Construction method for partition wall lining in tunnel

A construction method and tunnel technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of difficulty in guaranteeing the construction quality of the partition wall lining, slow construction progress, and slow construction progress, so as to facilitate assembly line operation and meet fire protection requirements , Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

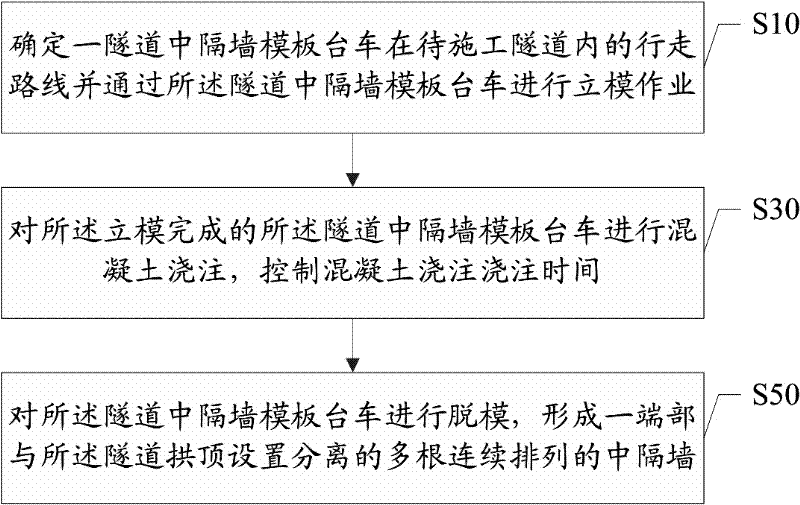

[0040] A construction method for lining a partition wall in a tunnel disclosed in an embodiment of the present invention includes the following steps:

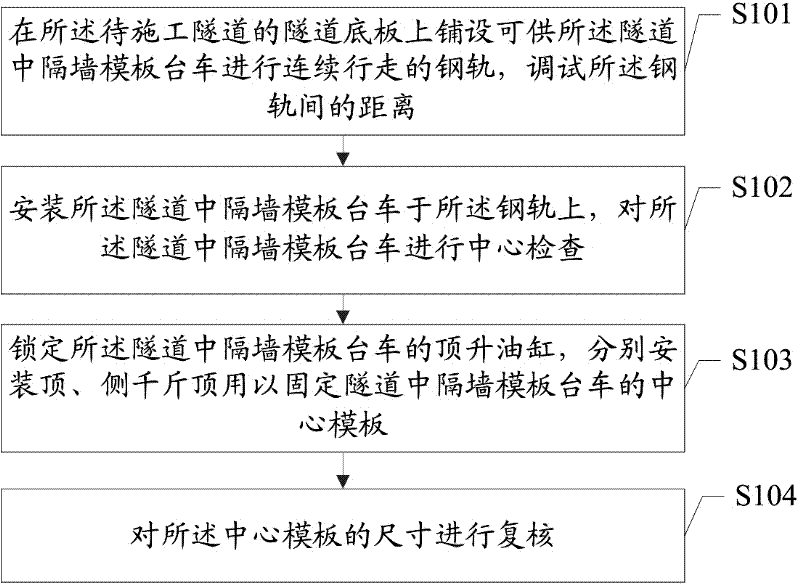

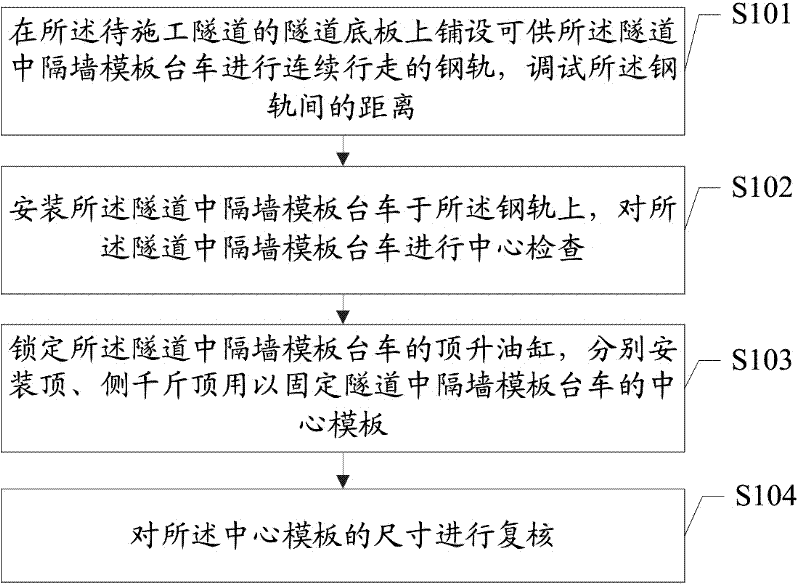

[0041] Determining the traveling route of a partition wall formwork trolley in a tunnel in the tunnel to be constructed and performing formwork through the partition wall formwork trolley in the tunnel;

[0042] Carry out concrete pouring on the partition wall formwork trolley in the tunnel completed by the vertical formwork, and control the pouring time of concrete;

[0043] The formwork trolley for the partition wall in the tunnel is demoulded to form a plurality of continuously arranged partition walls whose ends are separated from the vault of the tunnel.

[0044] see figure 1 , in step S10, determine the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com