A rapid replacement method for burner bricks of annular heating furnace

A ring-shaped heating furnace and replacement method technology, which is applied in the direction of lighting and heating equipment, furnaces, furnace types, etc., can solve the problems that the construction quality and construction period cannot be guaranteed, and the burner bricks are difficult to locate and install, etc., so as to achieve good installation quality and maintenance The effect of less time and less downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] See Figure 1 to Figure 2 , a method for quickly replacing burner bricks in an annular heating furnace, which comprises the following steps,

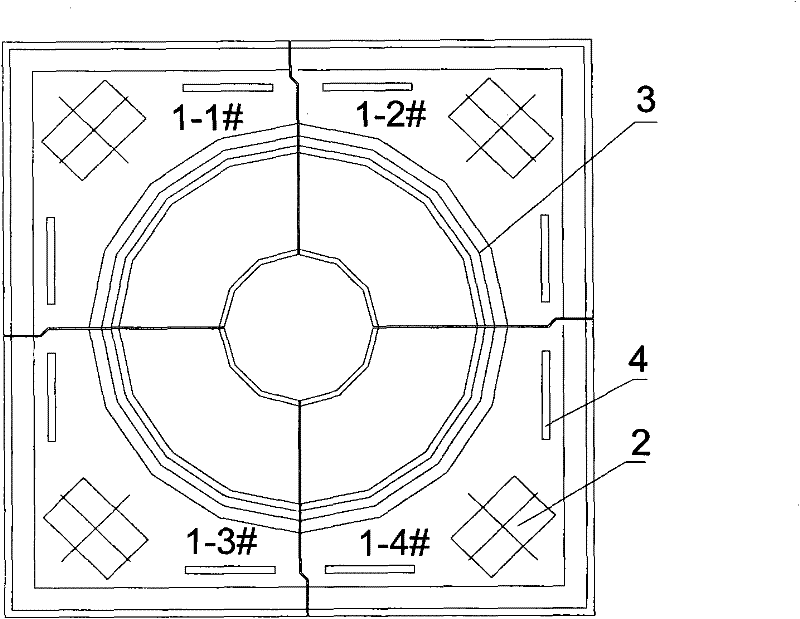

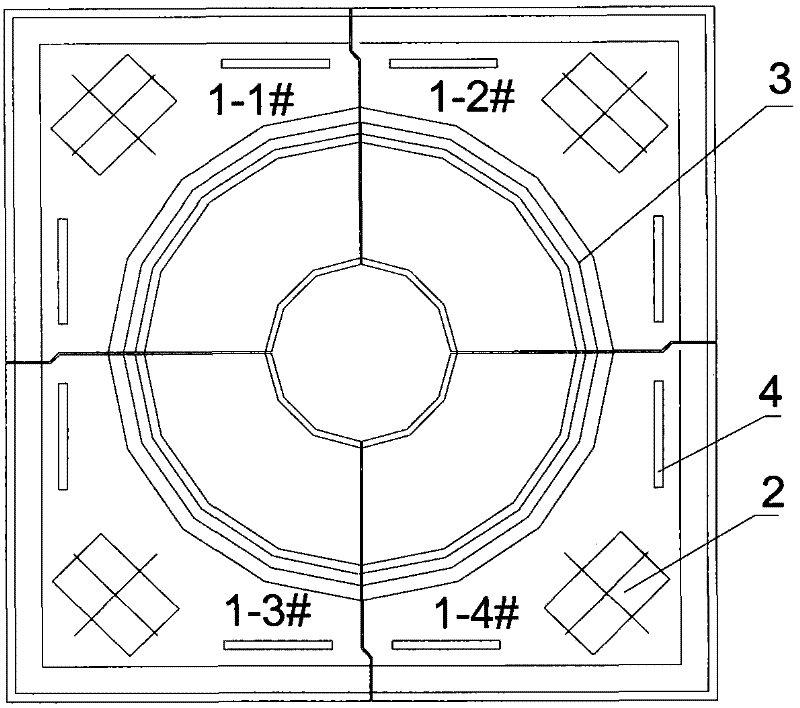

[0019] Offline prefabrication of special burner bricks, see figure 1 Shown in 1-1 # , 1-2 # , 1-3 # , 1-4 # . There are four prefabricated parts 1 in total, and each prefabricated part 1 is staggered and connected to avoid gas blow-by due to joints.

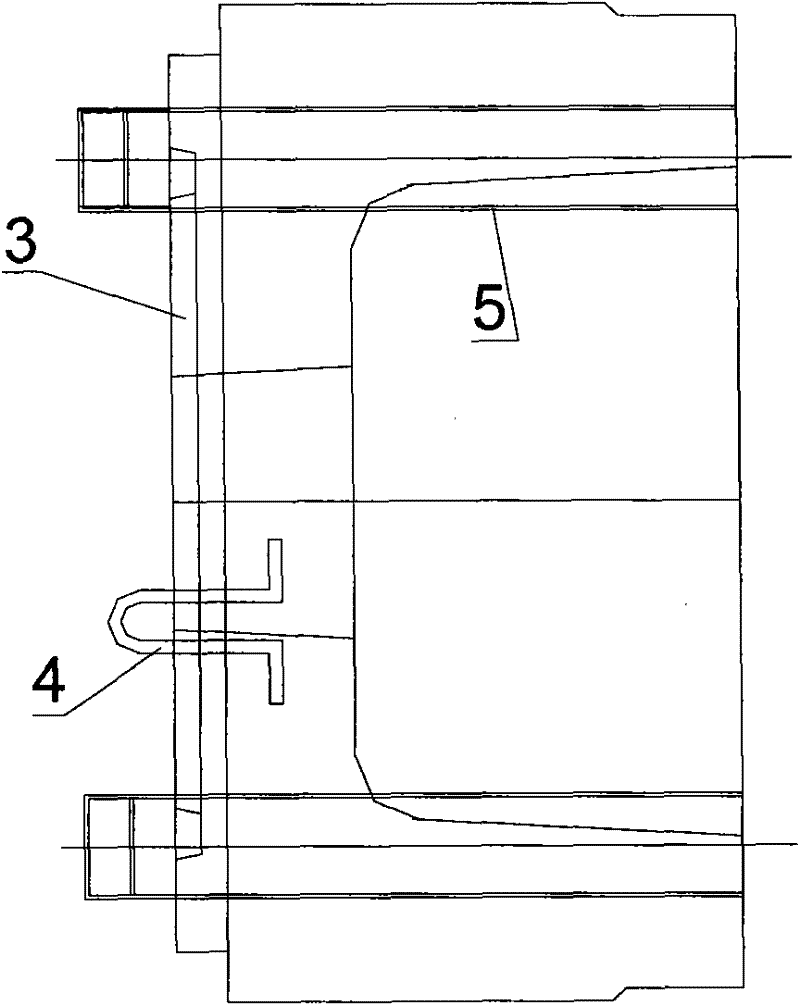

[0020] The anchor brick 2 is pre-embedded in the prefabricated part 1, and the fiber paper 5 is wrapped on the surface of the anchor brick 2 before installation and embedding. It is required that the head of the anchor brick 2 must be exposed to the end face of the prefabricated part. figure 2 .

[0021] When the prefabricated block is made, the metal fixing part 4 is inserted, which not only facilitates the installation of the burner brick, but also strengthens the connection between the quick-drying castable and the prefabricated block.

[0022] A slot with a certain dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com