Machining method for worm tooth profile of cutter shaft of large gear shaping machine

A processing method and gear shaper technology, applied in the field of mechanical processing, can solve the problems of increased parts size, weight, and inability to meet processing requirements, and achieve the effect of expanding the processing range, shortening the production cycle, and improving the technological level and operation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0025] See Figure 1 to Figure 5 .

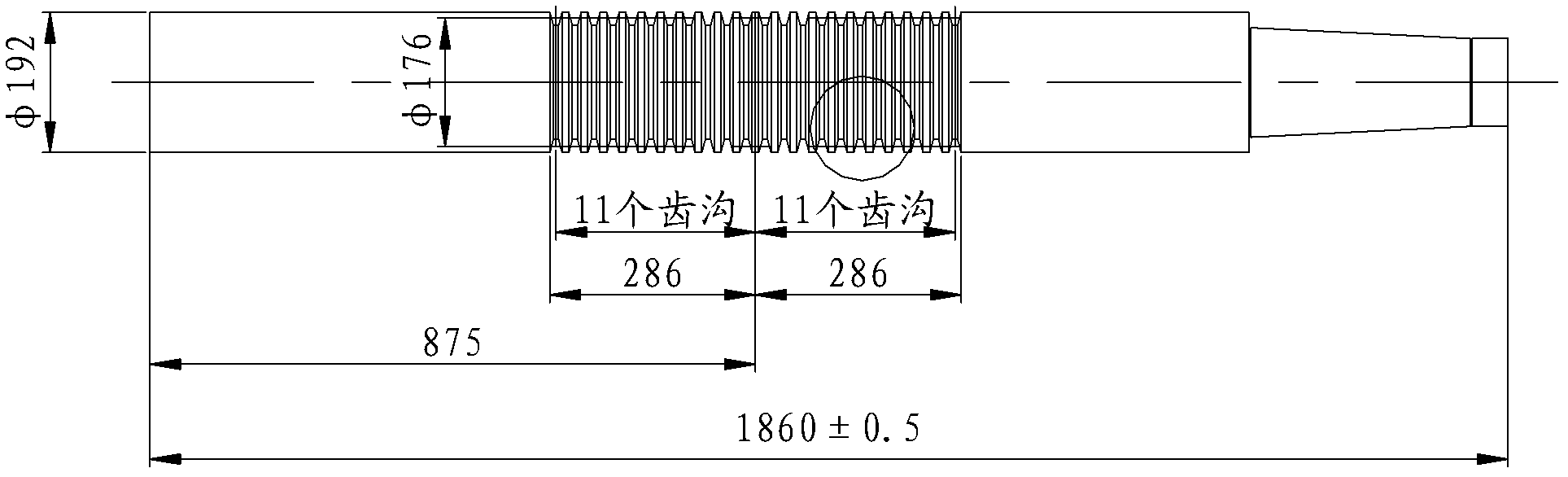

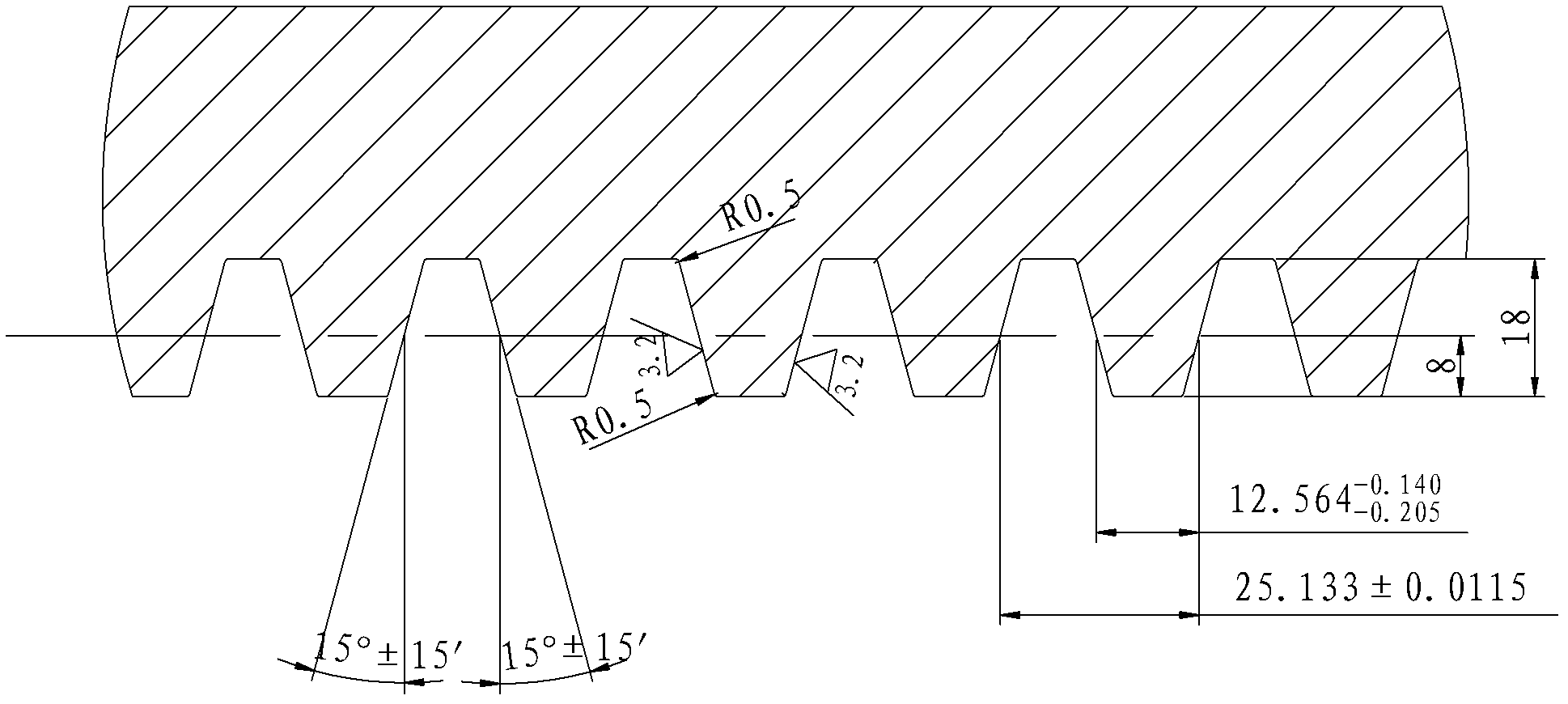

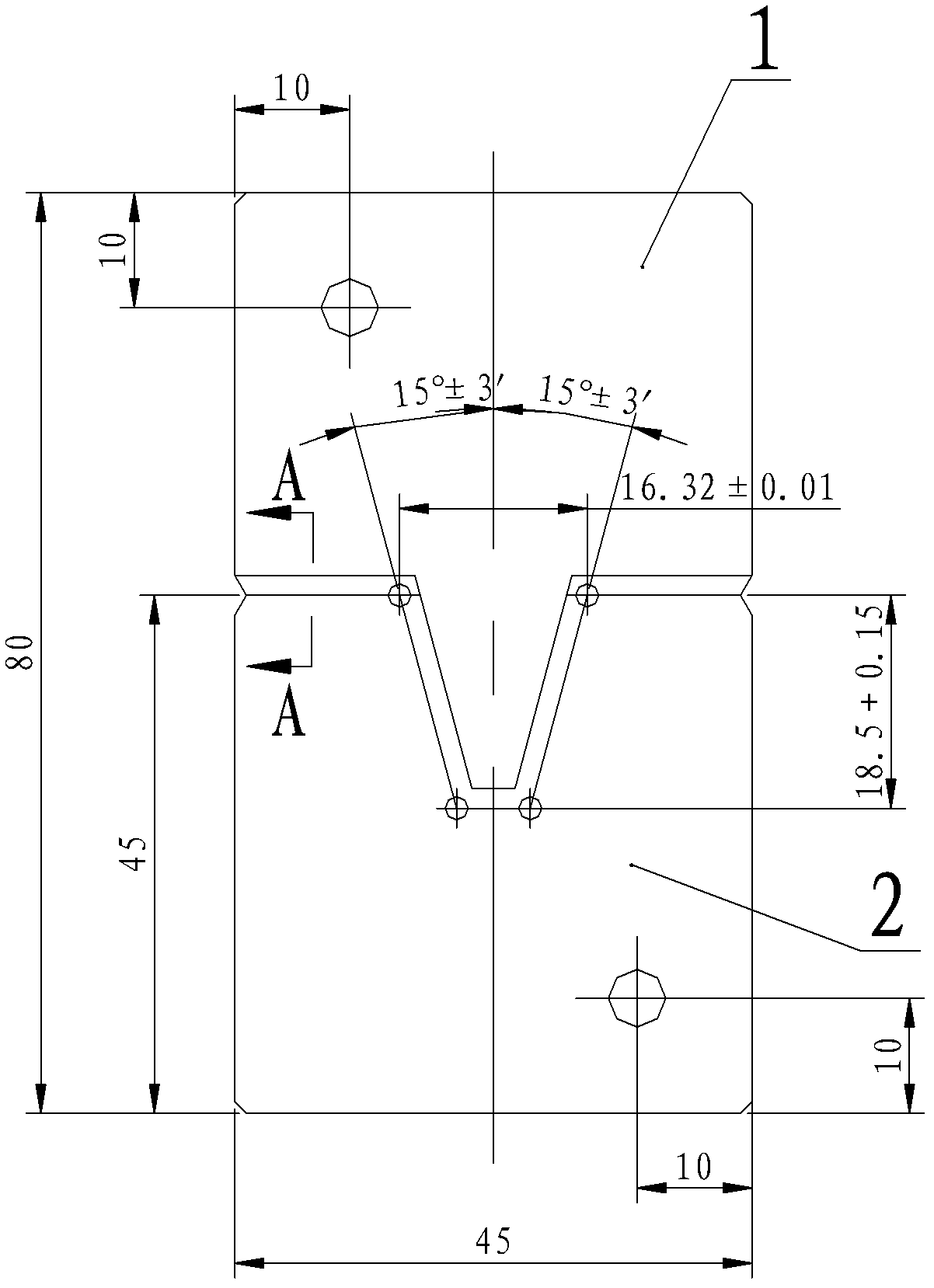

[0026] A processing method for the worm tooth profile of a large gear shaping machine shaft. The size, parameters and technical requirements of the processed large gear shaping machine shaft are: 1) Material: 20Cr; heat treatment: S0.9~C59 (except thread) ;2) Overall length: 1860±0.5; worm length: 572; number of teeth: 22; maximum diameter: 192; Pitch 25.133, pitch circle diameter 176, precision grade 6-D6, number of meshing gear teeth 78; 4) Technical requirements for worm tooth profile: a, radial runout tolerance of worm thread 0.017; b, worm thread axial The cumulative error of tooth pitch is ±0.02. The machining process of the cutter shaft parts is very complicated and there are twenty-six processes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com