Heating device for Hopkinson pressure bar test

A technology of Hopkinson compression rod and heating device, which is applied in the direction of measuring device, testing material strength and instruments using one-time impact force, and can solve the problem of large error of simple thermal insulation positioning device, inconvenient adjustment of simple heating device, and inaccurate positioning of test pieces To achieve the effect of improving the test success rate, avoiding temperature loss and temperature unevenness, and convenient operation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

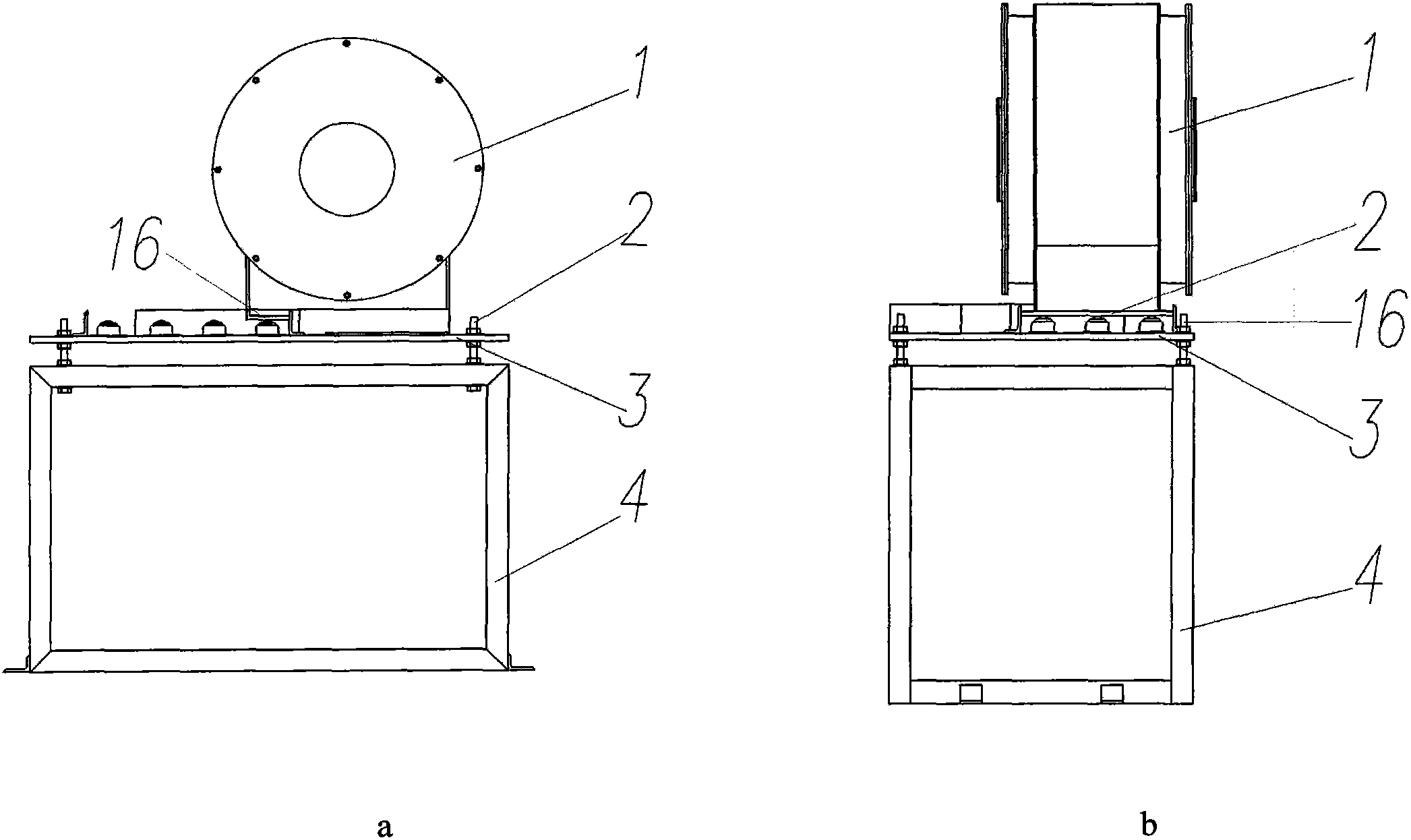

[0034] This embodiment is a heating device for Hopkinson compression bar test, including a mobile support platform, a tubular heating furnace and an electrical control box. The mobile support platform is composed of a slide plate 3 and a bracket 4. The tubular heating furnace is an integral type, including an end cover 5, a corundum tube 6, an insulation cover 7, an insulation lining 8, an aluminum silicate fiber blanket 9, a furnace shell 10, and a heating element 11. Gasket 12, heat-resistant steel pipe 13, heat-resistant brick 14 and base 16. The electrical control box is connected to the heating furnace through two heating wires and a temperature-measuring wire. The two ends of the heating wire are respectively connected to the electrical control box and the heating The heating element in the furnace is used to heat the test piece, and the two ends of the temperature measuring wire are respectively connected to the electric control box and the thermocouple placed in the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com