Split Bamboo Soil Nails and Its Construction Method

A technology of soil nailing and bamboo, which is applied in excavation, infrastructure engineering, construction, etc. It can solve the problems of permanent impact on the soil layer, failure to recycle, buried steel bars, etc., and achieve the effect of convenient material acquisition, simple construction, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

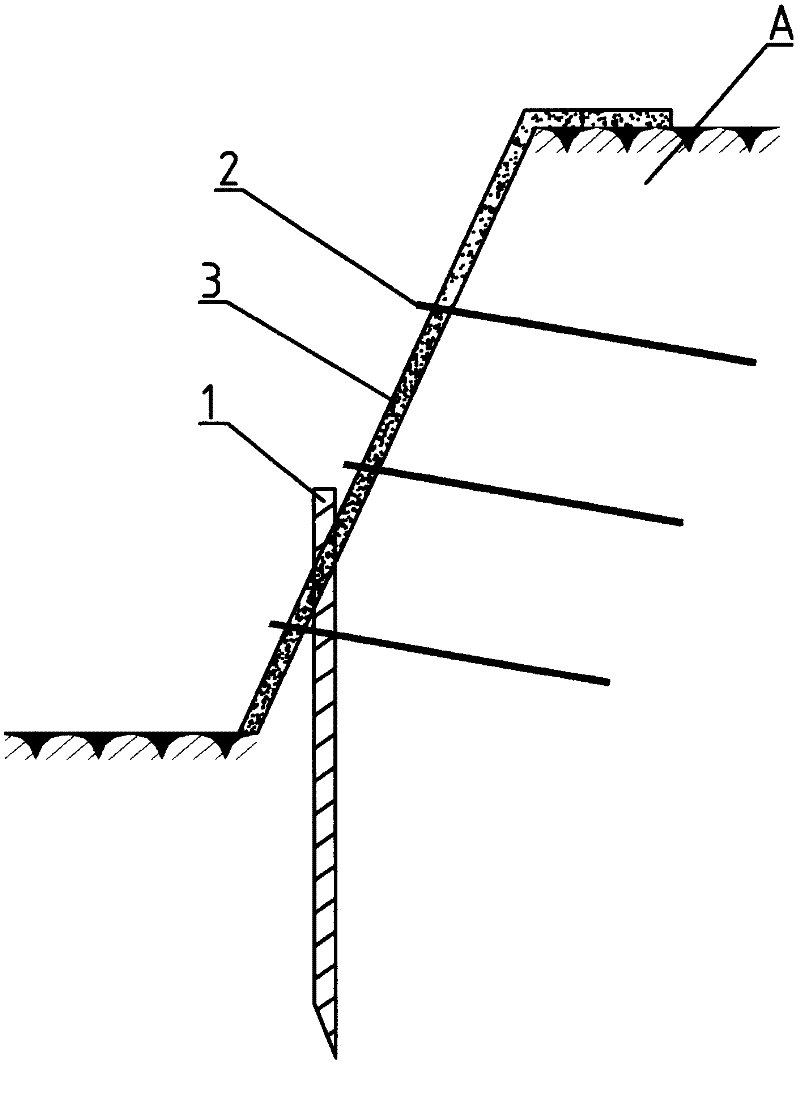

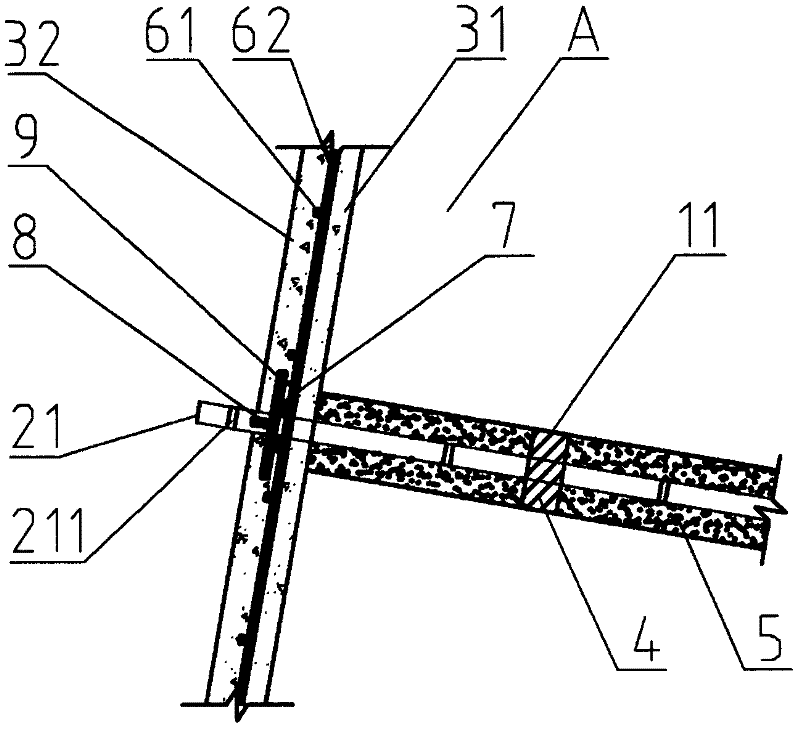

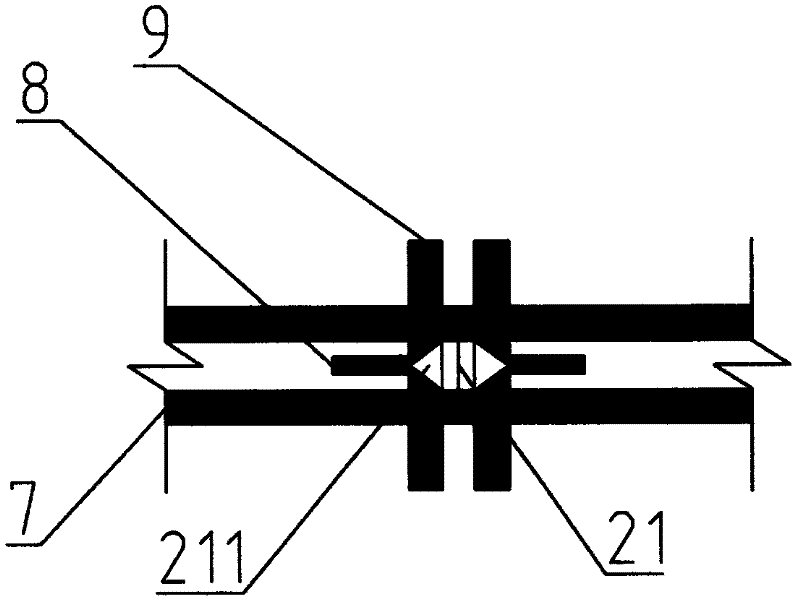

[0029] Example: see Figures 1 to 5 As shown, the split bamboo soil nails include bamboo pipe pile 1, split bamboo strip soil nails 2, and slope protection concrete 3. Insert the diagonally downward split bamboo strip soil nails 2 into the soil layer A on the side wall of the foundation pit, at least two The lower part of the split bamboo strip 21 is fixed to the centered bamboo tube 4 at a certain distance, the upper part of the split bamboo strip 21 is pierced with thorns 211, the bamboo pin 8 is inserted and locked, the bamboo pin 8 is locked, and the vertically locked bamboo strip 9 is bound. Mortar or cement slurry 5 is filled in the drilled hole 11 in the soil layer; the slope protection concrete 3 is divided into two layers, the bamboo strip mesh 6 and the reinforced bamboo strip 7 are placed on the first layer of slope protection concrete 31, and the bamboo pin 8 is locked and vertically locked Bamboo strips 9 are embedded in the second layer of slope protection concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com