Excavation method for concrete quality defect of face rockfill dam toe slab during construction period

A technology for face rockfill dams and quality defects, applied in dams, barrages, water conservancy projects, etc., can solve the problems of manual cutting, labor and time-consuming, and achieve the effect of ensuring the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

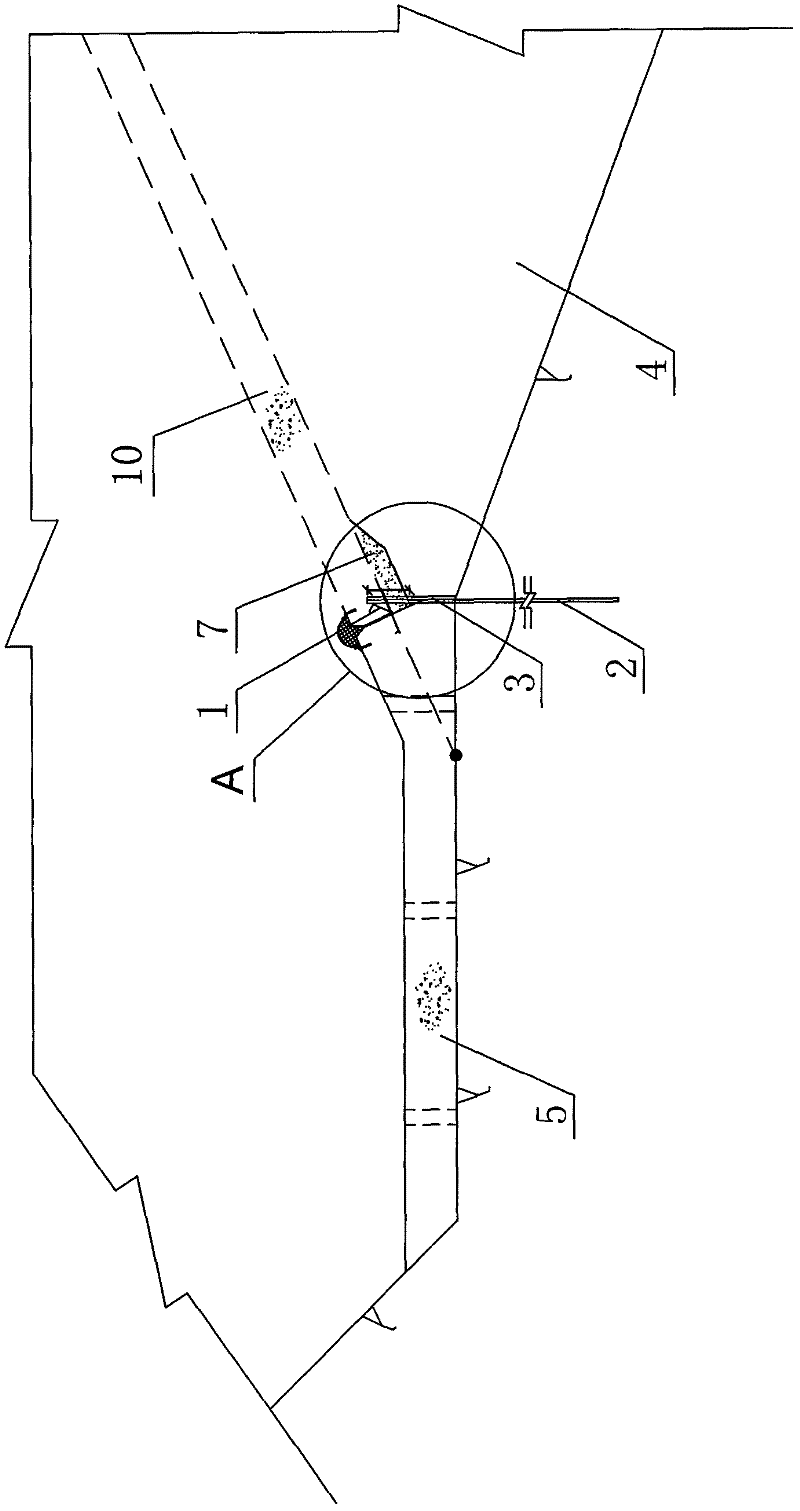

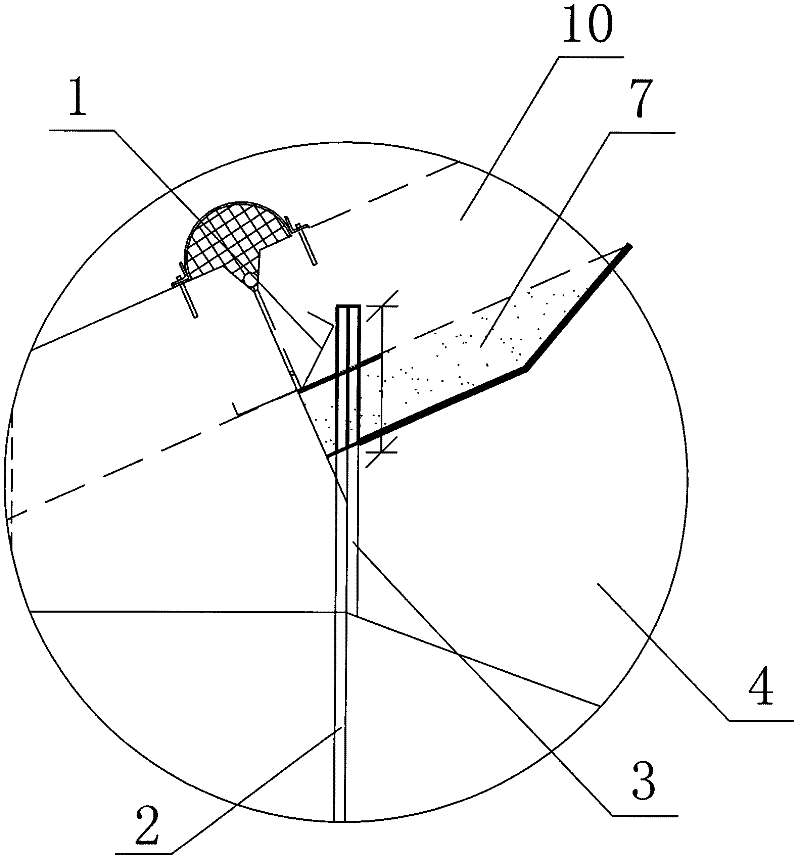

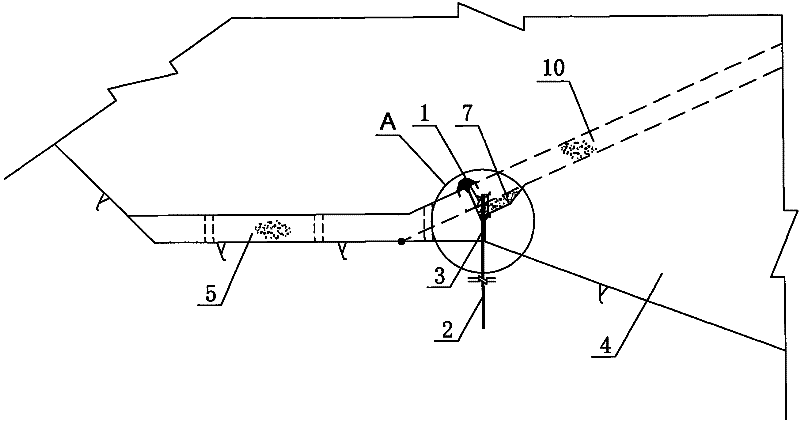

[0017] Such as figure 1 , figure 2 As shown, the construction steps of this embodiment are as follows:

[0018] a. Bend the exposed water-stop copper sheet 1 located at the 5 concrete toe slabs that need to be excavated, and do a good job of protection during the construction period;

[0019] b. Arrange a group of anchor bars 2 with a diameter of 28mm at the joint between the concrete plinth 5 and the dam body 4 to be filled. In order to ensure the anchorage strength, the anchor bars 2 need to go deep into the rock 2m, and the distance between adjacent anchor bars 2 is 1m;

[0020] c. At the junction of the concrete plinth that needs to be excavated and the dam body 4 to be filled, erect the steel formwork 3 welded and fixed with the anchor bar 2 close to the dam body 4 to be filled, wherein the steel formwork 3 is close to the dam body The 4 sides are fixed by internal pulling, and the height of the steel formwork 3 is 60-100cm (the thicker the concrete toe-slab, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com