Method for monitoring heat treatment temperature of power-up steel wire

A heat treatment temperature, electric-card technology, applied in the direction of heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of large wire heating temperature error, large human factor, large wire temperature control error, etc., to prevent wire heating Temperature error, high degree of automation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

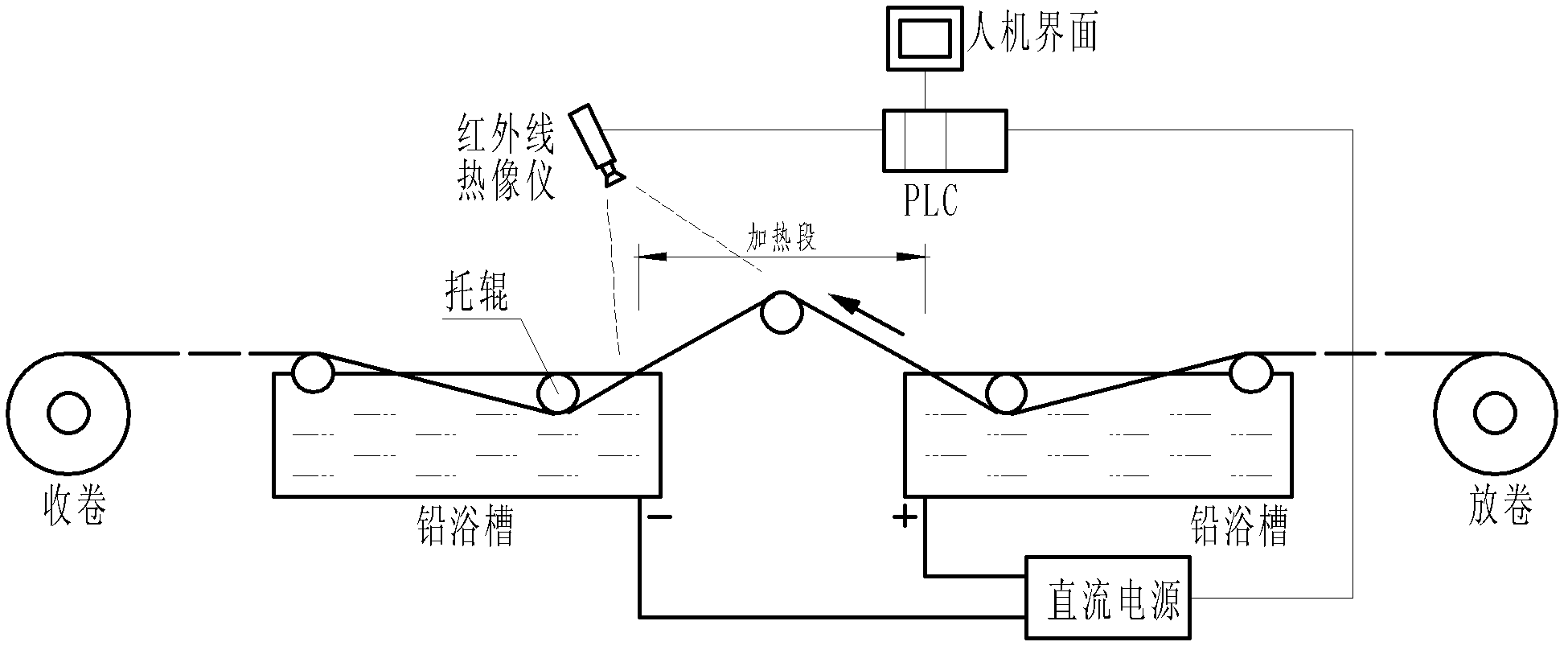

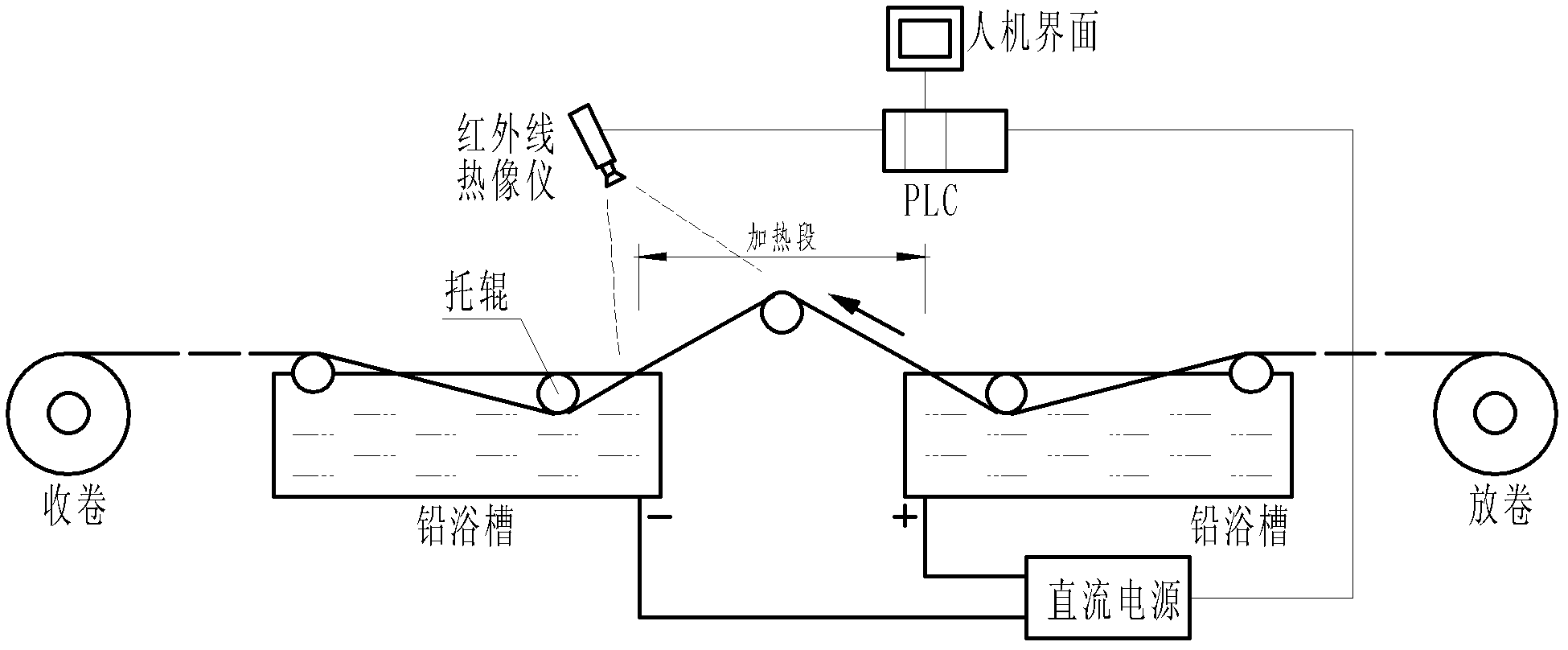

[0007] With the advancement of science and technology, the infrared thermal imaging cameras that have appeared in recent years have been able to meet the temperature measurement of high-temperature moving steel wires. The present invention uses infrared thermal imaging cameras to collect the temperature signals of steel wires, and controls the steel wires by PLC (programmable logic controller). The current is applied to automatically control the temperature of the steel wire.

[0008] The key equipment of the present invention is an infrared thermal imager. Although the price of this instrument is relatively expensive, it can measure the temperature of the steel wire in the heat treatment process very accurately. The monitoring of the heating temperature of steel wire heat treatment is the most suitable choice.

[0009] Technical scheme of the present invention is as follows:

[0010] Such as figure 1 The heat treatment flow chart of the steel wire is shown. When the steel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com