Aviation resistance furnace heating element layout method

A technology of heating elements and arrangement methods, applied in the direction of electric furnace heating, furnace components, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

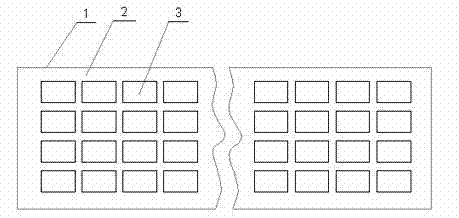

[0034] The invention belongs to an arrangement method of heating elements of an aviation resistance furnace, in particular, the optimized arrangement of the heating elements improves the furnace temperature uniformity of the aviation industrial resistance furnace. Such as figure 1 As shown, it is provided with a heating unit area 3 on the refractory support brick in the hearth 2 of the furnace body 1, and a space area 5 where the heating element unit 4 can be installed is arranged in the heating unit area 3; at least not less than 3 heating units The element units 4 are fixed in the space area 5, and the heating element units 4 in the space area 5 are connected in series to a power supply.

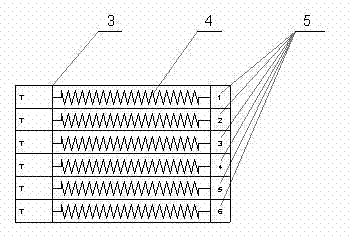

[0035] Such as figure 2 As shown, the heating unit area 3 is divided into 6 spaces, and at least 3 heating element units 4 can be placed in the 6 spaces and fixed in the space area 5 as required.

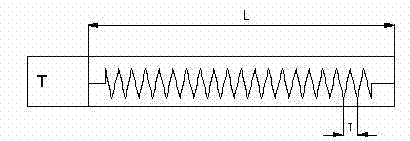

[0036] Such as image 3 As shown, it is a heating element unit with a pitch of T, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com