Automatic releasing agent proportioning economizer for die casting machine

A technology of automatic proportioning and release agent, which is applied in the field of power saving, can solve the problems of low precision, increased maintenance, waste of raw materials, etc., and achieve the effects of reducing maintenance costs, saving electric energy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

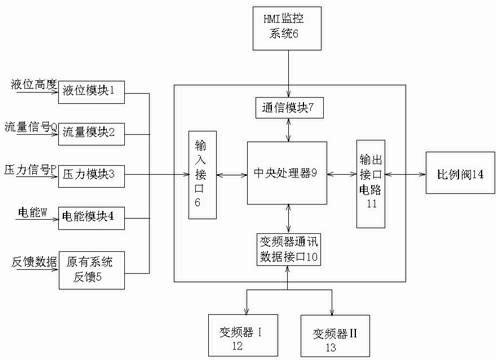

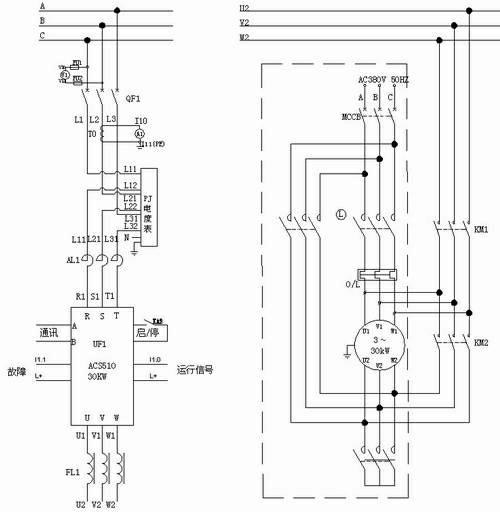

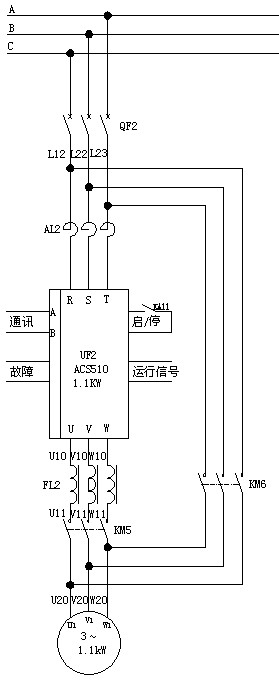

[0027] Further description will be made below in conjunction with the accompanying drawings.

[0028] see figure 1 , Die-casting machine release agent automatic proportioning energy saver includes liquid level sensor, flow sensor, pressure sensor, power transmitter, liquid level module 1, flow module 2, pressure module 3, power module 4, original system feedback 5, HMI monitoring system 6, communication module 7, input interface 8, central processing unit 9, frequency converter communication data interface 10, output interface circuit 11, frequency converter I12, frequency converter II13, proportional valve 14 and external execution unit. Among them, the liquid level sensor collects the liquid level height signal through the liquid level module 1 from the input interface 8 to the central processing unit 9, the flow sensor collects the flow signal Q from the input interface 8 to the central processing unit 9 through the flow module 2, and the pressure sensor collects the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com