Composite electrode plate for electrochemical reactor and manufacturing method thereof

A reactor and electrochemical technology, applied in the field of electrochemical engineering, can solve the problems of application limitation and inability to use one-time processing and molding, and achieve the effects of rapid processing method, good electrical conductivity, and easy batch processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings.

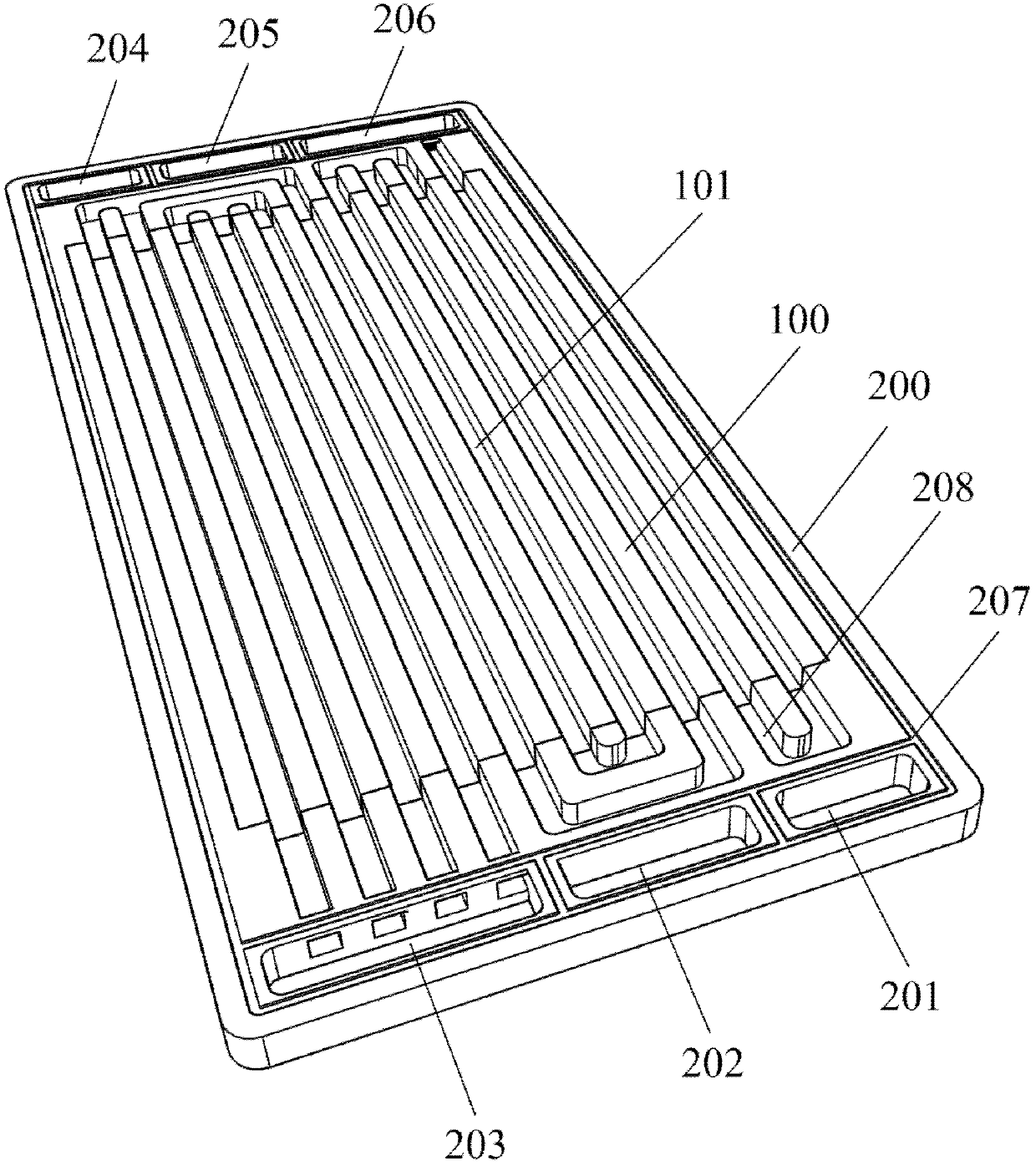

[0018] As shown in the accompanying drawings, the composite pole plate for electrochemical reactor includes a flow field plate 100, and the flow field plate 100 is a graphite pole plate with more than one parallel and straight-through flow field plate flow channel 101 on one plate surface or two plate surfaces. , the flow field plate 100 is embedded in the hollow frame of the pole plate frame 200, the outer surface of the flow field plate 100 is interference fit with the inner surface of the hollow frame of the pole plate frame 200, and the two ends of the flow field plate flow channel 101 The flow field distribution channels 208 on the plate surface of the pole plate frame 200 are connected one by one. 202. A combination of one or more of the oxidant inlet distribution pipe 203, the reducing agent outlet distribution pipe 204, the coolant outlet distribution pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com