A wire rope anti-twist connection device

A connecting device and wire rope technology, applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc., to achieve simple and fast connection and fixation, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific example, the specific embodiment of the present invention is described in further detail:

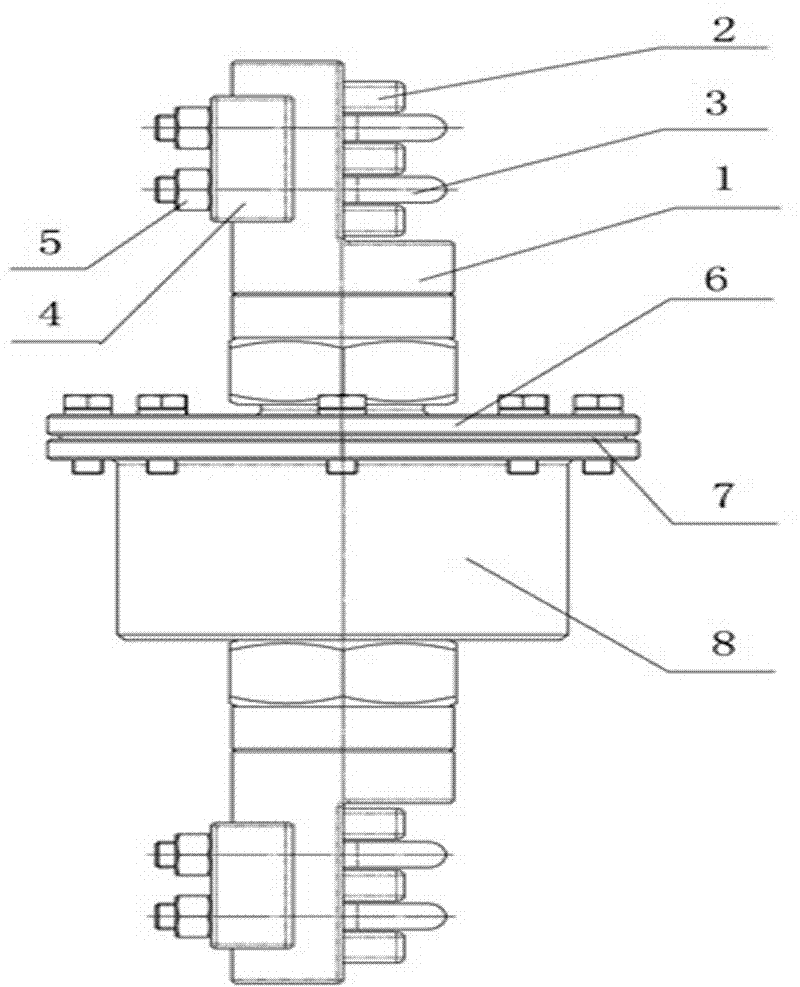

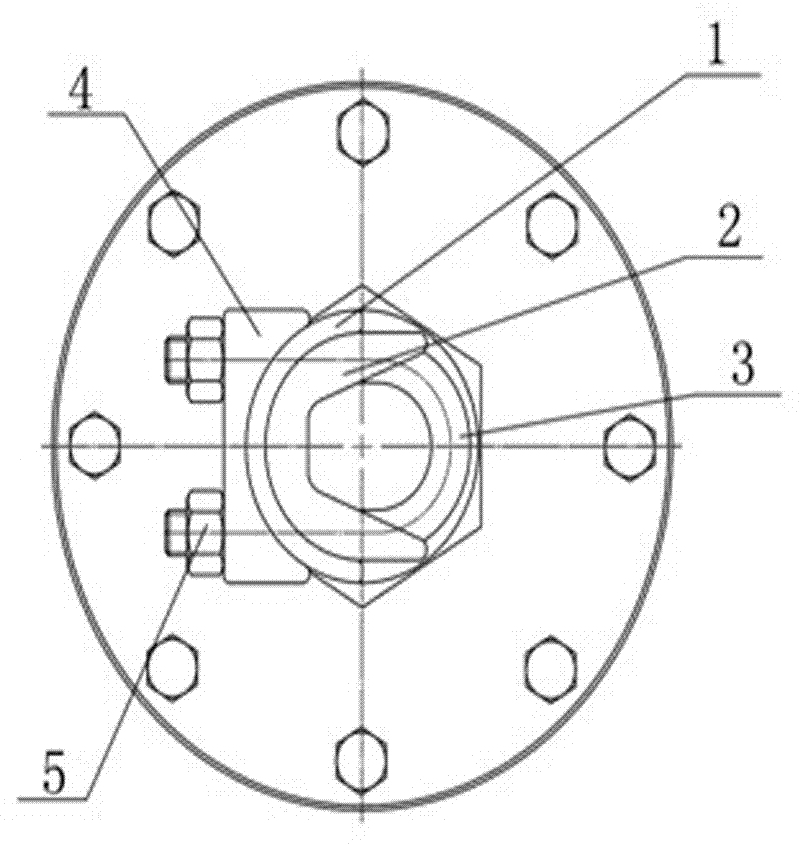

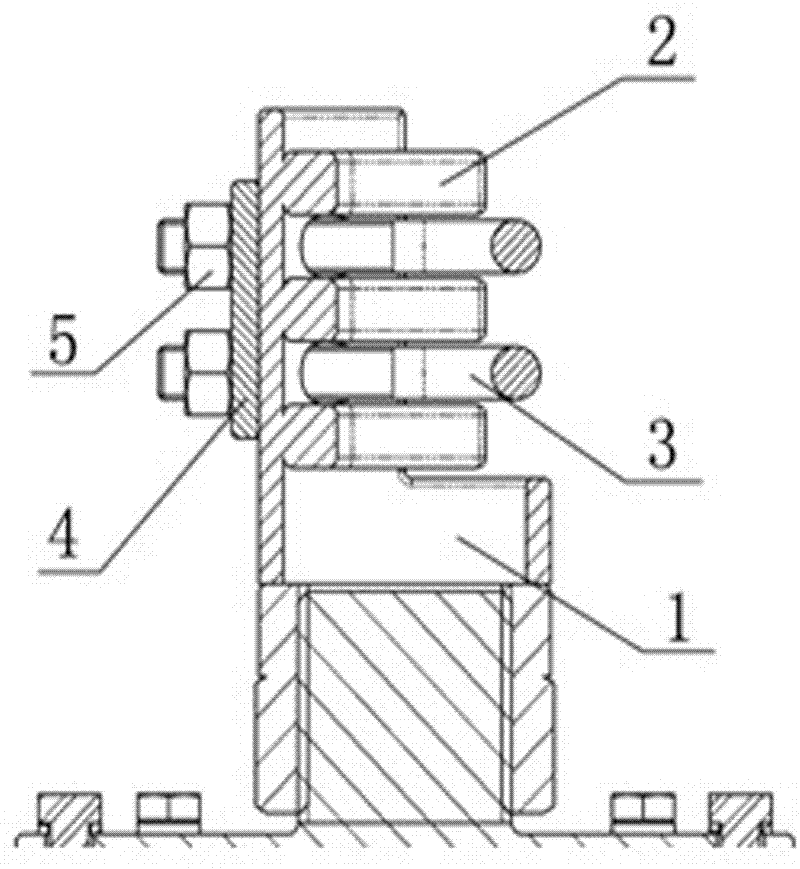

[0017] Such as Figure 1-4 As shown, a wire rope anti-twist connection device is implemented, which consists of two parts: a wire rope fixing device and a torsion release device. Among them, the wire rope fixing device is composed of threaded sleeve 1, trapezoidal groove 2, U-shaped card 3, pressure block 4, lock nut 5; the twist release device is composed of end cover 6, gasket 7, housing 8, rotating shaft 9, angle The contact bearing 10 and the thrust ball bearing 11 are constituted. Three trapezoidal grooves are evenly distributed and welded to the inner wall of one end of the threaded sleeve, and four through holes are drilled on the pipe wall between each trapezoidal groove, and the pressure blocks with the same four through holes are placed on the threaded sleeve correspondingly. On the outer wall of the pipe, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com