Insulation Thickness Design Method for High Voltage XLPE DC Cable

A cross-linked polyethylene, DC cable technology, applied in the direction of conductor/cable insulation, insulator, circuit, etc., can solve the problem of different breakdown strength, meet the requirements of electrical performance, ensure long-term stable operation, and reliable transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in more detail below in conjunction with specific embodiments.

[0072] Using the insulation thickness design method proposed by the present invention to design the insulation thickness of a 110kV single-core XLPE DC cable includes the following steps:

[0073] Step 1: Determine the form of the design voltage. When designing the insulation thickness of the HV XLPE DC cable, the designed voltage form is DC voltage U dc , Polarity reversal voltage U fz And DC voltage superimposed on transient overvoltage U pu ;

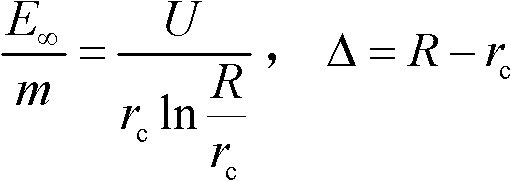

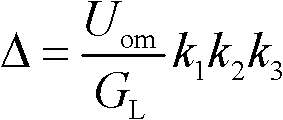

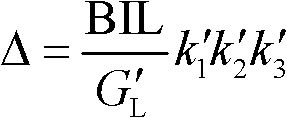

[0074] Step 2: Calculate the amplitude of the design voltage, DC voltage U dc The value is 110kV single-core XLPE DC cable long-term rated operating voltage U 0 , Is 110kV, namely U dc = U 0 =110kV, polarity reversal voltage U fz The value is 1.45U 0 , Which is U fz =1.45U 0 =160kV, and the transient overvoltage U is superimposed on the DC voltage pu The value is (1.1K+1.9) U 0 , Which is U pu =(1.1K+1.9)U 0 , K is the Badr c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com