Closures for containers of medical liquids and containers for medical liquids

A container and liquid technology, used in the field of container caps and bottles, can solve the problems of the injection part being contaminated, not sterile, and the connection part being exposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

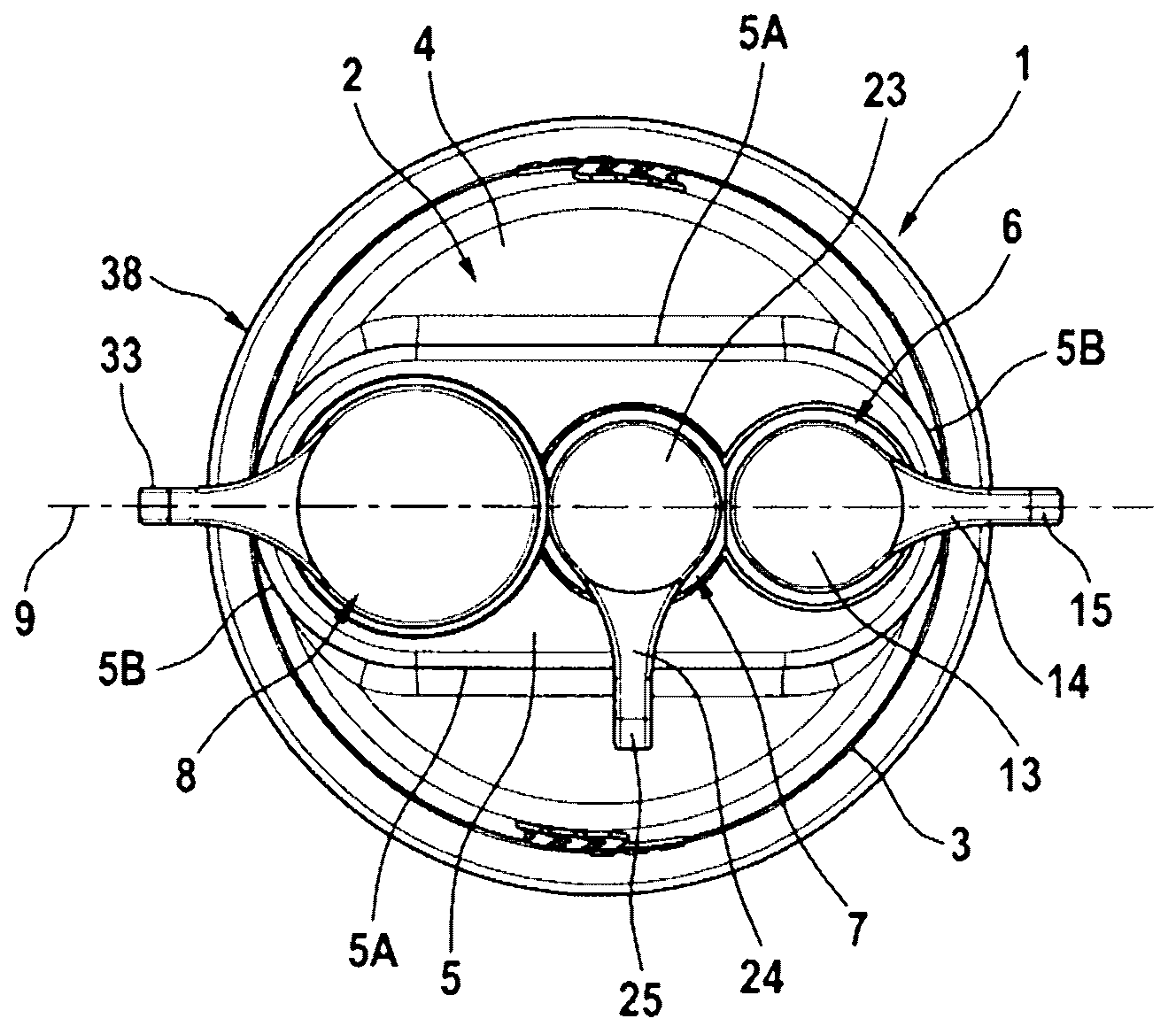

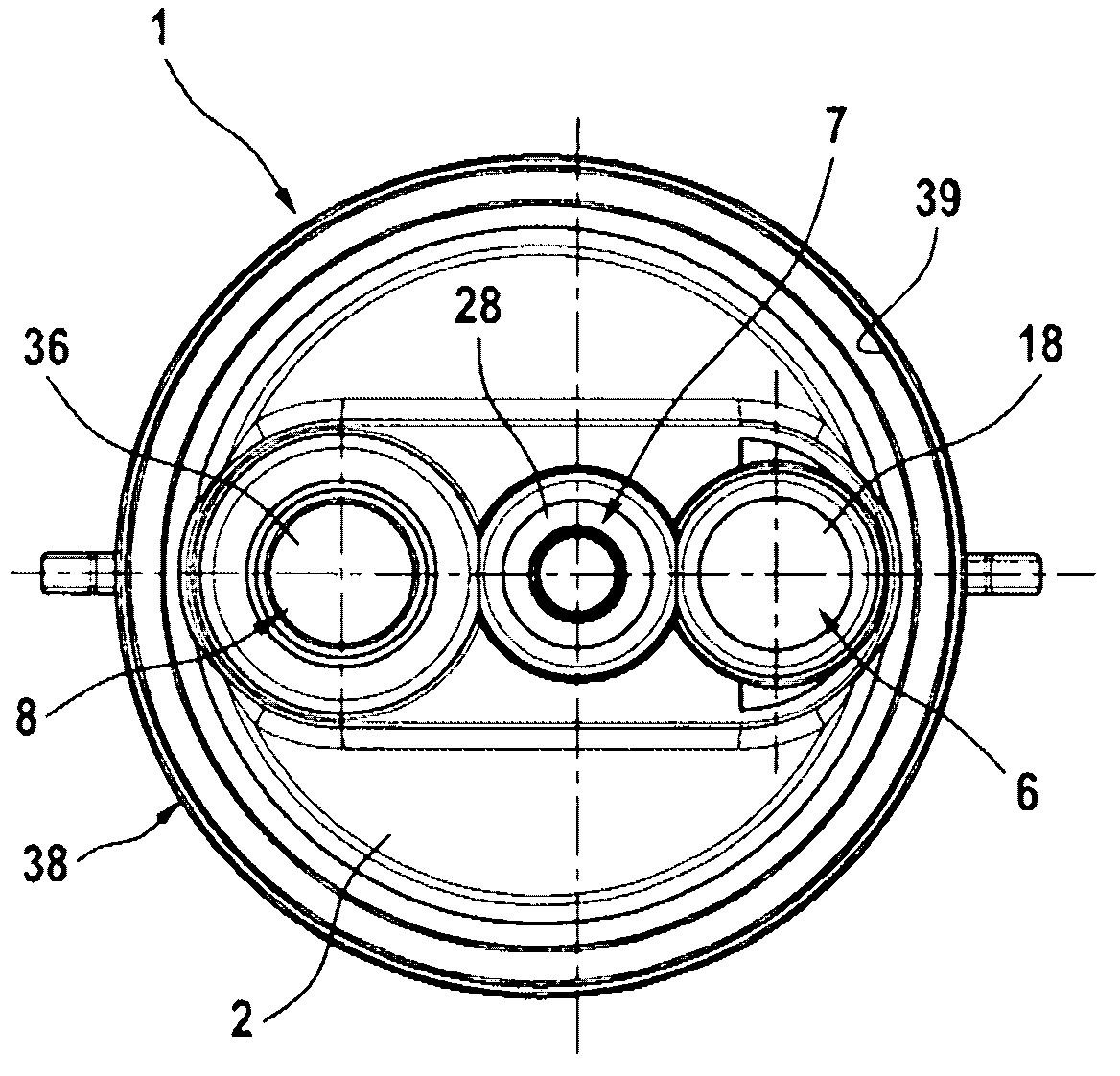

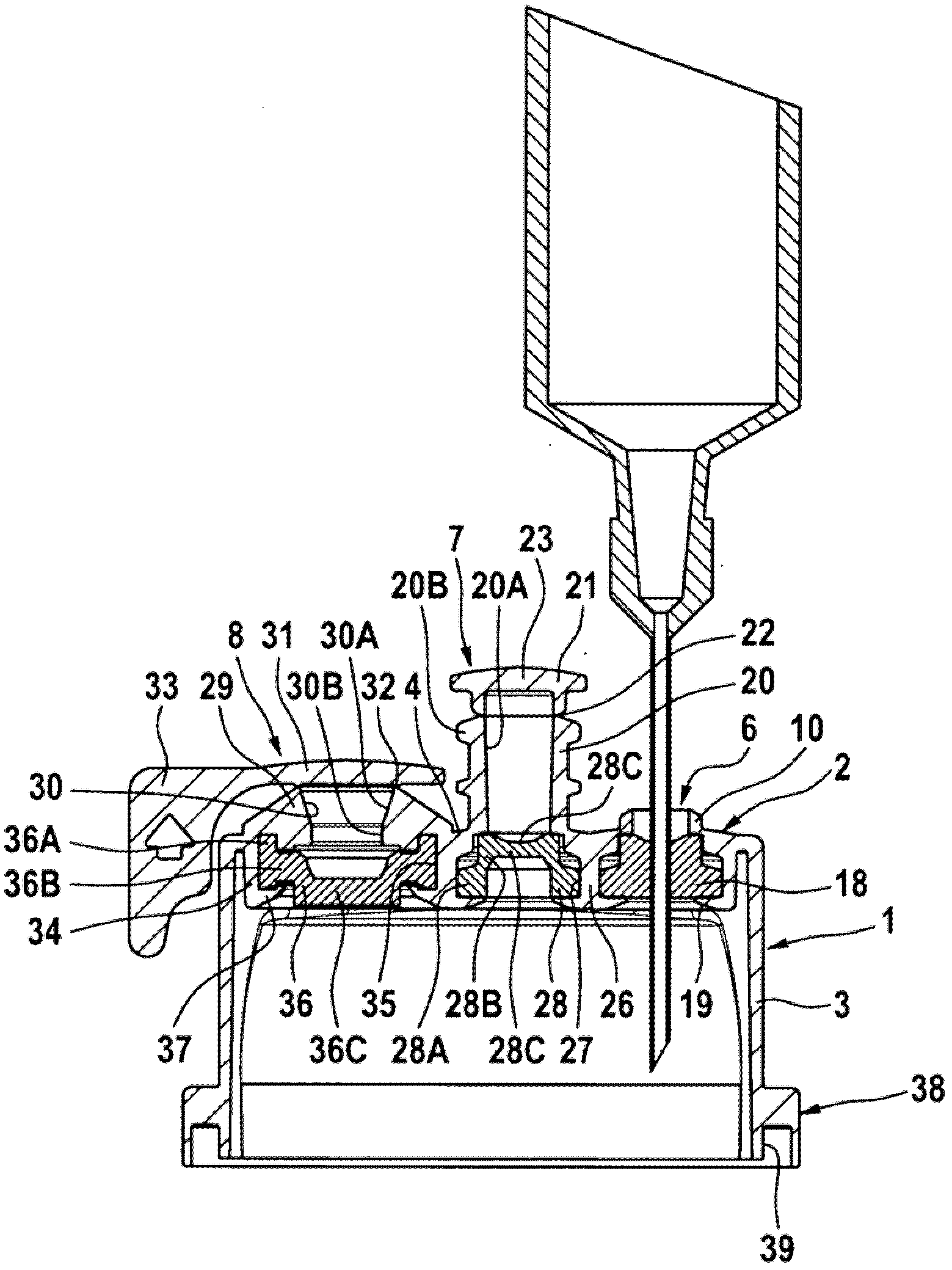

[0029] figure 1 and 2 A top view and a bottom view showing a first embodiment of a closure proposed by the present invention; Figures 3 to 5 A cross-sectional view of the closure is then shown, wherein an additive is injected with a syringe, or a medical liquid is withdrawn with a suction tip. Apart from the pierceable membrane, the closure is a one-piece plastic part which can be produced cost-effectively in large quantities.

[0030] The cover 1 has a cover part 2 and an edge part 3 . The cover 2 has a flat inner section 4 from which an outer section 5 protrudes outwards. The outer section 5 of the cover 2 has an elongated shape with two substantially rectilinear sections 5A, to which are adjoined on both sides an essentially semicircular section 5B. The outer section 5 extends over the entire width of the inner section 4 of the cover 2 . On the upper surface of the outer section 5 of the cover 2, there are a first injection part 6, a second injection part 7 and a remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com