Stiffened wall plate compression stability test support fixture and end support coefficient test method

A technology for stability testing and reinforced wall panels, applied in the direction of applying stable tension/compression to test material strength, measuring devices, strength characteristics, etc., can solve complex and lengthy problems, low practicability, and no general value, etc., to achieve The effect of shortening the test period, improving the loading accuracy and reducing the test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below through specific embodiments:

[0047] The test methods for the support coefficient of the loading end of the panel compression stability test mainly include: commissioning design, test installation, load measurement and load comparison.

[0048] Among them, the design of the commissioning piece: the wall plate is a flat test piece, the material is required to be the same as the test piece, and the end clamping section is the same as the test piece.

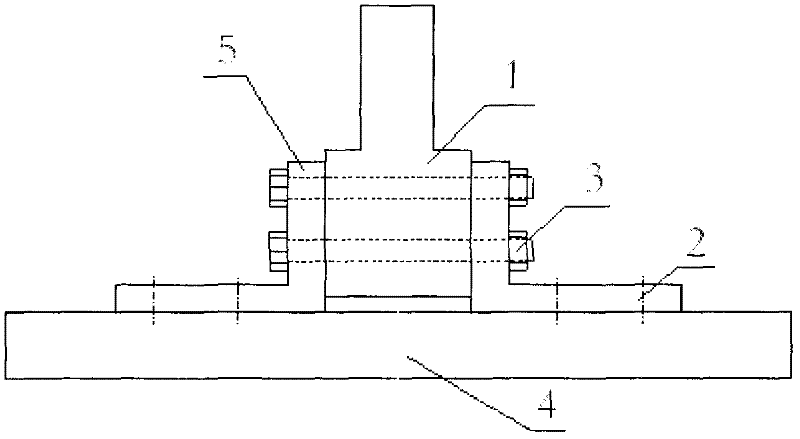

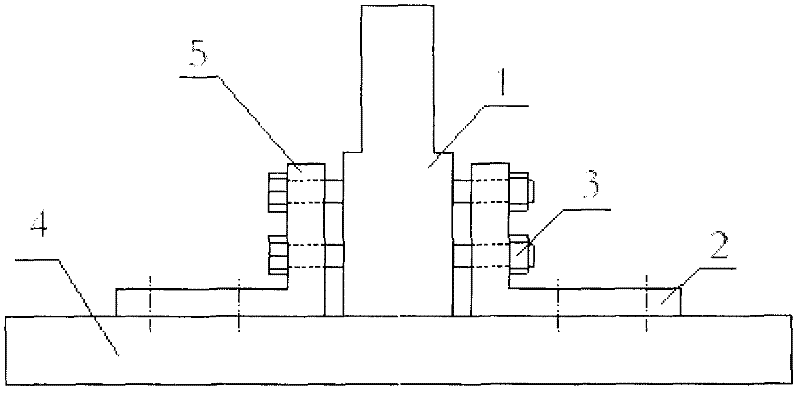

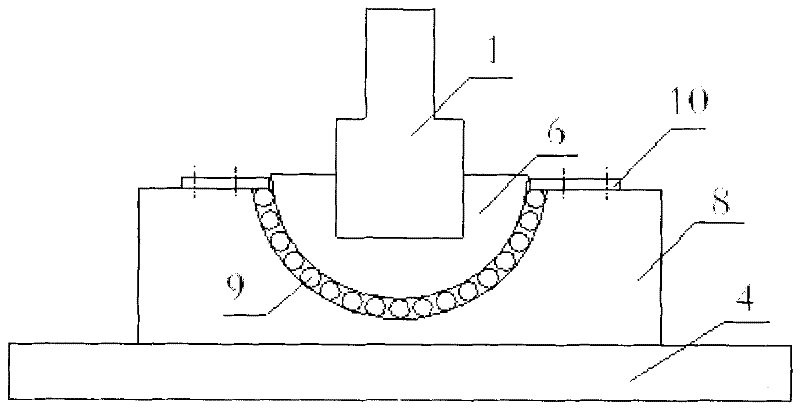

[0049] Test installation: the positioning support is installed on the testing machine (loading frame) according to the axis, the grooved semi-cylinder is placed in the arc groove on the positioning support, the test piece is inserted in the semi-cylindrical groove, the roller and the semi-cylindrical or The loading end of the debugging part is in line contact, the distance from the center to the plane of the positioning support is H, and the installation supports the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com