Self-balancing prefabricated face and cast-in-situ core infilled wall

A prefabricated surface and self-balancing technology, which is applied to walls, building components, buildings, etc., can solve the problems of increased cost of the main structure, low strength of filling walls, and poor integrity. The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

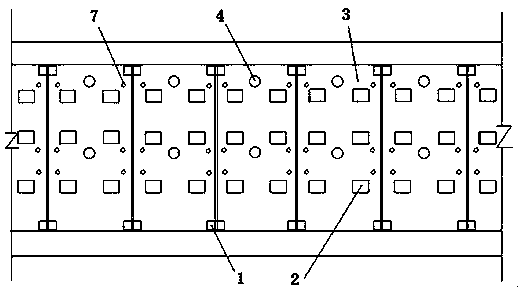

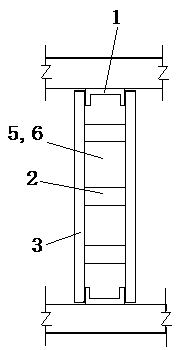

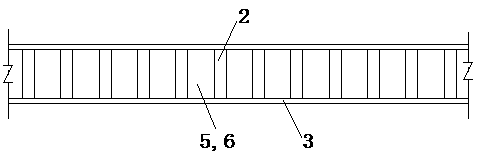

[0025] like Figure 1 to Figure 3 As shown, prefabricated components: prefabricated slab 3 (length 2850mm, width 1200mm, thickness 20mm) is attached with glass fiber mesh, the middle and top of the slab are provided with two pouring holes 4 with a diameter of 70mm, and the core material 6 is gypsum and cement (according to the volume ratio 3:1) it will be delivered to the construction site after mass production in the factory assembly line. The six connecting keys 2 and two prefabricated panels 3 are firmly assembled into a cavity mold, and the block positioning key 1 is mass-produced in the factory assembly line using recycled hard plastic (groove section, length 200mm, width 80mm, and 180mm). , thickness 80mm, wall thickness 10mm).

[0026] Core filling material 6: Set up sites in various places to produce local materials in batches, collect packaging foam plastic waste, crush them into granules, and then transport them to the construction site. Phosphogypsum dihydrate is t...

Embodiment 2

[0032] At the junction of adjacent cavity molds (the two-sided prefabricated panels 3 are bonded to the connection key 2), use the tension key (which can be bound with iron wire) to pass through the tension joint hole 7 to connect and fix the adjacent prefabricated panels 3 on the same side, The rest are the same as Embodiment 1.

Embodiment 3

[0034] Drill two rows of six joint holes 7 in total on the prefabricated plate 3 of the cavity mold, pass through the tension joint holes 7 with a ring cable (that is, a strapping belt), and clamp the two sides with wooden pins to make the two sides of the prefabricated plate paired 3 Pull together to resist the tension during watering. The rest are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com