An electronic water pump for a vehicle

A technology for electronic water pumps and vehicles, which is applied to pumps, pump control, and components of pumping devices for elastic fluids, etc. It can solve the problems of limited natural heat dissipation capacity of the pump body, limited power density of the water pump, and low power density. , to facilitate speed regulation, improve heat dissipation, and increase power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

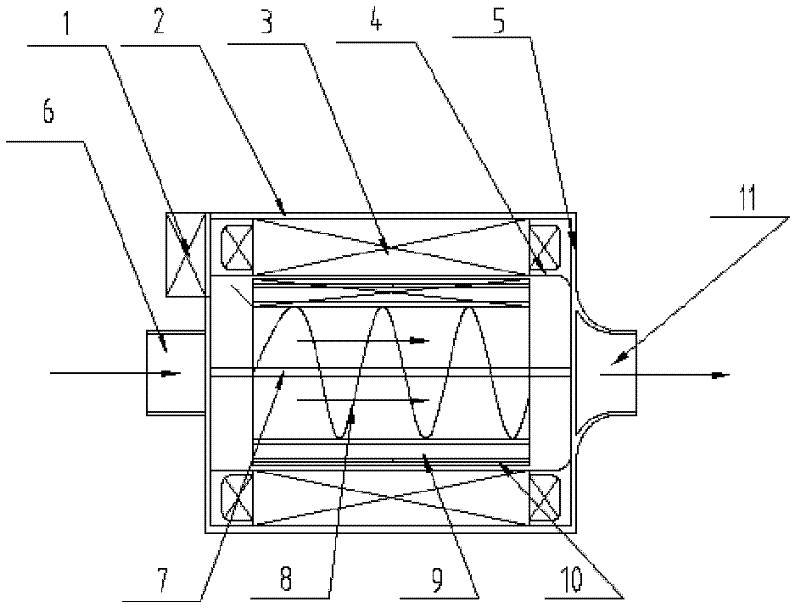

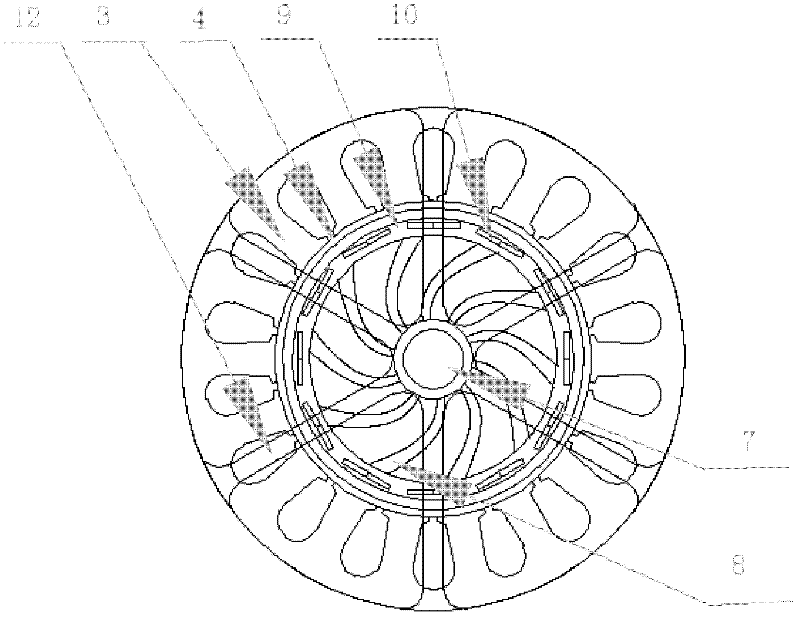

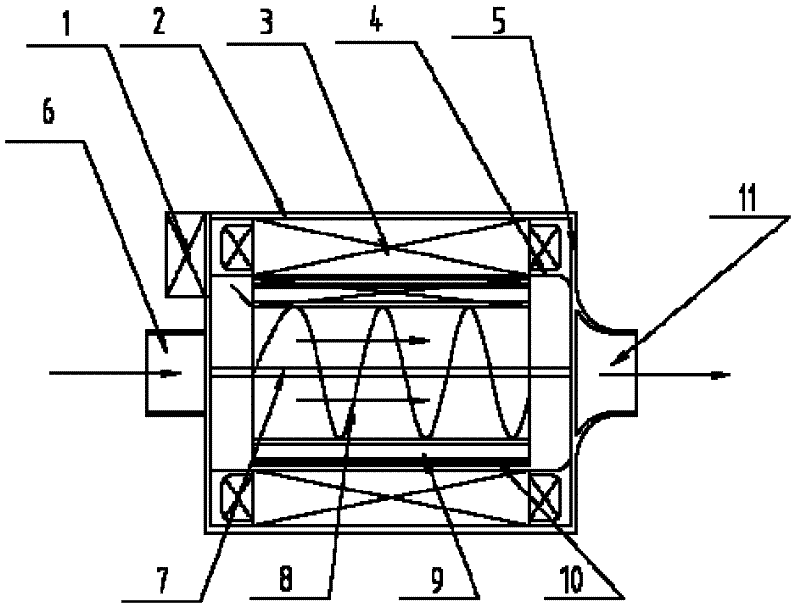

[0032] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0033] As shown in the figure, the water pump is mainly divided into three parts, the casing part: water inlet 6, end cover 5, casing 2 and water outlet 11, stator part, stator 3, control module 1, plastic sealing layer 4, rotor part: rotor shaft 7. Rotor worm support 8, rotor magnetic steel 9 rotor iron core (with plastic sealing structure) 10.

[0034] The turbine water pump structure using low energy consumption permanent magnet brushless DC motor as power, as shown in the figure, the stator part of the water pump motor: After winding, install the stator assembly into the water pump casing, and use the plastic sealing process to seal the whole The stator is plastic-sealed. After plastic-sealed, a rotor cavity is formed inside the stator. After plastic-sealed, the stator-rotor air gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com