A method for analysis and evaluation of measuring point accuracy of vibration acceleration sensor gearbox

A vibration acceleration and precision analysis technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as patent applications for algorithms that have not yet been discovered, and achieve the effects of easy to master and use, accurate algorithms, and reduced measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

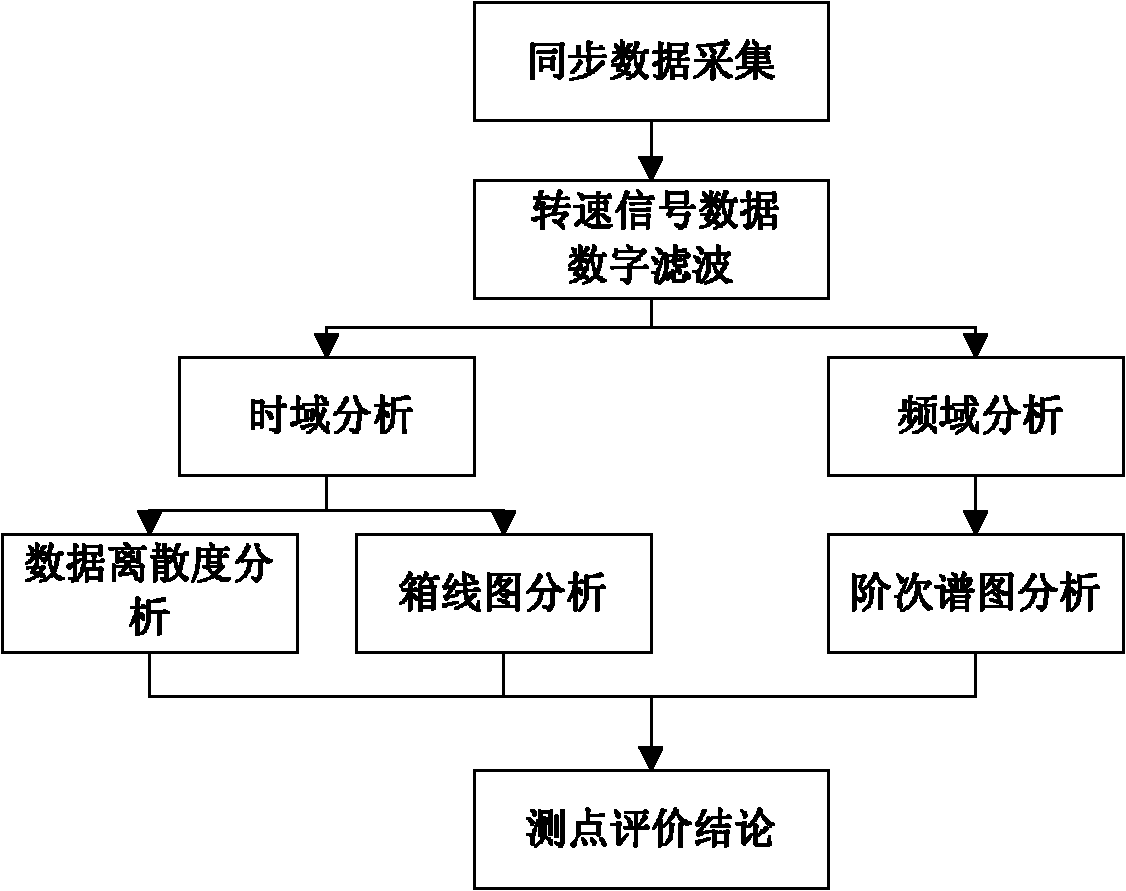

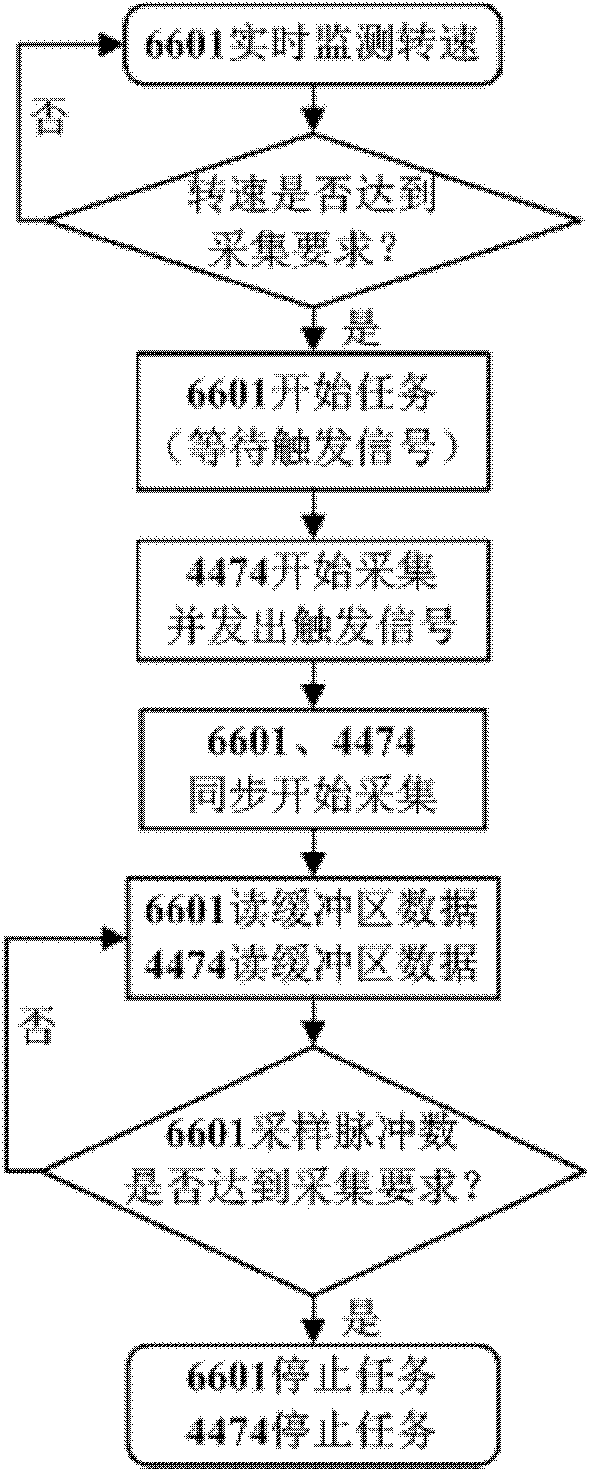

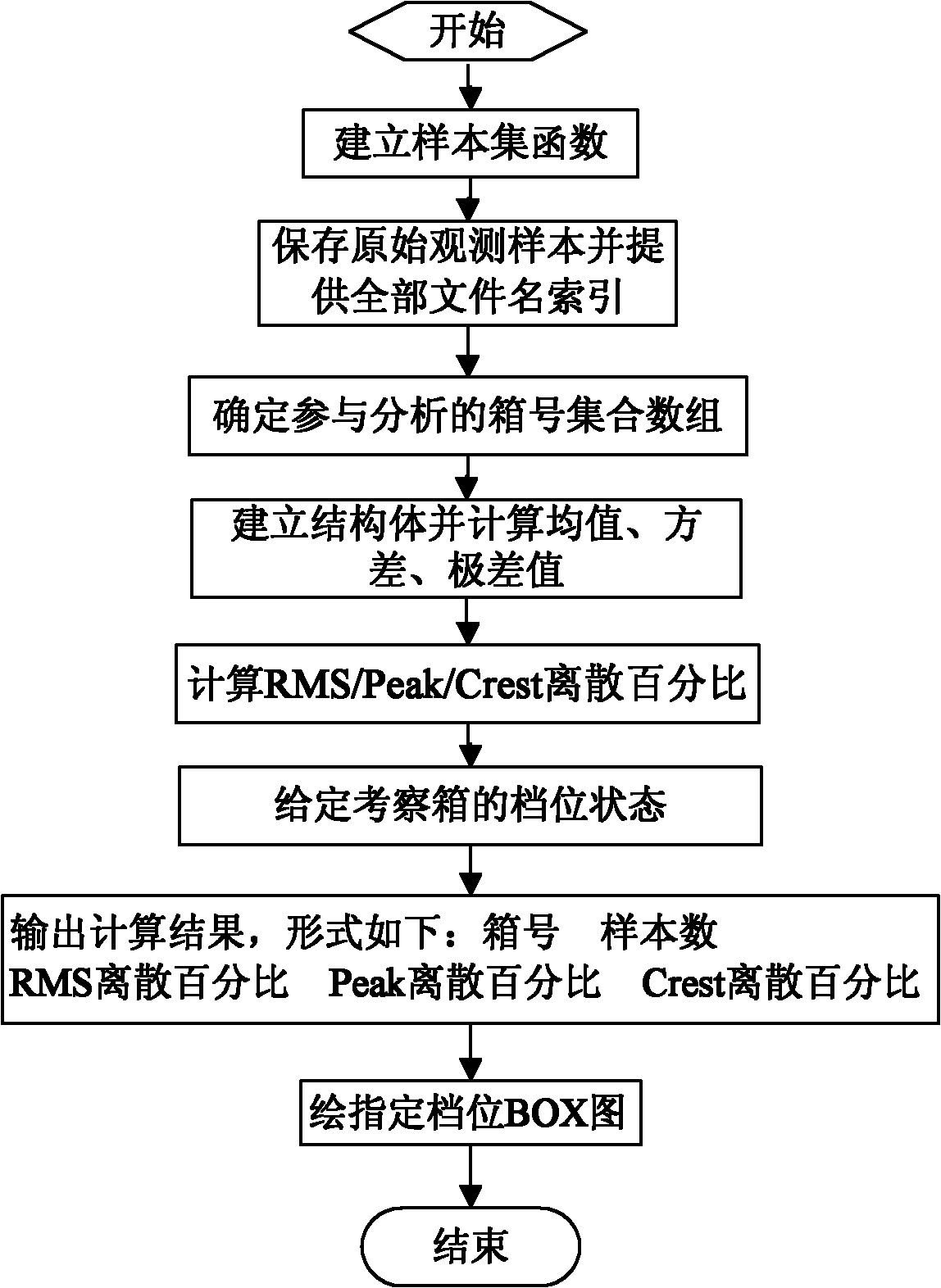

[0060] A method for analyzing and evaluating the measurement point accuracy of a vibration acceleration sensor gearbox, such asfigure 1 shown. Through the vibration acceleration sensor, the speed signal is the main control, and the synchronous data acquisition of the vibration signal and the speed signal is carried out for the gearbox; the time domain characteristic value is extracted for analysis and evaluation, and the average value RMS, peak value, peak index Crest, RMS / Peak / Crest discrete percentage, draw RMS-Peak diagram and box plot according to sensor position, sample number, RMS / Peak / Crest discrete percentage; obtain power spectrum and calculate order through time-domain synchronous averaging, data filtering, resampling, and FFT transformation Analyze and evaluate the spectrum; analyze the results through time domain analysis and fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com