Grouting shim plate construction method

A construction method and backing plate technology, applied in infrastructure engineering, construction, etc., can solve the problems of failure to meet the installation technical requirements of foreign experts, increase human resources and construction time, and difficulty in ensuring strength, so as to shorten the installation period, Save manpower and ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

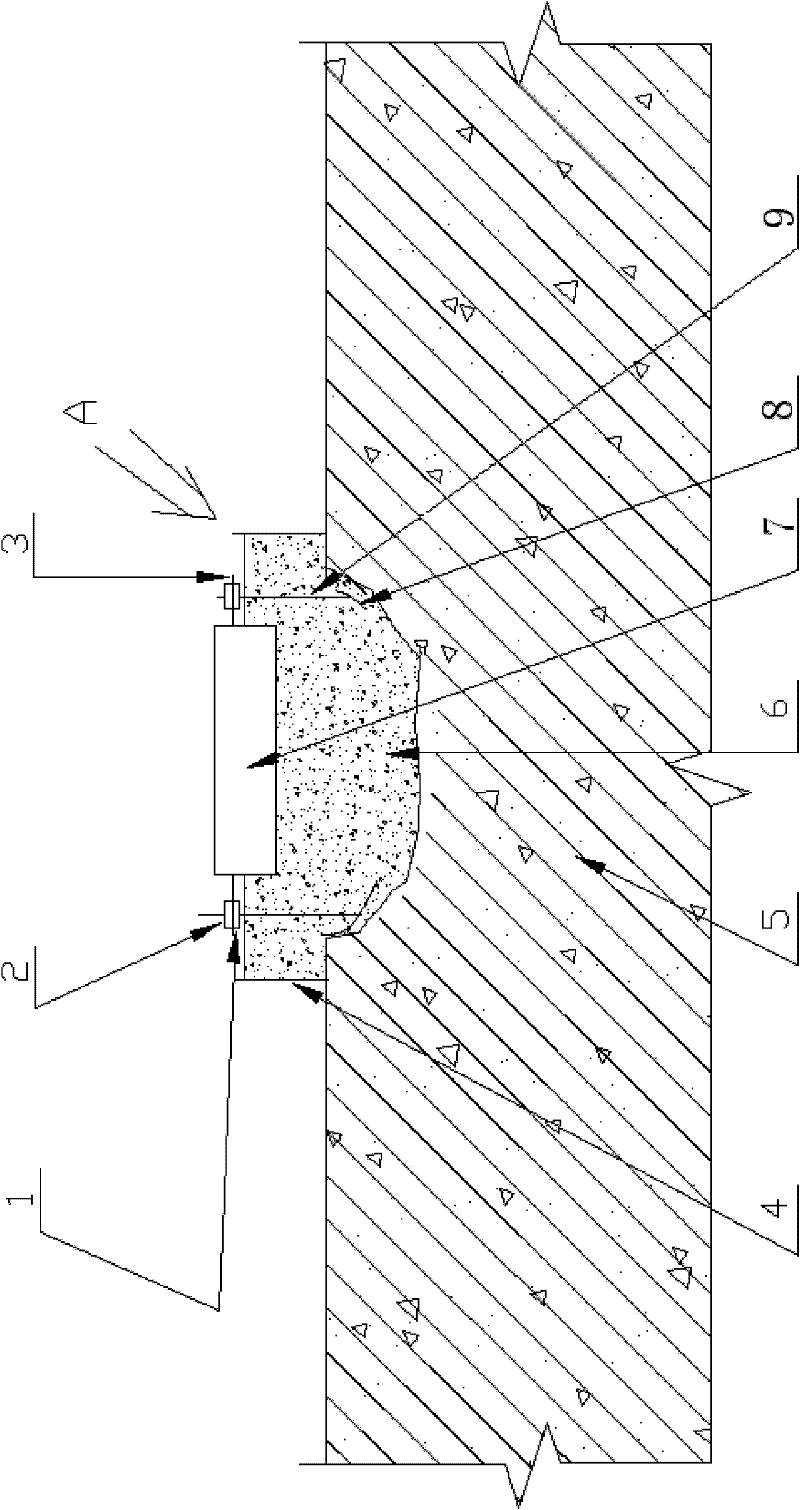

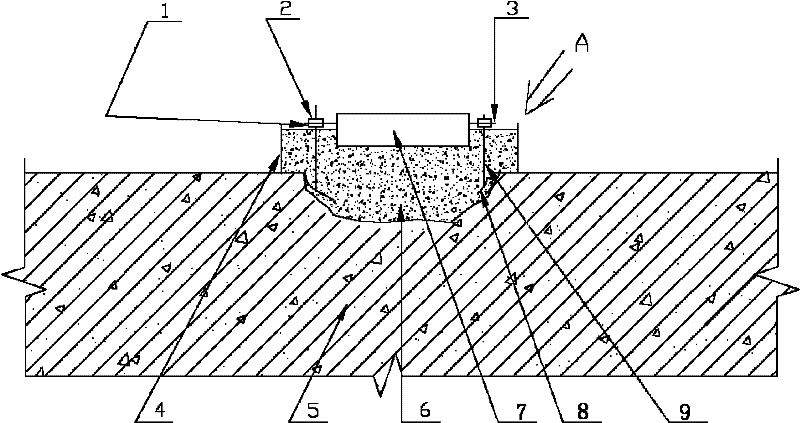

[0028] In order to make the present invention more clearly understood, the technical solution thereof will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] As shown in Figure 1, the grouting backing plate construction method of the present invention comprises the following steps:

[0030] (1) Utilize the principle of three points to determine a plane, weld the thin plate 3 fixed to it on the 3 points on the periphery of the backing plate 7 used, and set the round hole for installation on the thin plate 3, the thin plate 3 The thickness is 2~3mm;

[0031] (2) dig out the grouting pit 6 at the concrete foundation 5 positions where the pad iron 7 needs to be set, and expose the embedding bars 8 in the 5 positions of the concrete foundation, the length and width of the grouting pit 6 should be greater than the pad The length and width of the iron 7 are 80-120 mm, and the depth of the grouting pit 6 drilled into the foundation su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com