Measuring method for overall geometrical initial defects of structural components

A technology of geometric initial defects and structural components, applied in the direction of measuring devices, measuring instruments, mechanical measuring devices, etc., can solve problems such as inability to measure, and achieve the effect of simple and practical methods, high measurement accuracy, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a method for measuring the overall geometrical initial defect of a structural member. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

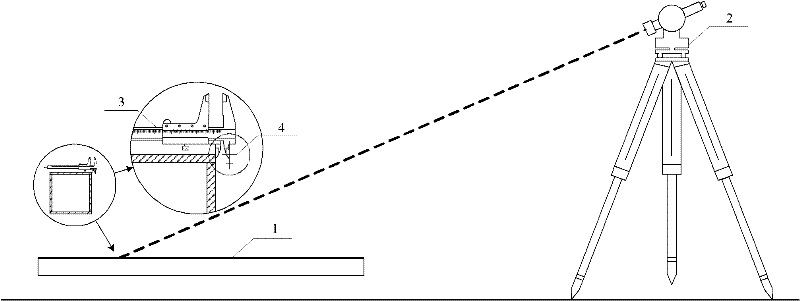

[0024] Examples (see figure 1 , figure 2 and image 3 ): This method is mainly realized by common optical theodolite 2 and vernier caliper 3.

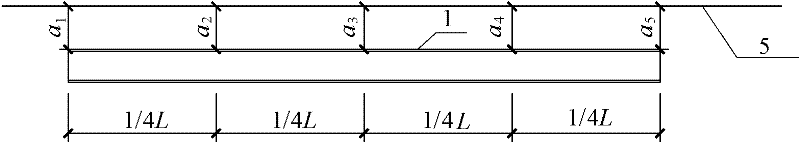

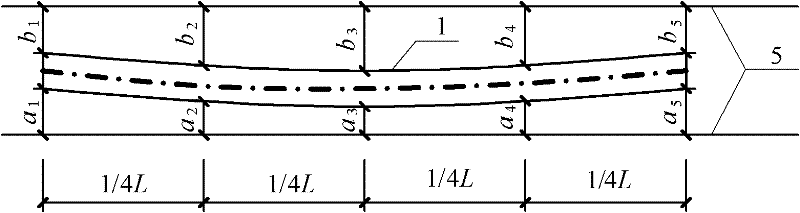

[0025] Place component 1 horizontally or vertically on the ground ( figure 1 placed horizontally), the optical theodolite 2 is mounted on a tripod, and the vertical axis is leveled and fixed so that the virtual straight line 5 swept out by the crosshairs 4 of the theodolite is located on one side of the component and parallel to the length direction of the component as far as possible. Attach one side of the vernier caliper 3 to the edge of a certain measurement cross-section position of the component, and try to ensure that the length of the caliper is perpendicular to the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com