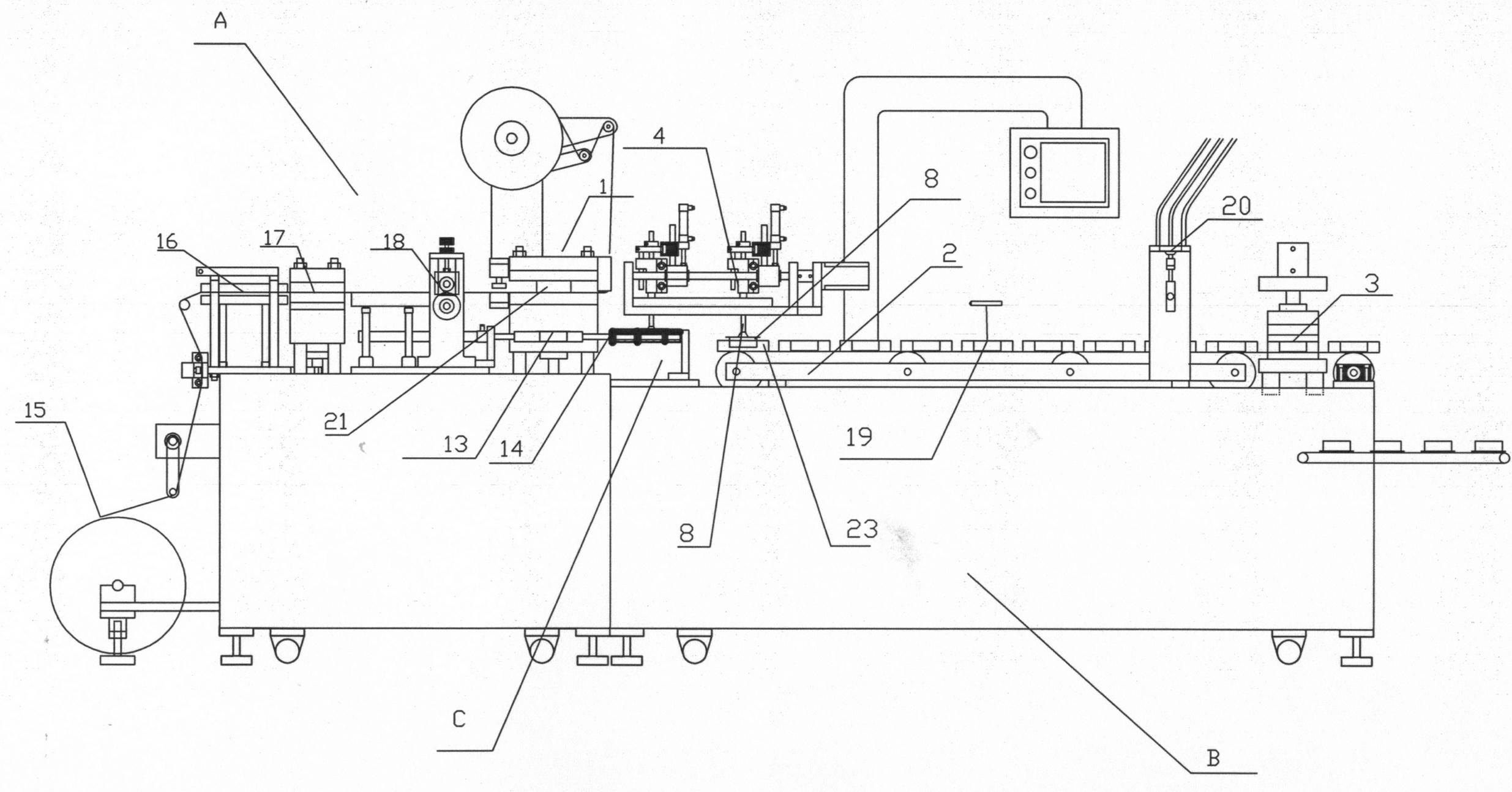

[0011] The paper-plastic packaging machine of the present invention is divided into two parts, the front part is the bottom support forming punching part A, the bottom support is made of PVC material or other plastic materials, and the rear part is paper card and bottom support heat sealing Forming part B, and the present invention is provided with the mechanical bottom support device 4 that connects two major parts between two major parts. The forming and punching part A of the bottom support is provided with an unwinding device 15 and a heating device 16 in turn, a forming device 17 is arranged in front of the heating device 16, a traction device 18 is provided in front of the forming device, and finally a traction device 18 is provided in front of the traction device 18. , that is, the tail of this part is provided with a cutting device 1, (note: the specific structures of the unwinding device, heating device, forming device, traction device and cutting device described here...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap