Petroleum drill collar joint thread surface hot phosphating device

A thread surface phosphating device technology, applied in the field of oil drill collar joint thread surface thermal phosphating device, can solve problems such as unstable phosphating quality, affecting the service life of phosphating solution, pollution, etc., to reduce process operating costs and improve Drug utilization, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

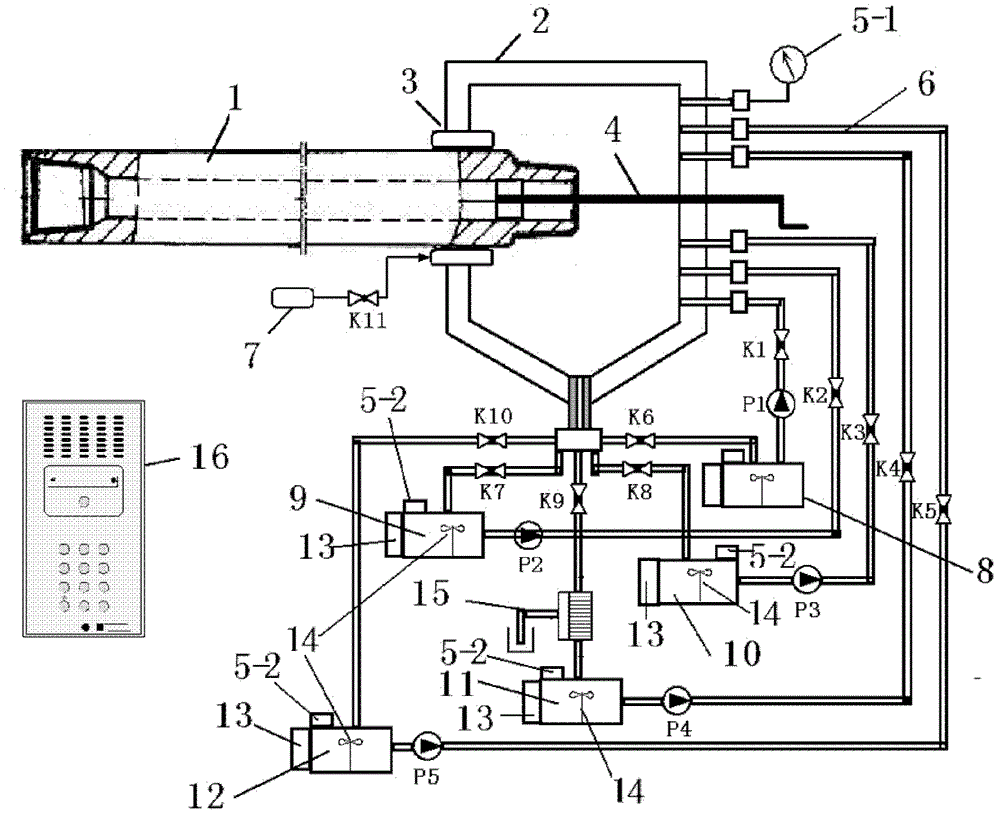

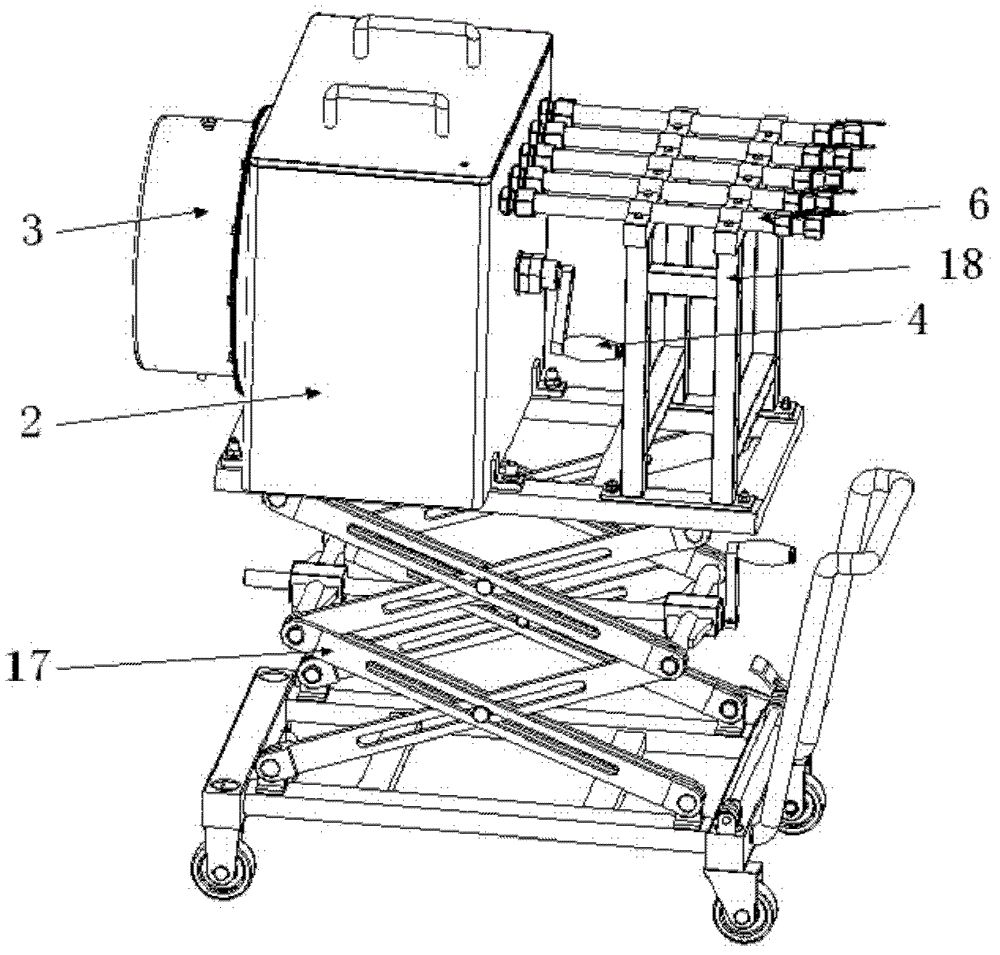

[0024] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The present invention is based on the commonly used oil drill collar size specification NC50-70.

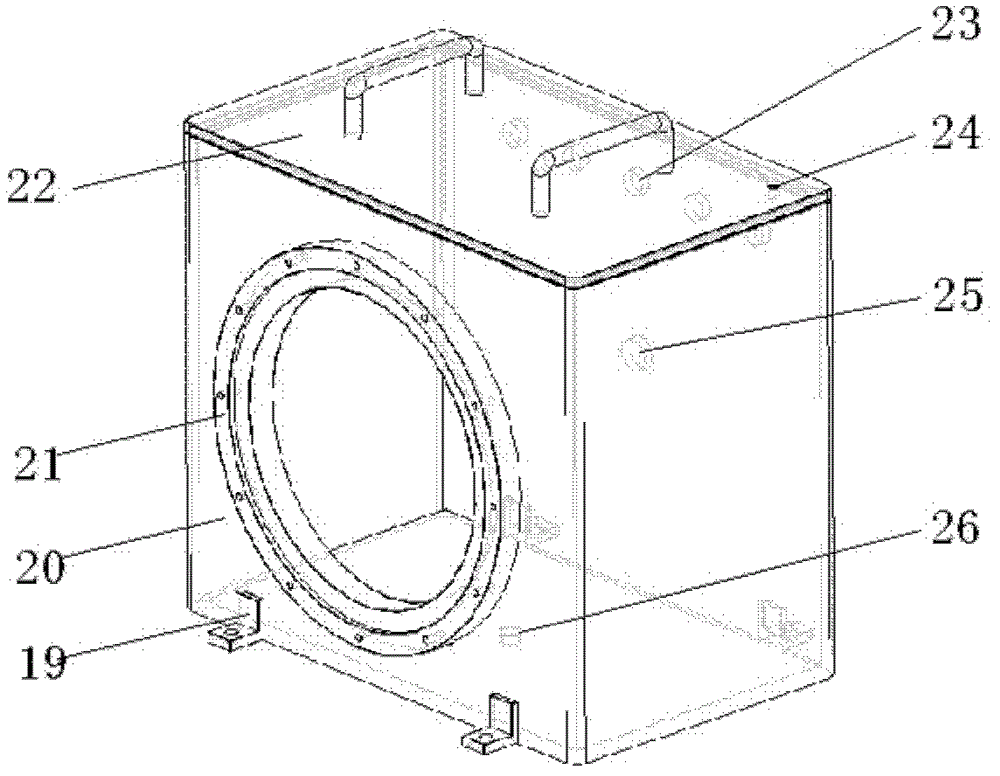

[0026] refer to figure 1 , figure 2 with image 3 , a thermal phosphating device for the threaded surface of a petroleum drill collar joint, comprising a phosphating tank bracket 17, the phosphating tank bracket 17 is connected to the phosphating tank assembly 2 with bolts through the phosphating tank connecting lug 19, and the phosphating tank assembly One side of 2 is connected with drill collar joint thread outer seal assembly 3 by bolts through outer seal box connection seat 21, and the other side of phosphating tank assembly 2 is connected with drill collar joint thread inner plug through inner plug assembly installation hole 25 The assembly 4 is connected, the five sets of manifolds 6 are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com