A generalized predictive control system and method for air compressor anti-surge

A generalized predictive control and predictive control technology, applied in pump control, pump testing, mechanical equipment, etc., can solve problems such as power grid harmonic disturbance, the actual working point of the air compressor moving into the critical control area, dangerous surge area, etc., to achieve The effect of dynamic quality improvement, prevention of air compressor surge phenomenon, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

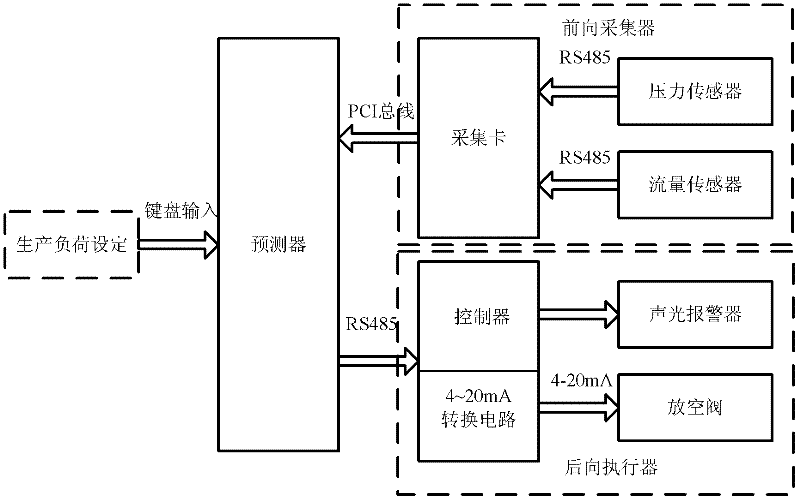

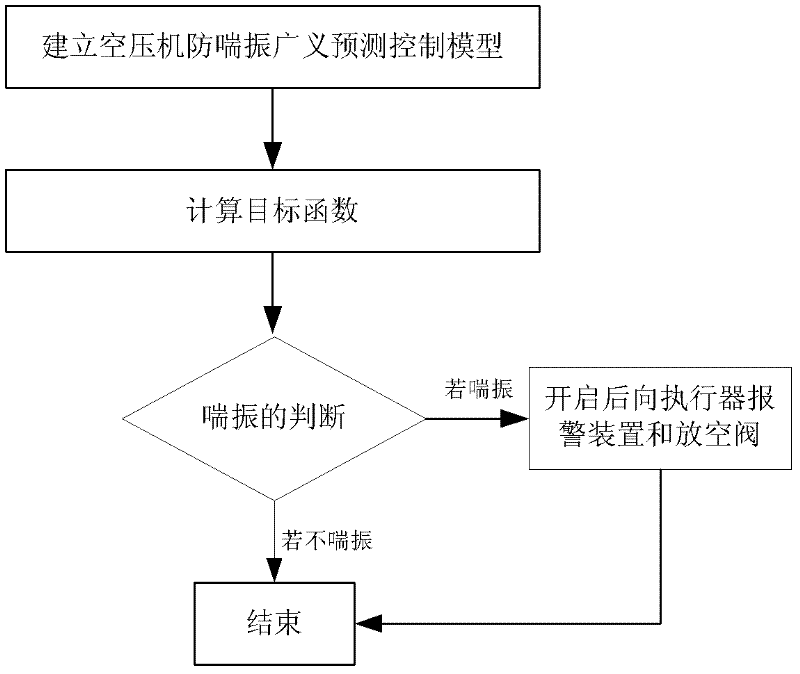

[0019] Such as figure 1 As shown, the air compressor anti-surge generalized predictive control system of the present invention includes a predictor, a forward collector and a backward actuator. The pressure at the outlet of the pipeline is constant, and with the change of production logistics, based on the principle of the minimum flow of the pipeline network, the area where the operating point of the air compressor is located is predicted, so as to realize the safe and stable operation of the air compressor under variable load conditions and avoid panting occurrence of vibration.

[0020] The predictor is the core of the system, using an industrial control computer, equipped with AMD PHENOM 8400CPU, 2G memory, 250G hard disk, PCI bus interface, RS485 communication interface, running Windows operating system, embedded with an air compressor written in c prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com