A kind of special-shaped steel wire production method

A production method and steel wire technology, applied in the direction of wire drawing dies, etc., can solve the problems of rough surface, increased cost, and low dimensional accuracy, and achieve the effects of reducing production costs, reducing production processes, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

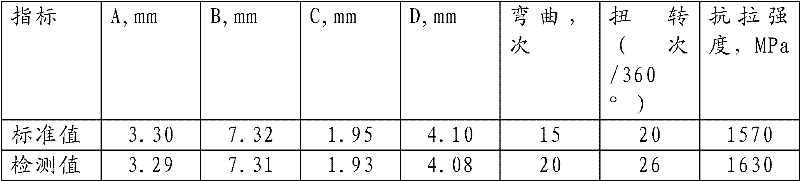

[0015] A special-shaped steel wire production method described in the present invention is described in detail by taking the production of a Z5-type (AB1-Tφ5.0mm) steel wire with a tensile strength of 1570MPa as an example to produce a sealed steel wire rope.

[0016] 1. Select raw materials. According to the cross-sectional area and tensile strength of the Z5 type (AB1-T) special-shaped steel wire, it is determined that the raw material steel grade is 82B, the diameter of the wire rod is φ10.0mm, and it is produced by continuous integral die drawing.

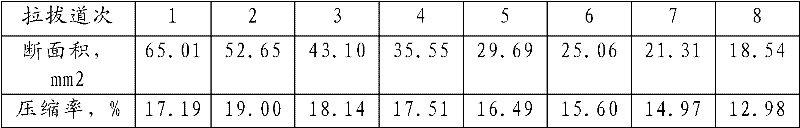

[0017] 2. Determine the drawing process. According to the calculation, the cross-sectional area of the Z5 (AB1-T) special-shaped steel wire is 18.54mm2, and the calculated total compression rate is 76.4%. In order to ensure the uniform deformation of the special-shaped steel wire and achieve smooth drawing, 8 drawing passes are designed to calculate the average partial compression The rate is 16.5%. In order to reduce the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com