Reaction Flywheel Output Torque Measuring Circuit and Measuring Method

A technology of reactive flywheel and output torque, applied in measuring devices, torque measurement, power measurement, etc., to achieve the effect of improving calculation accuracy, simple design and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

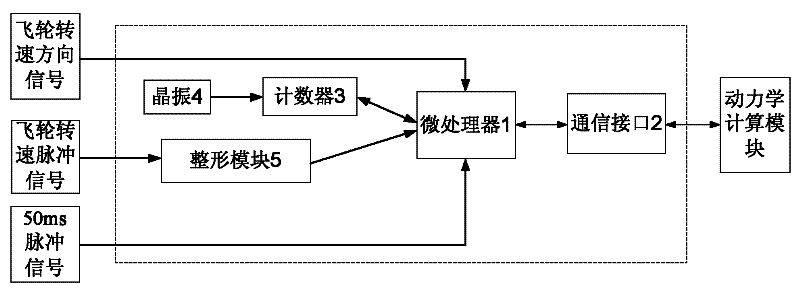

[0026] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises microprocessor 1, communication interface 2, counter 3, crystal oscillator 4 and shaping module 5; The first input and output end of microprocessor 1 is connected with the first output and input end of communication interface 2, The first input and output end of the microprocessor 1 is the communication input and output end, the second input and output end of the communication interface 2 is the signal input and output end of the dynamic calculation module, the second input and output end of the microprocessor 1 and the counter 3 The output and input ends are connected, the third input end of the microprocessor 1 is connected with the output end of the shaping module 5, the first input end of the microprocessor 1 is the flywheel speed pulse signal input end of the microprocessor 1, and the input end of the shaping module 5 end is the input end of the flywheel speed pul...

specific Embodiment approach 2

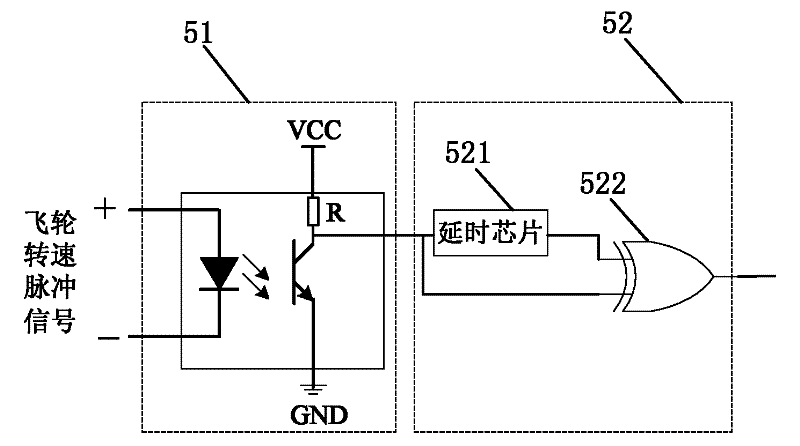

[0032] Specific implementation mode two: combination figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the shaping module 5 includes a photoelectric isolation shaping chip 51 and a frequency multiplication processing circuit 52,

[0033] The input end of the photoelectric isolation shaping chip 51 is the input end of the flywheel speed pulse signal, and the output end of the photoelectric isolation shaping chip 51 is connected with the input end of the frequency multiplication processing circuit 52,

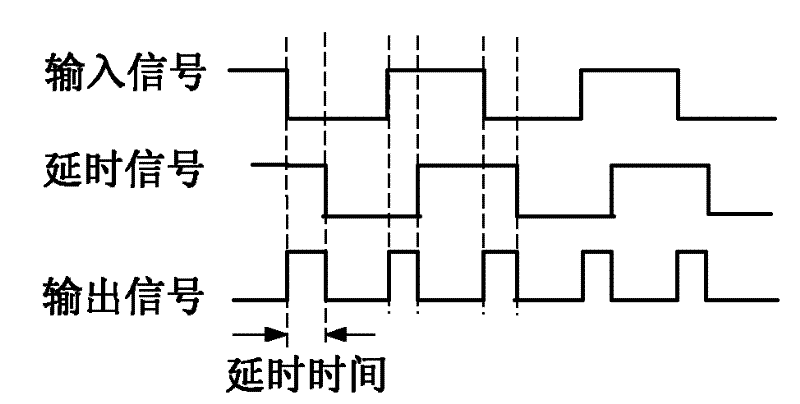

[0034] Frequency multiplication processing circuit 52 comprises delay chip 521 and XOR module 522, the input end of frequency multiplication processing circuit 52 is the input end of delay chip 521 and an input end of XOR module 522 simultaneously, the output end of delay chip 521 It is connected with the other input terminal of the exclusive OR module 522 , the output terminal of the exclusive OR module 522 is the output...

specific Embodiment approach 3

[0038] Specific embodiment three: the measurement method of the flywheel output torque of the present embodiment:

[0039]Microprocessor 1 initialization, set the interrupt trigger mode of the interrupt port of the flywheel speed pulse signal input terminal of microprocessor 1 to rising edge or falling edge trigger mode, that is, single edge trigger, set the interrupt of the 50ms pulse signal input terminal of microprocessor 1 The interrupt trigger mode of port is rising edge trigger; Microprocessor 1 defines the flywheel speed pulse interrupt count variable count and clears it; sets the internal timer of Microprocessor 1, the timing accuracy is 1ms, and starts timing;

[0040] Initialize counter 3, set the count of counter 3 to increase by 1 to represent 1 μs, start counter 3 to count; initialize 50ms interrupt update flag flag=0;

[0041] Set the priority of the 50ms pulse interrupt handler to be higher than that of the flywheel speed pulse interrupt handler;

[0042] The 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com