A method of manufacturing touch screen bonding parts

A manufacturing process and a technology for laminating parts, which is applied in the field of improvement of touch screen anti-drop performance, can solve problems such as touch screen failure, electric field cannot be formed, and glass hardening cannot be achieved, so as to improve processing pass rate, improve drop resistance performance, and overall The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

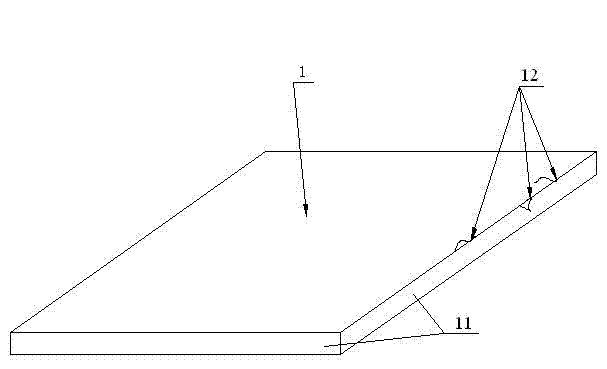

[0032] In order to make the content of the present invention more obvious and understandable, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

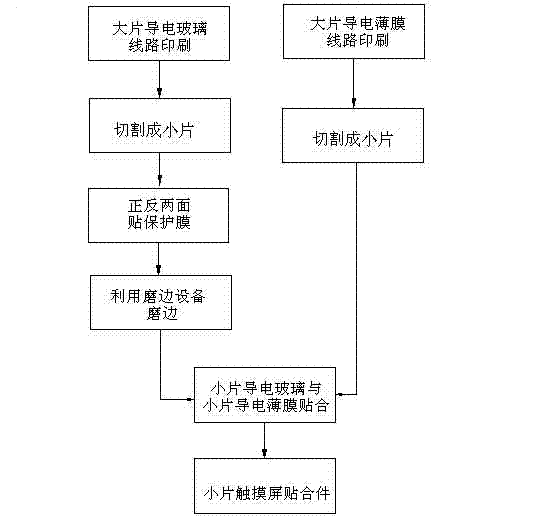

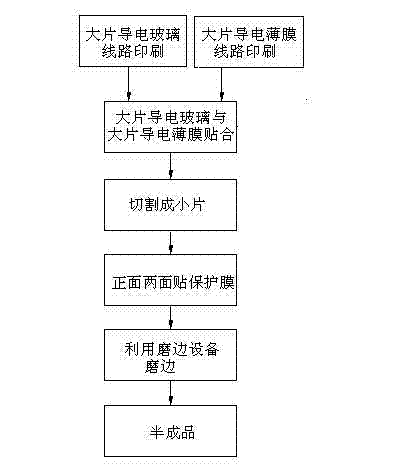

[0033] combine figure 1 , the manufacturing process method of the touch screen bonding part of the present invention, comprises the following steps:

[0034] (1). Print multiple corresponding functional circuit diagrams on large pieces of conductive glass and conductive film;

[0035] (2). Cut the large piece of conductive glass and conductive film that has been printed with the corresponding functional circuit diagram into small pieces of conductive glass and small pieces of conductive film suitable for a single touch screen;

[0036] (3). Use edging equipment to grind the cut small piece of conductive glass, so that the cut surface of each edge of the conductive glass is ground into a frosted curved surface;

[0037] (4). Bond the small piece of conductive glass and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com