High-voltage flameproof three-phase asynchronous motor

A three-phase asynchronous, flame-proof technology, applied in asynchronous induction motors, electric components, electrical components, etc., can solve the problems of increased safety motor test difficulty, increased manufacturing and operating costs of specifications and models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

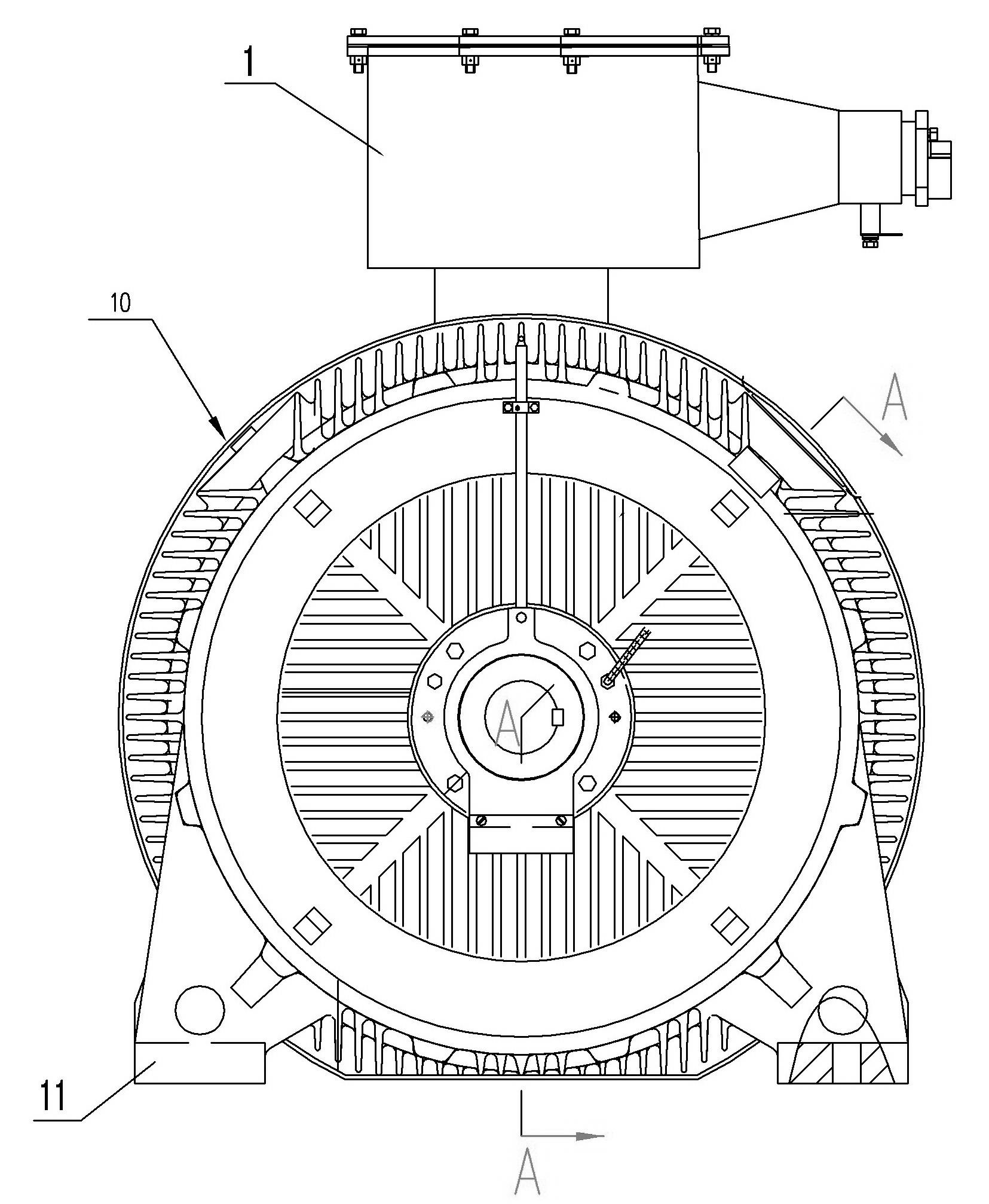

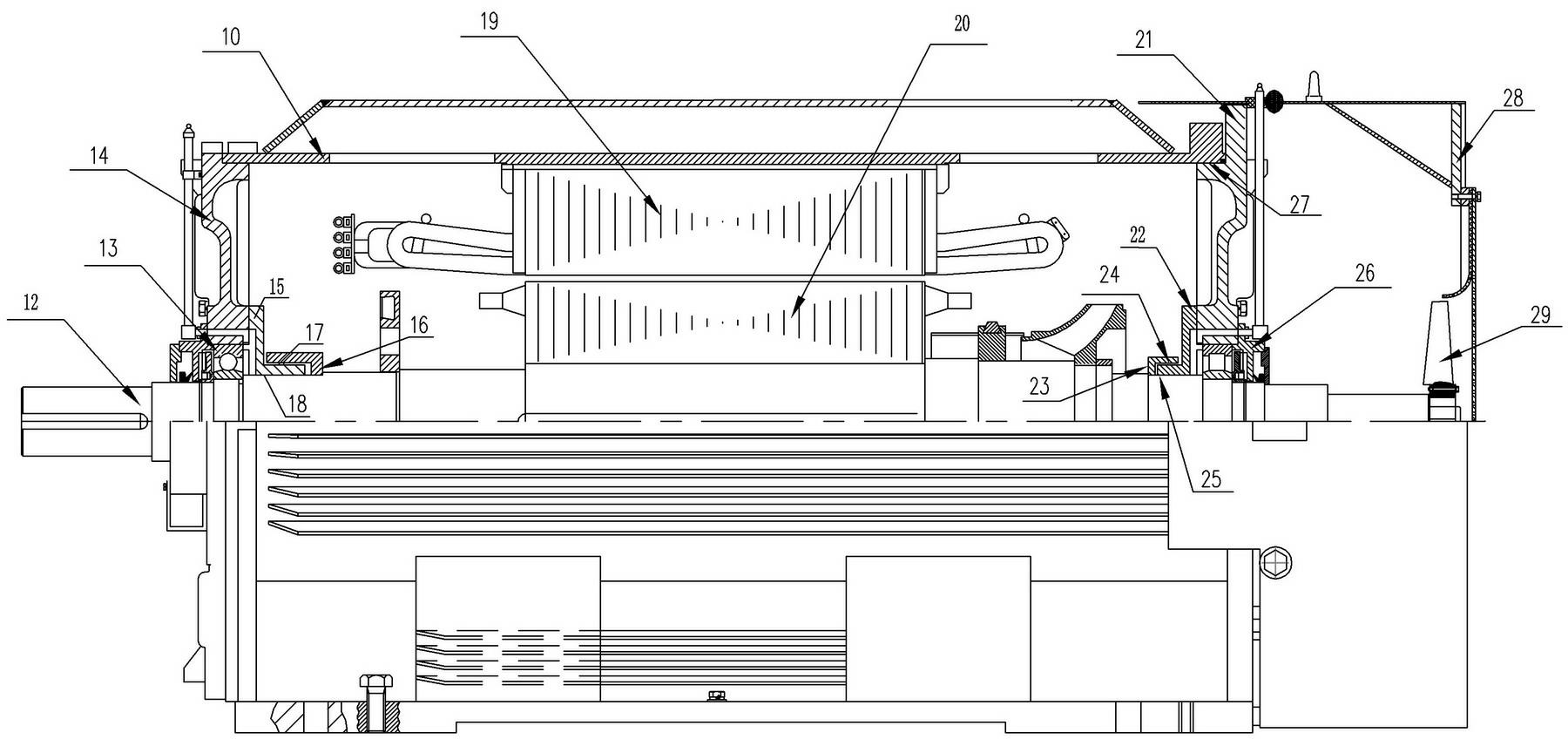

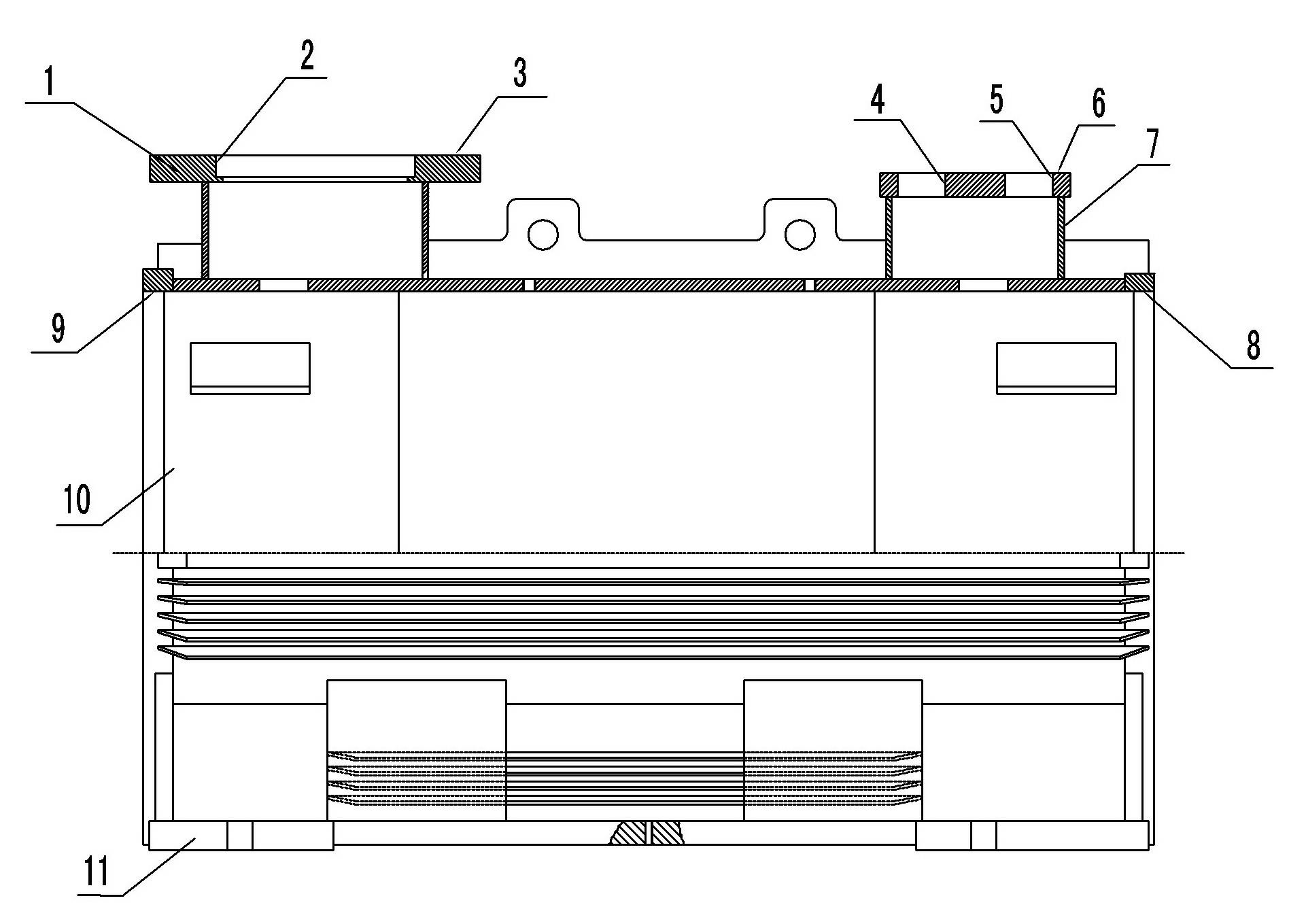

[0026] Example 1 A high-voltage flameproof three-phase asynchronous motor, see figure 1 , figure 2 , image 3 , including the base cylinder 10, the front end cover 14, the rear end cover 21, the rotating shaft 12 and the support, the base cylinder 10 and the foot plate 11 are connected into one body through the support plate, and the base cylinder 10 is provided with a high-voltage junction box The support 1 and the auxiliary junction box support 7 are respectively provided with bearing inner covers 15, 22 and matching curved road rings 16, 23 on the inner side of the joint between the rotating shaft 12, the front end cover 14 and the rear end cover 21, and the two match Form the curved road type flameproof joint surface structure at both ends (the double curved road structure is adopted, the length of the curved road ring and the inner cover of the bearing is between 18 and 40mm, and the flameproof gap is about 0.4mm, while the bearing The length of the explosion-proof cur...

Embodiment 2

[0027] Embodiment 2 A high-voltage explosion-proof three-phase asynchronous motor, which is basically the same as Embodiment 1, the difference is that: the curved path flameproof joint surface structure adopts a single curved path structure, and the flameproof curved path between the inner cover of the bearing and the shaft The flameproof length is between 15 and 70mm, and the flameproof gap is about 0.25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com