Lead wire structure of c-level three-dimensional wound core dry-type transformer with suspended installation

A three-dimensional wound iron core, dry-type transformer technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of difficult DC resistance balance, large space occupation, complicated wiring, etc., to save location space, save space, The effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

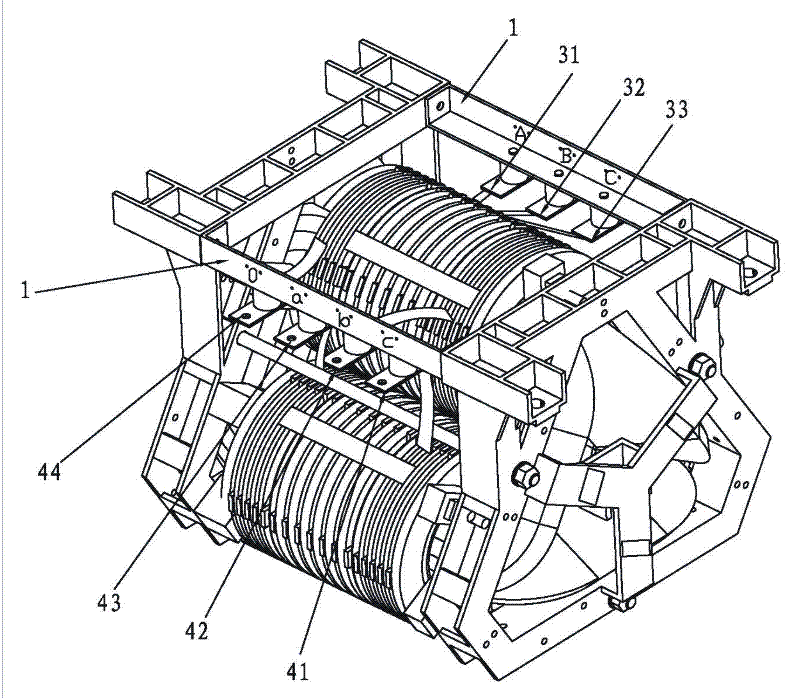

[0009] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but this does not constitute any limitation to the present invention.

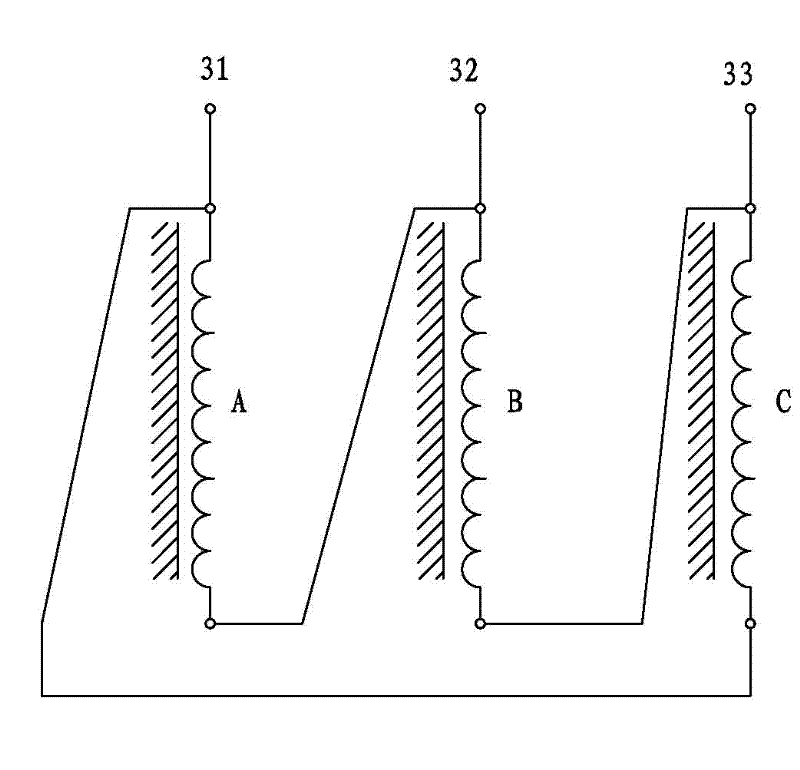

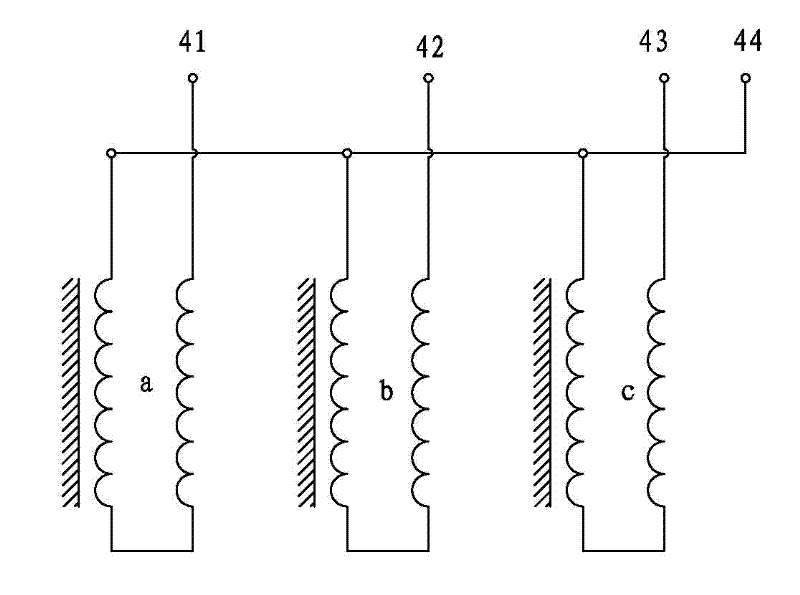

[0010] Such as figure 1 , figure 2 , image 3 As shown, the lead wire structure of the three-dimensional wound core dry-type transformer is composed of A, B, and C three-phase coils wound on the core column, and each phase coil is composed of a high-voltage coil and a low-voltage coil, and the high-voltage coil has three terminals. 31, 32, 33 and the low-voltage coil have four connection terminals 41, 42, 43, 44 respectively arranged on the lead brackets 1 located on both sides of the transformer;

[0011] Among them, the head of the A-phase high-voltage coil is connected to the terminal 31 and the tail of the C-phase high-voltage coil, the head of the B-phase high-voltage coil is connected to the terminal 32 and the tail of the A-phase high-voltage coil, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com